Tread rubber for all-steel truck radial tire and preparation method thereof

A radial tire and tread rubber technology is applied to the tread rubber of an all-steel truck radial tire and its preparation field. Reaction active point, reduce energy consumption, make up for the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The embodiment of the present invention also provides the above-mentioned preparation method for the tread rubber of the all-steel radial truck tire, comprising the following steps:

[0042] S1 Preparation of wet mixed rubber: disperse carbon nanotubes, graphene and cracked carbon black in water by ultrasonic treatment to form a filler slurry, mix the filler slurry with natural rubber by high-pressure jetting, and place it in a coagulation reactor Condensation in medium, dehydration and drying after coagulation, to obtain wet-mixed glue;

[0043] S2 three-stage mixing: add the above-mentioned wet mixed rubber, base rubber, active agent, carbon black, white carbon black, silane coupling agent and anti-aging agent together to mix in an internal mixer to obtain a master batch; Said one-stage masterbatch is added into internal mixer and mixed to obtain second-stage masterbatch; said second-stage masterbatch, accelerator and vulcanizing agent are added to internal mixer and ...

Embodiment 1

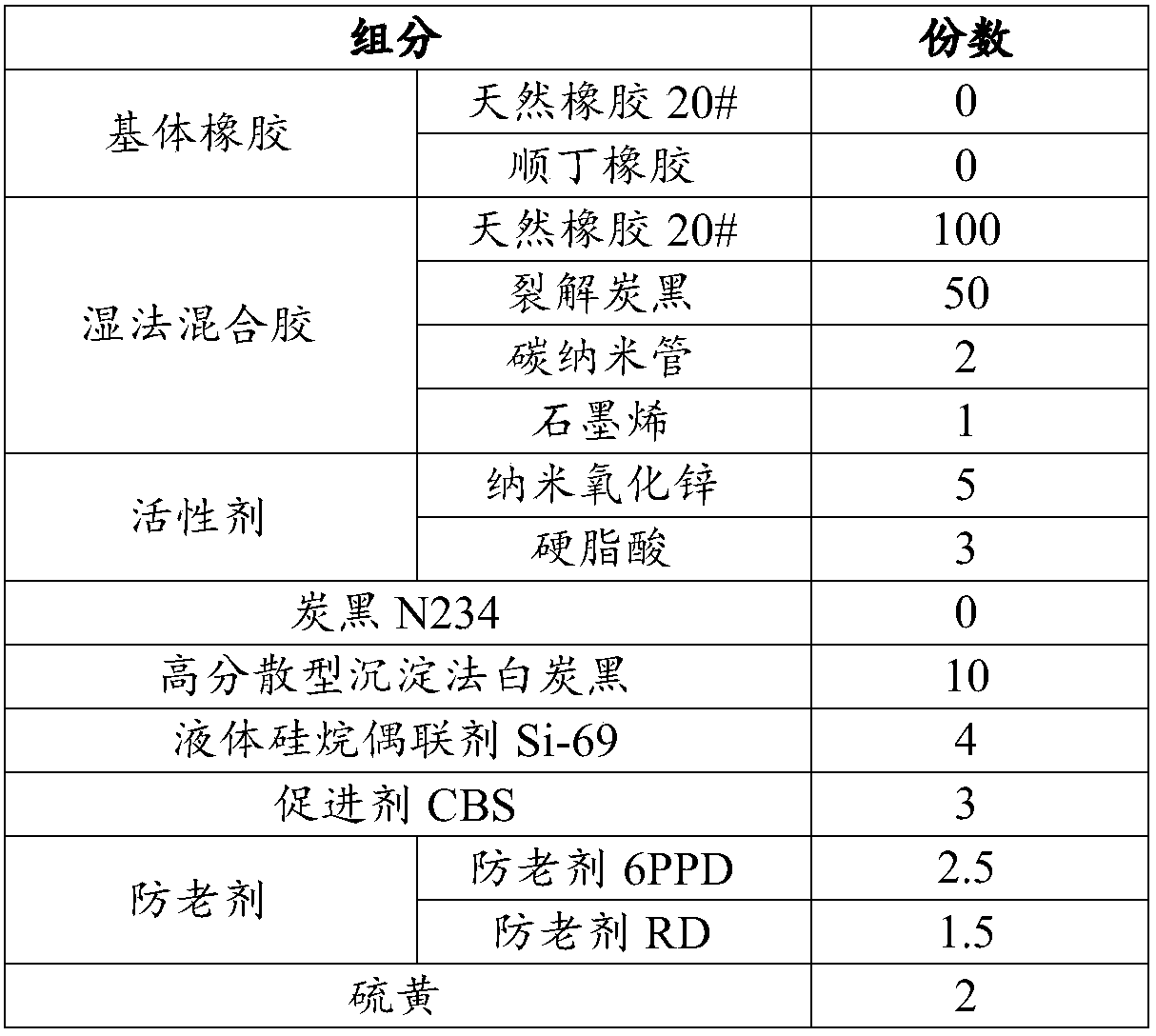

[0047] Tread rubber for all-steel radial truck tires, including the following components by weight:

[0048] The proportion of each component of tread rubber in Table 1 Example 1

[0049]

[0050] Among them, the diameter of carbon nanotubes is 30-50nm, and the length is 0.5-2μm; the thickness of graphene sheets is 1-4nm, and the two-dimensional size is 100-400nm; pyrolysis carbon black is waste tire thermal cracking carbon black, its The absorption value of dibutyl phthalate is (80~100)×10 -5 m 3 / kg, the iodine absorption value is 80~130g / kg, and the specific surface area is 60~80m 2 / g, heating loss at 125°C is 0.5% to 1.5%; nano-zinc oxide includes 80% primary particles with a particle size below 100nm and 20% primary particles with a particle size above 100nm; the specific surface area of white carbon black is 120 ~200m 2 / g, the absorption value of dibutyl phthalate is 2.00~3.50cm 3 / g; when the white carbon black is dispersed in water to form a 5% aqueous solu...

Embodiment 2

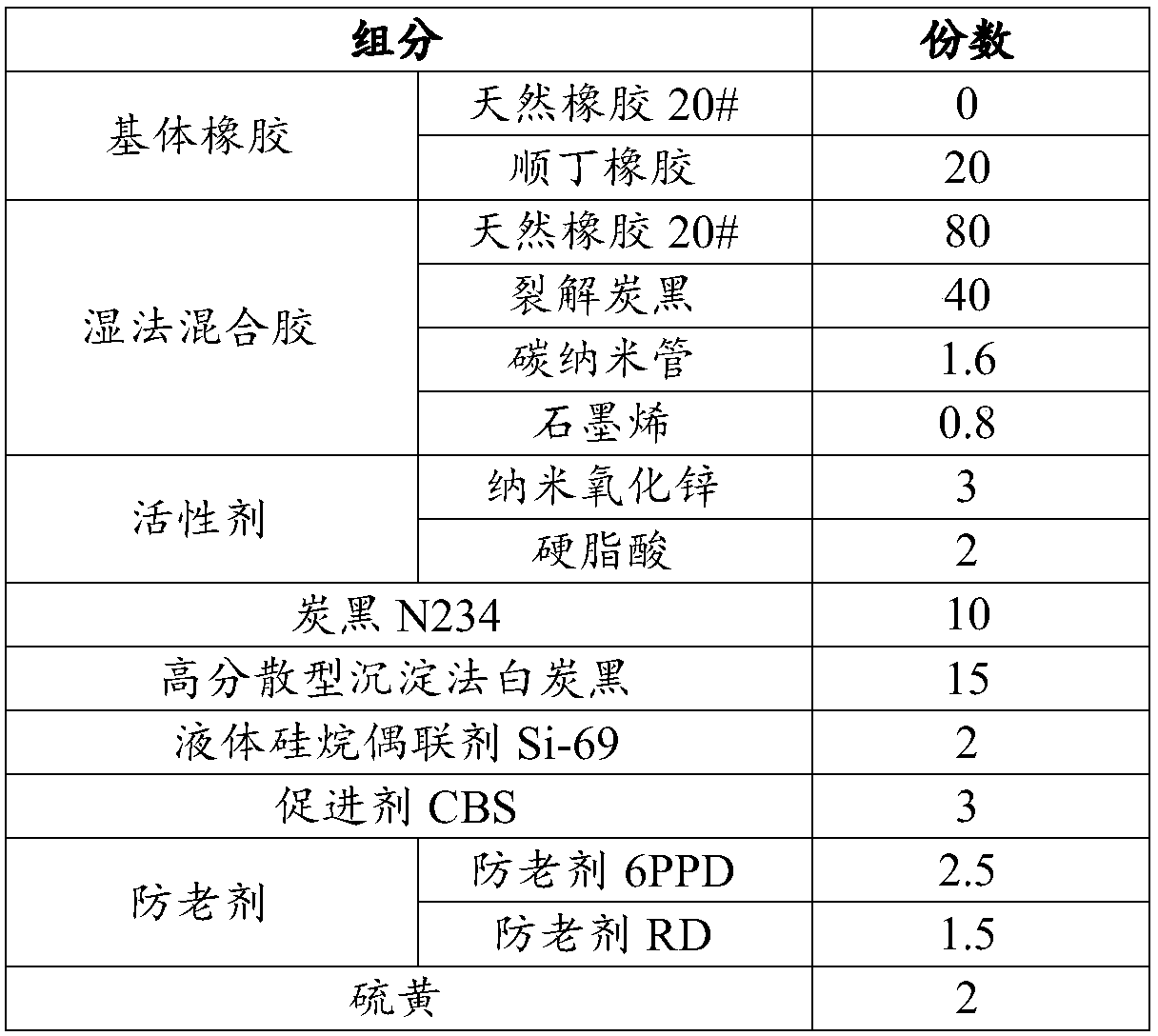

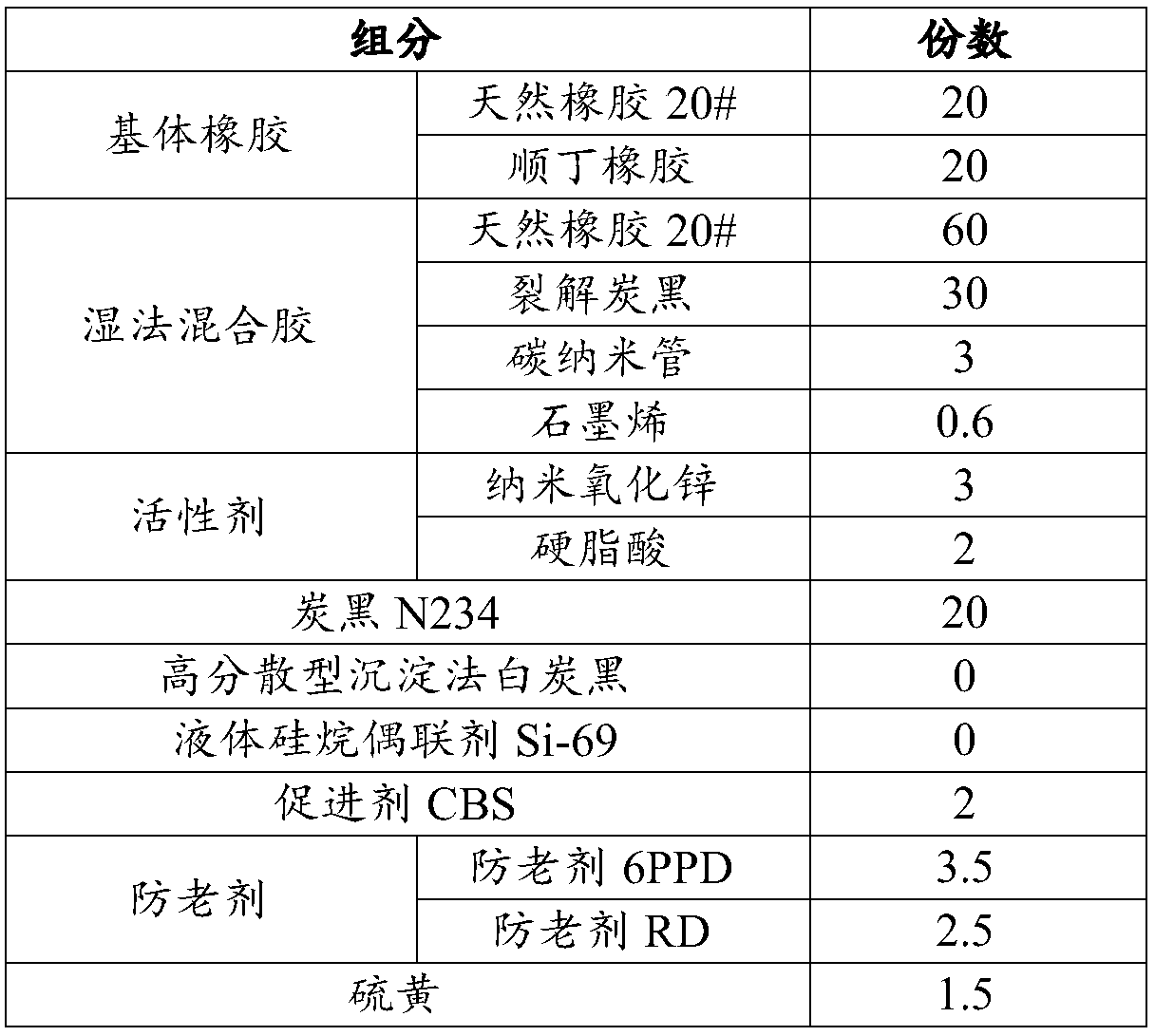

[0055] Tread rubber for all-steel radial truck tires, including the following components by weight:

[0056] Each component distribution ratio of tread rubber in table 2 embodiment 2

[0057]

[0058] Wherein, the cis content of the butadiene rubber is more than 96%; the selection of other components is the same as in Example 1.

[0059] The above-mentioned preparation method for the tread rubber of all-steel radial truck tire comprises the following steps:

[0060] (1) Preparation of wet mixed rubber: disperse carbon nanotubes, graphene and pyrolysis carbon black in water by ultrasonic treatment to form filler water slurry, mix filler water slurry with natural rubber 20# through high-pressure jetting, and place in coagulation Coagulation is carried out in the reactor, after coagulation, dehydration and drying are carried out to obtain wet-mixed glue;

[0061] (2) Three-stage mixing: add the above-mentioned wet mixed rubber with matrix rubber, active agent, carbon black N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com