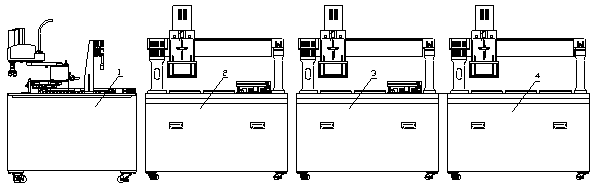

Semiconductor device assembly method and production line thereof

An assembly method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, conveyor objects, etc., can solve the problems of unguaranteed quality, easy deviation of parts, high labor intensity, etc., and reduce the amount of solder paste Unevenness, reduce labor intensity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] As one of the most basic implementations of the present invention, this embodiment discloses a semiconductor device assembly method and its production line. The semiconductor device assembly method includes the following steps:

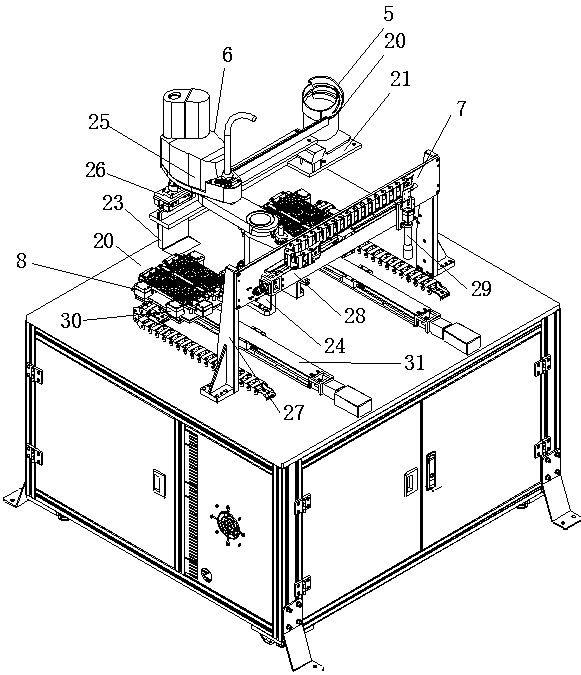

[0048] 1) Automatic assembly of lead wires: first install the graphite box on the lead wire installation device 8, then pour the lead wires into the vibrating plate 22, start the automatic lead wire assembly equipment through the PLC controller, the automatic lead wire assembly equipment automatically completes the lead wire assembly, and then put the stone cartridge removal;

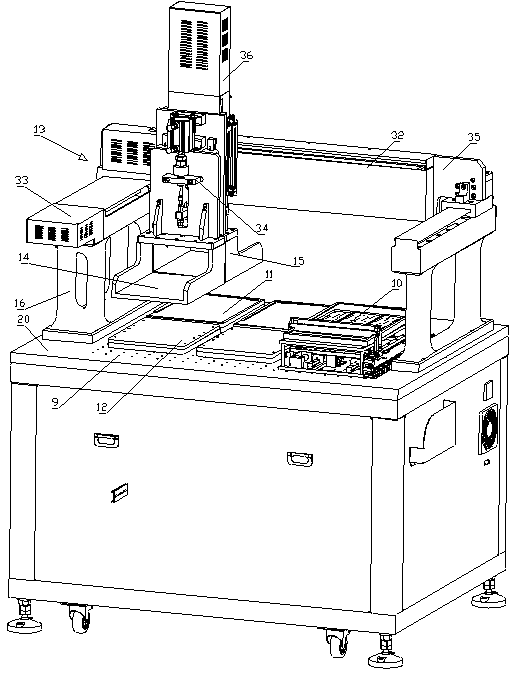

[0049] 2) Dispensing of lead wires and assembly of the lower connecting piece: first install the graphite box that has completed the lead wire assembly on the positioning tool 12 of the graphite box, and then shake the lower connecting piece into the connecting piece sieve plate 11 and install it The connecting piece sieve plate 11 of the connecting piece is installed on...

Embodiment 2

[0055] As a preferred embodiment of the present invention, this embodiment discloses a semiconductor device assembly method and its production line. The semiconductor device assembly method includes the following steps:

[0056] 1) Automatic assembly of lead wires: first install the graphite box on the lead wire installation device 8, then pour the lead wires into the vibrating plate 22, start the automatic lead wire assembly equipment through the PLC controller, the automatic lead wire assembly equipment automatically completes the lead wire assembly, and then put the stone cartridge removal;

[0057] 2) Dispensing of lead wires and assembly of the lower connecting piece: first install the graphite box that has completed the lead wire assembly on the positioning tool 12 of the graphite box, and then shake the lower connecting piece into the connecting piece sieve plate 11 and install it The connecting piece sieve plate 11 of the connecting piece is installed on the lead dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com