Once turning and milling combined cutting device

A cutting device, a one-time technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems that affect the processing quality and efficiency of parts, the number of repeated clamping of workpieces, and the poor positioning accuracy of tool holders, etc., to improve Production efficiency, improvement of equipment processing range, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

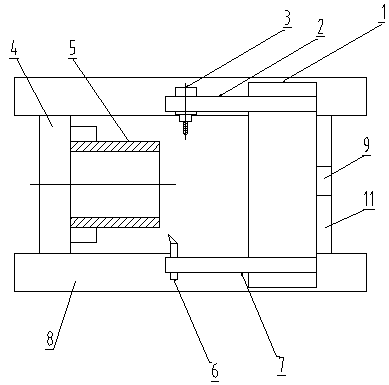

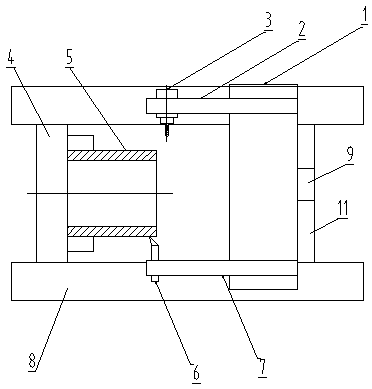

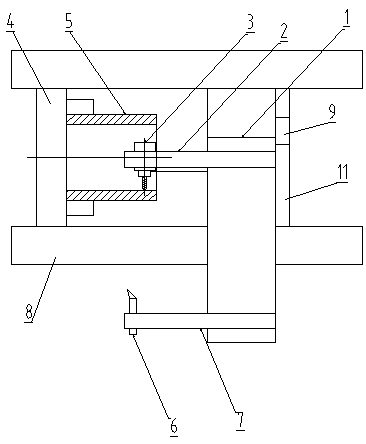

[0018] The present invention includes a carriage 8 in a lathe, and a support plate 1 that moves forward and backward along the carriage 8 in the lathe is provided on the carriage 8 in the lathe;

[0019] The support plate 1 is provided with a power milling head tool holder 2 and a turning tool tool holder 7 that can move left and right along the support plate 1, a power milling head 3 is installed on the power milling head tool holder 2, and the turning tool tool Turning tool 6 is installed on the frame 7;

[0020] A fixture 4 for installing a workpiece 5 is fixedly arranged on the carriage 8 in the lathe, and the workpiece 5 is arranged opposite to the power milling head 3 and the turning tool 6 .

[0021] The turning tool holder 7 and the milling head tool holder 2 are segmented structures, including a heavy rod and a light rod connected together, the heavy rod is connected on the support plate 1, and the light rod is used to set the power milling rod. Head 3 and turning to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com