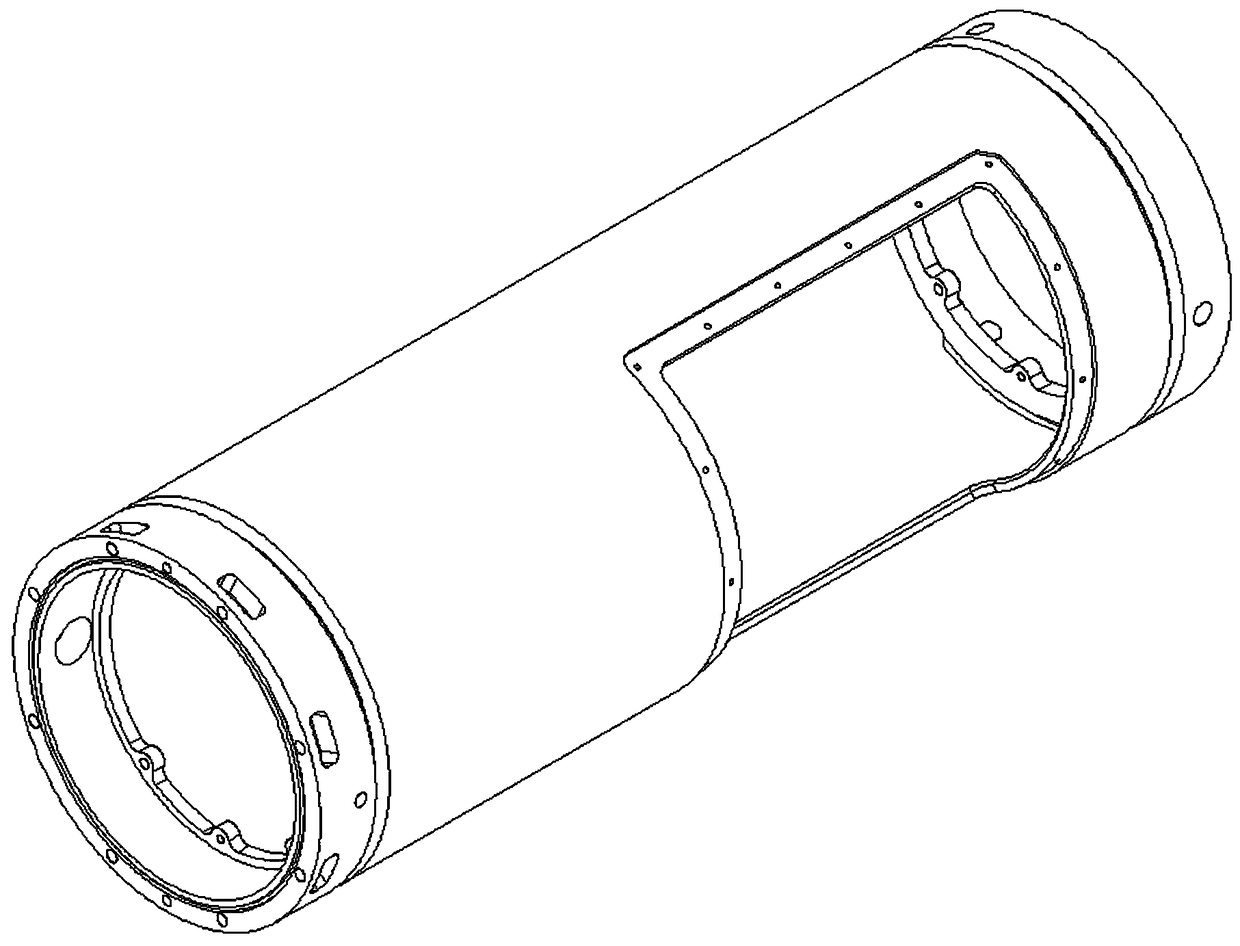

Consumable electrode mixed gas protective automated welding method for large-scale thick-walled structural part

An automatic welding and gas mixing technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, low production efficiency, poor quality of weld joints, etc., to achieve simple operation, reduce labor intensity, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] A method for automatic welding of large thick-walled structural parts with mixed gas shielded melting electrode, the method comprising the following steps:

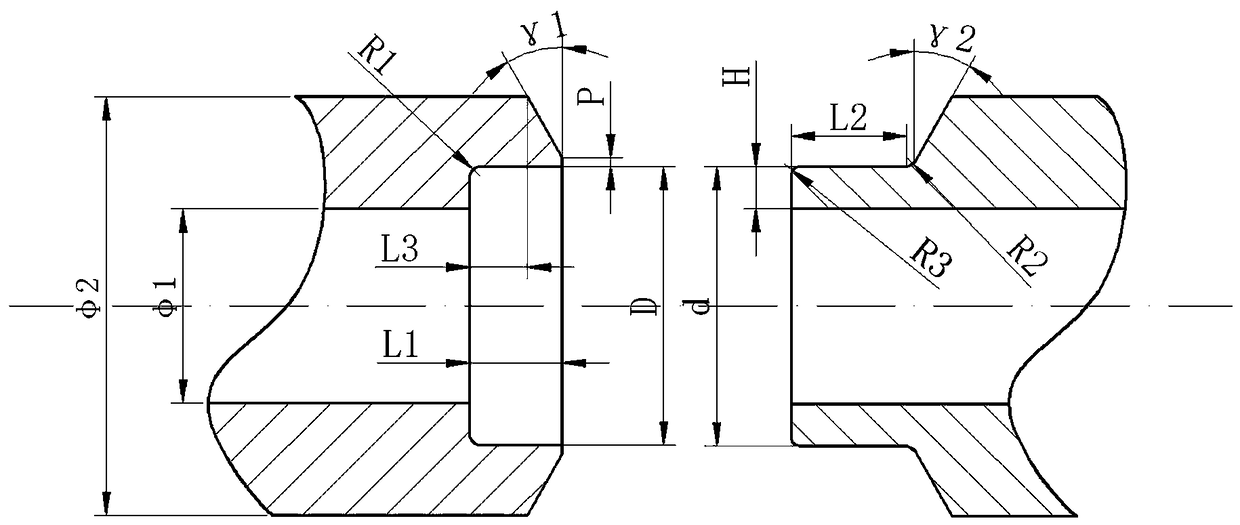

[0032] (A), process the welding part of the structure to be welded to open a U-shaped groove, such as figure 2 ;

[0033] (B) Sandblasting the parts to be welded before welding to remove oil and rust pollutants on the surface of the parts;

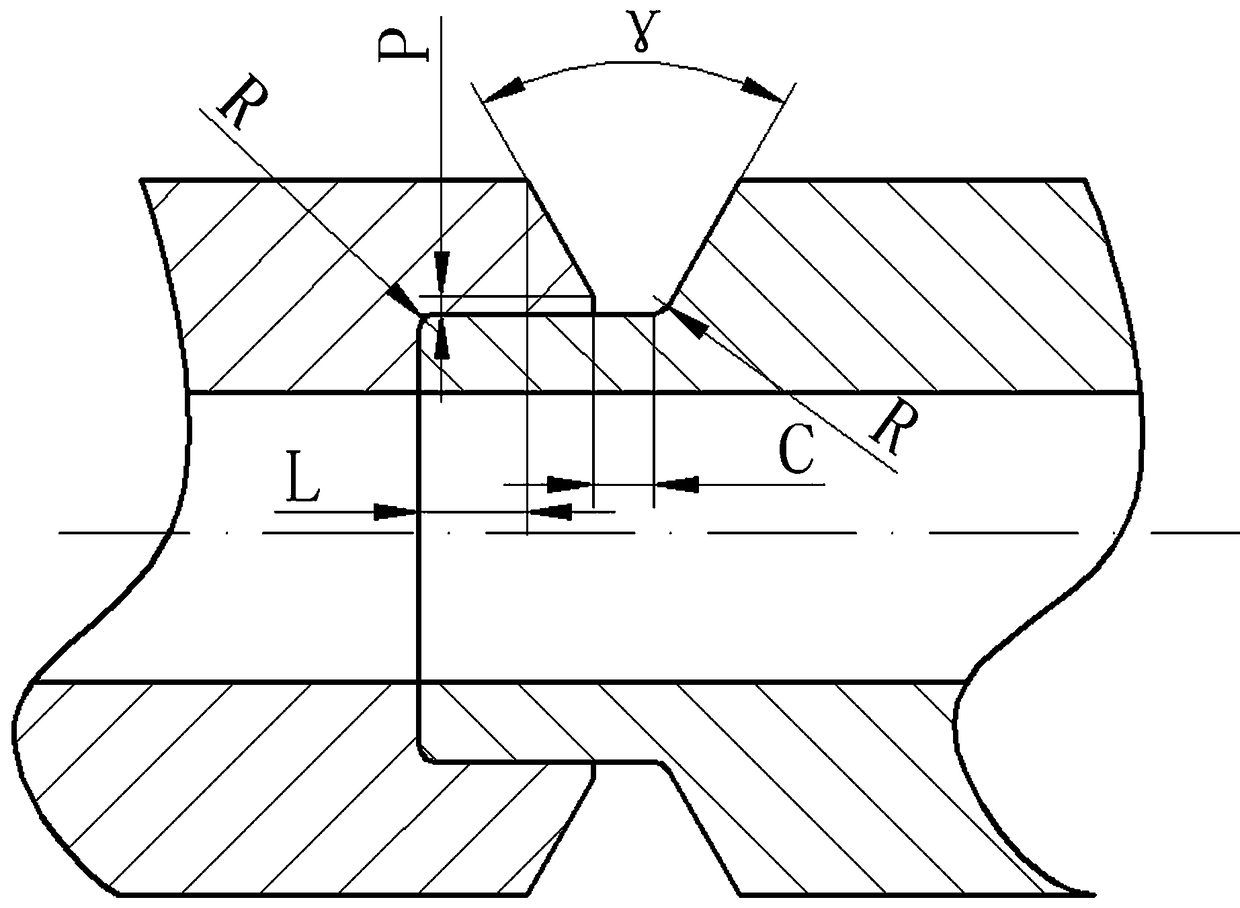

[0034] (C) Assemble the parts, the weld joint structure adopts the bottom-lock welding joint method, and the welding repair gap is controlled by the size of the parts themselves, and the assembly method adopts interference fit, such as image 3 ;

[0035] (D) Turn on the power switch of the welding equipment, place the assembled parts to be welded on the welding tool, clamp one end of the part with a three-jaw chuck, and tighten the other end with a cylinder; adjust the ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com