Corrugated pipe azimuth adjustment displacement detection device and method thereof

A technology of displacement detection and orientation adjustment, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low degree of automation, high price of laser three-dimensional scanning sensors, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

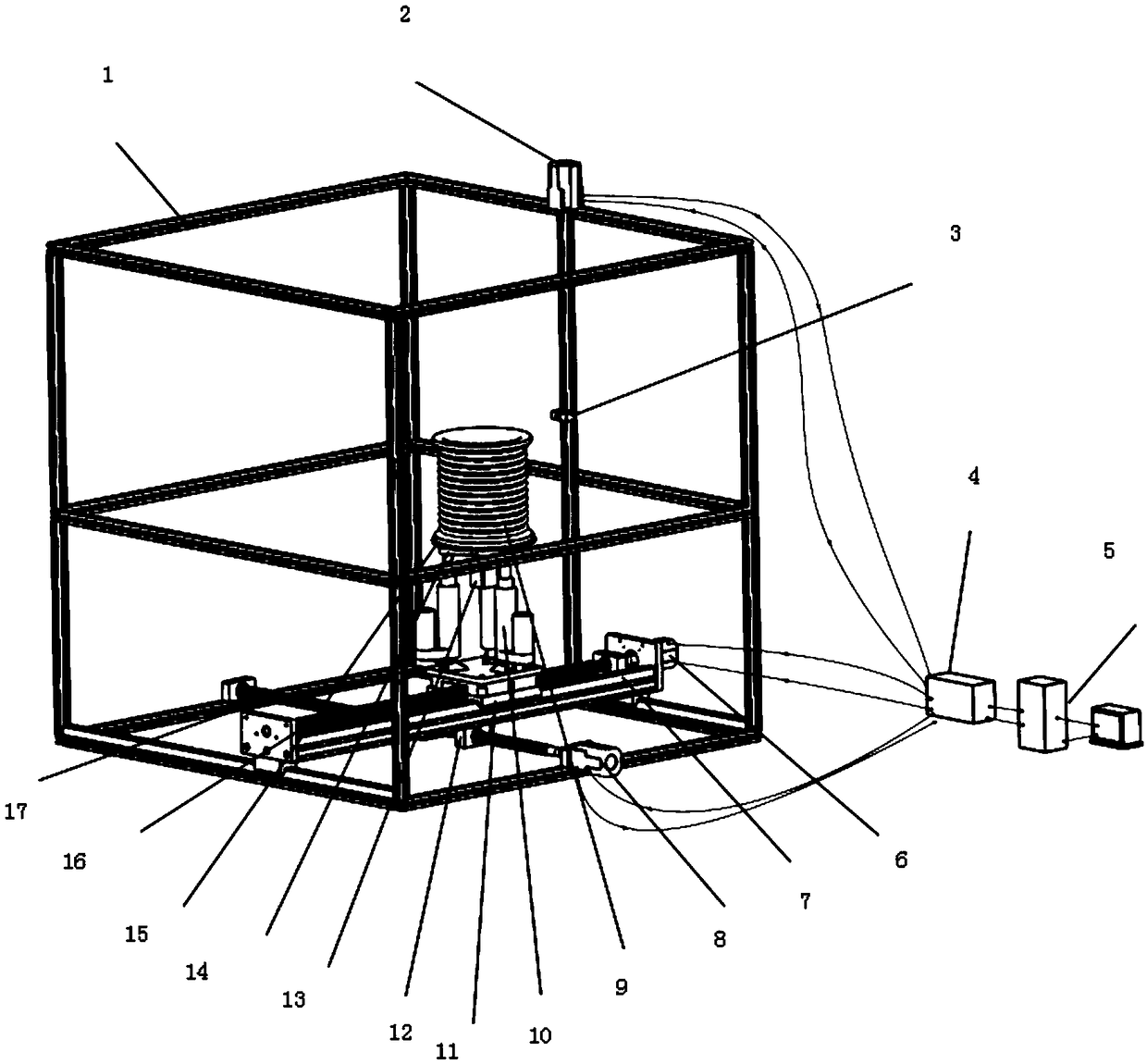

[0023] The invention provides a laser sensor displacement detection device and method for azimuth adjustment of bellows expansion joints. The structure of the device is as figure 1 shown.

[0024] Method of the present invention comprises the steps:

[0025] Step 1: Build a laser ranging sensor bellows expansion joint azimuth adjustment detection device

[0026] like figure 1 As shown, an industrial robot 2 is installed on the outside of the aluminum profile frame 1, and a laser ranging sensor 3 is installed on the industrial robot. The power and data lines of the industrial robot and the laser ranging sensor are connected to the industrial computer 4 and the computer 5.

[0027] The first stepper motor 6, the first screw mandrel 16 and the first guide rail 7 are installed on the lower side of the aluminum profile frame, and the second stepper motor 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com