A beverage can recycling packing machine

A beverage can and feeding device technology, which is applied in the field of beverage can recycling baler and beverage can recycling and packaging, can solve problems such as damage to the beverage can machine, failure to close the feeding port, interruption of the compression and packaging program, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

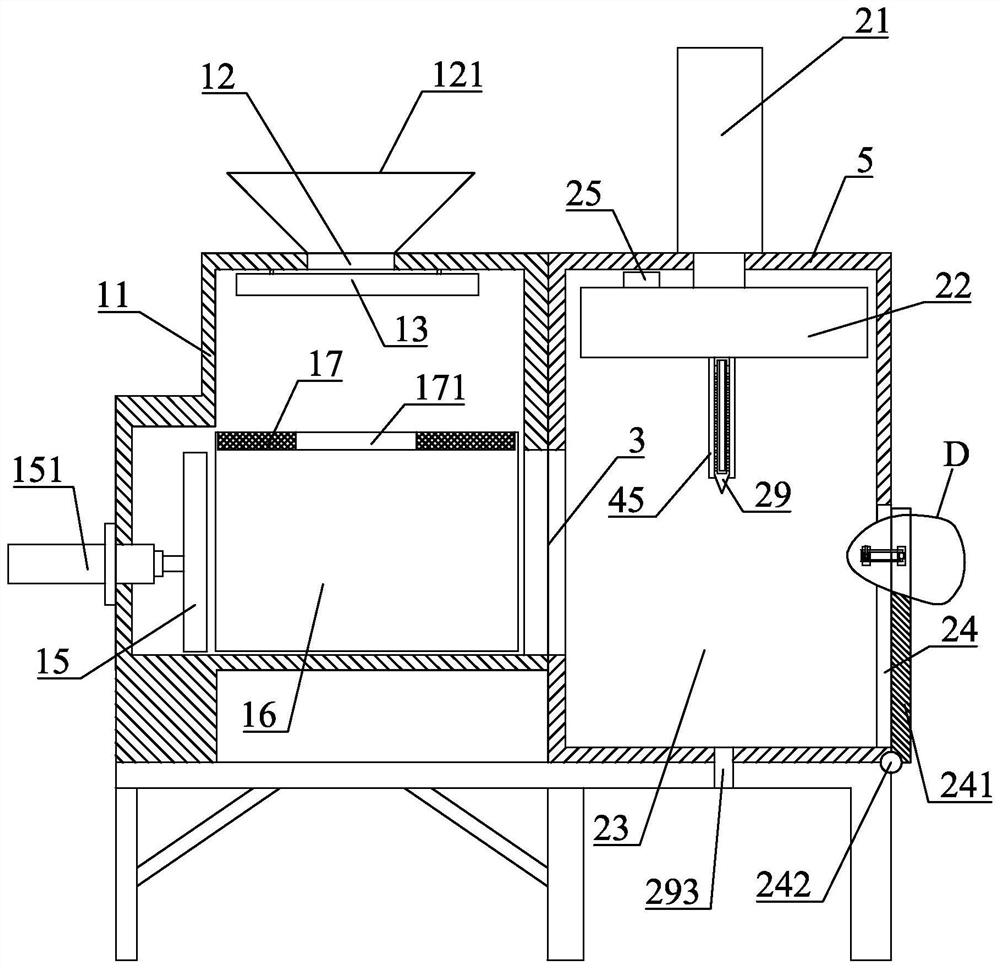

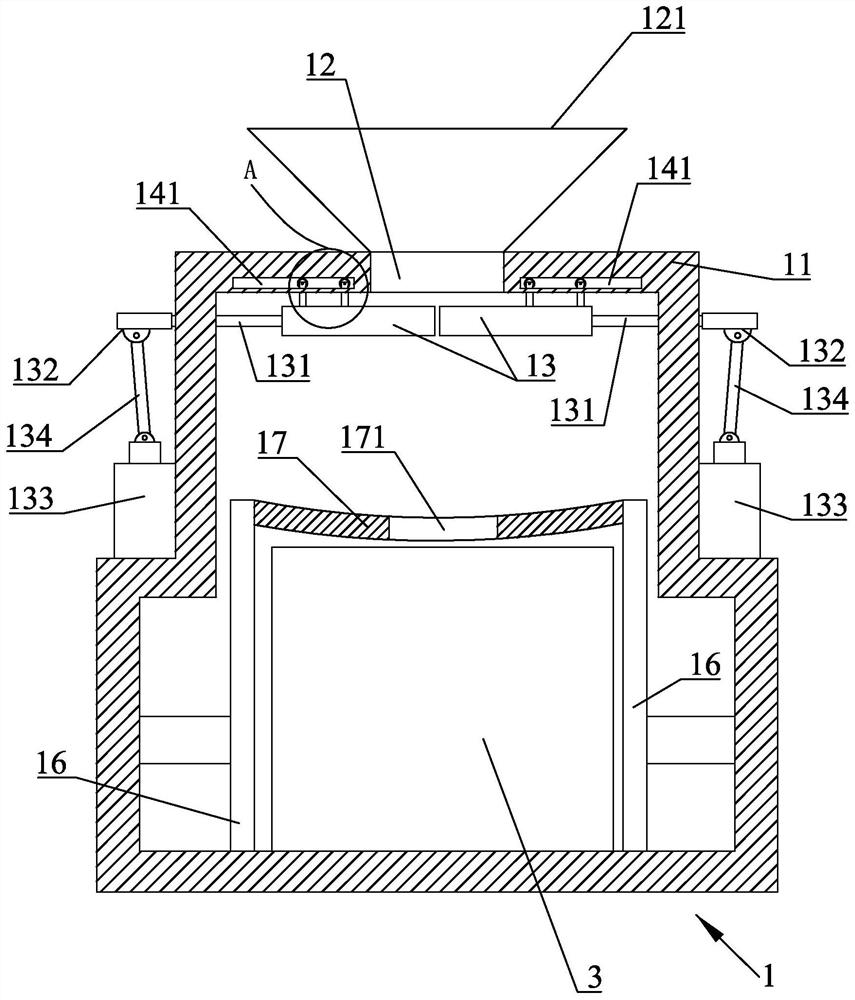

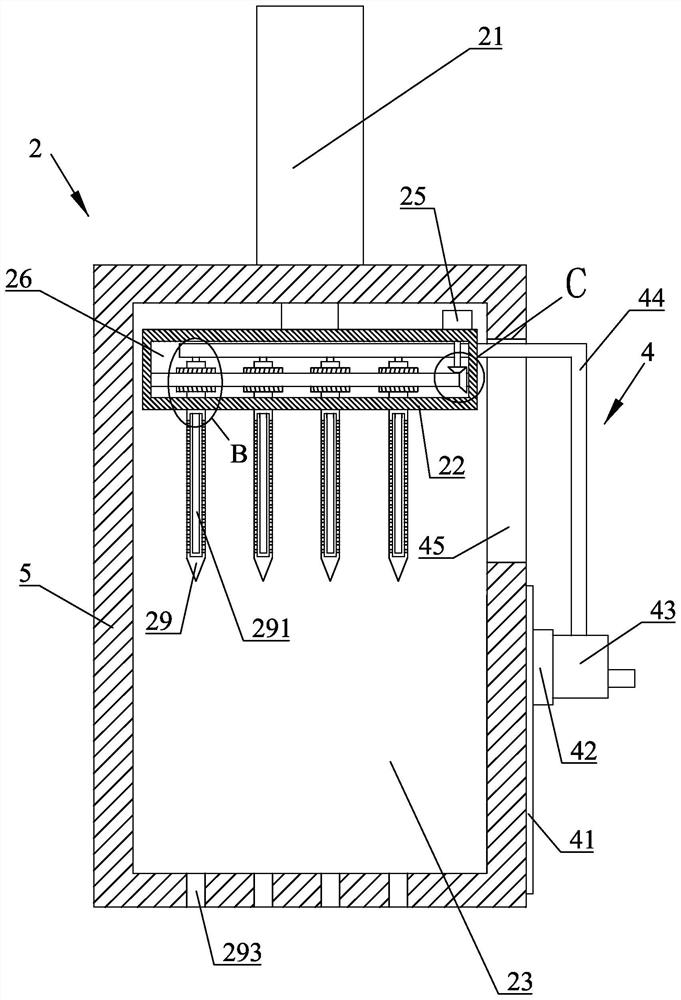

[0038] Such as Figure 1 to Figure 10 As shown, it is a beverage can recycling packaging machine related to the present invention, which includes a feeding device 1 and an extruding device 2, and there is a passage between the feeding device 1 and the extruding device 2 for the beverage can to pass through. Channel 3, the feed device 1 includes a first housing 11, the top of the first housing 11 is provided with a feed channel 12, and a conical hopper communicated with the feed channel 12 is arranged above the feed channel 12 121 , the beverage cans to be packaged are placed in the conical hopper 121 , and due to the effect of gravity, the beverage cans in the conical hopper 121 will automatically enter into the feeding channel 12 .

[0039] Two baffles 13 are symmetrically slidably connected in the first shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com