Chili pepper cleaning and degerming method

A pepper and washing machine technology, applied in food preservation, food ultrasonic treatment, preservation of fruits/vegetables through radiation/electrical treatment, etc. Inorganic salt content, accelerated decomposition, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

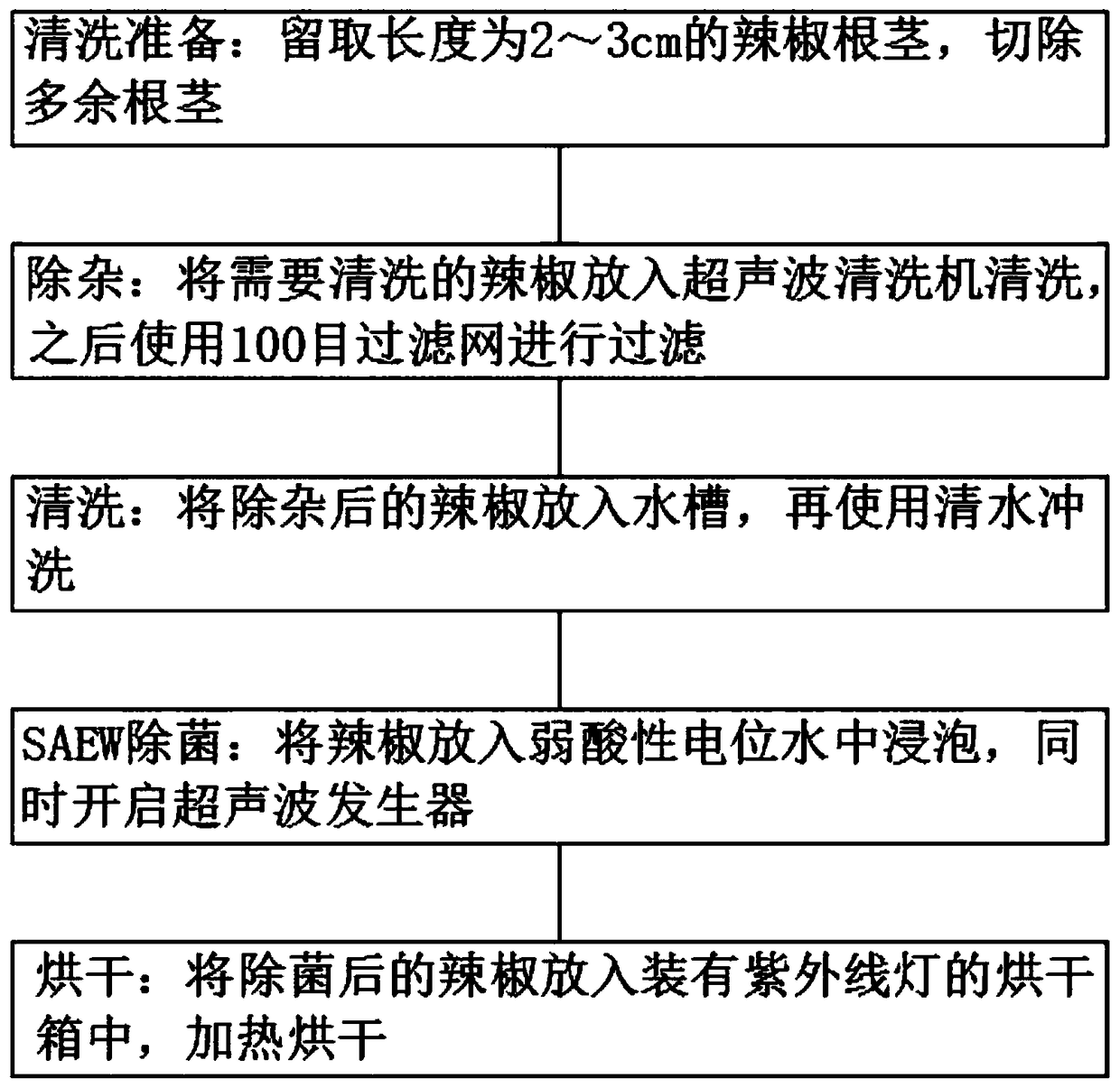

[0031] Such as figure 1 shown, including the following steps:

[0032] (1), cleaning preparation: take the capsicum rhizome that length is 2cm, cut off excess rhizome;

[0033] (2) Impurity removal: Put the peppers to be cleaned into an ultrasonic cleaning machine for ultrasonic cleaning, and then use a 100-mesh filter to filter. The ultrasonic cleaning includes the following steps:

[0034] (2.1), first put the pepper into the cleaning tank, then add distilled water, and then use an iron sieve to press the pepper into the water to complete the impurity removal preparation;

[0035] (2.2), add H to the water that completes impurity removal preparation 2 o 2 , H 2 o 2 : Add 9 mL of 10% H 2 o 2 solution, turn on the ultrasonic cleaner for cleaning;

[0036] (3) Cleaning: put the cleaned peppers into the water tank, and rinse them with clean water at a temperature of 38°C for 9 minutes;

[0037] (4), drying: the capsicum after cleaning is put into the drying box that ult...

Embodiment 2

[0039] Such as figure 1 shown, including the following steps:

[0040] (1), cleaning preparation: take the capsicum rhizome that length is 2cm, cut off excess rhizome;

[0041] (2) Impurity removal: Put the peppers to be cleaned into an ultrasonic cleaning machine for ultrasonic cleaning, and then use a 100-mesh filter to filter. The ultrasonic cleaning includes the following steps:

[0042] (2.1), first put the pepper into the cleaning tank, then add distilled water, and then use an iron sieve to press the pepper into the water to complete the impurity removal preparation;

[0043] (2.2), add H to the water that completes impurity removal preparation 2 o 2 , H 2 o 2 : Add 9 mL of 10% H 2 o 2 solution, turn on the ultrasonic cleaner for cleaning;

[0044] (3) Cleaning: put the cleaned peppers into the water tank, and rinse them with clean water at a temperature of 38°C for 9 minutes;

[0045] (4) Ultrasonic sterilization: turn on the ultrasonic generator to emit ultra...

Embodiment 3

[0048] Such as figure 1 shown, including the following steps:

[0049] (1), cleaning preparation: take the capsicum rhizome that length is 2cm, cut off excess rhizome;

[0050] (2) Impurity removal: Put the peppers to be cleaned into an ultrasonic cleaning machine for ultrasonic cleaning, and then use a 100-mesh filter to filter. The ultrasonic cleaning includes the following steps:

[0051] (2.1), first put the pepper into the cleaning tank, then add distilled water, and then use an iron sieve to press the pepper into the water to complete the impurity removal preparation;

[0052] (2.2), add H to the water that completes impurity removal preparation 2 o 2 , H 2 o 2 : Add 9 mL of 10% H 2 o 2 solution, turn on the ultrasonic cleaner for cleaning;

[0053] (3) Cleaning: put the cleaned peppers into the water tank, and rinse them with clean water at a temperature of 38°C for 9 minutes;

[0054] (4), SAEW sterilization: soak the cleaned peppers in weakly acidic potential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com