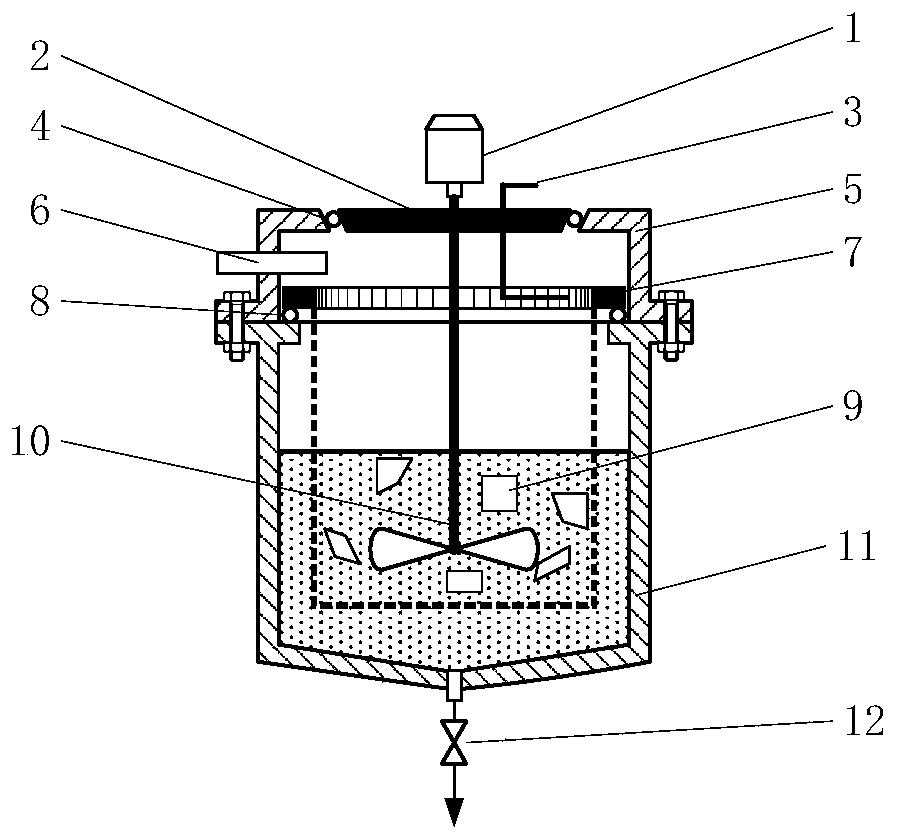

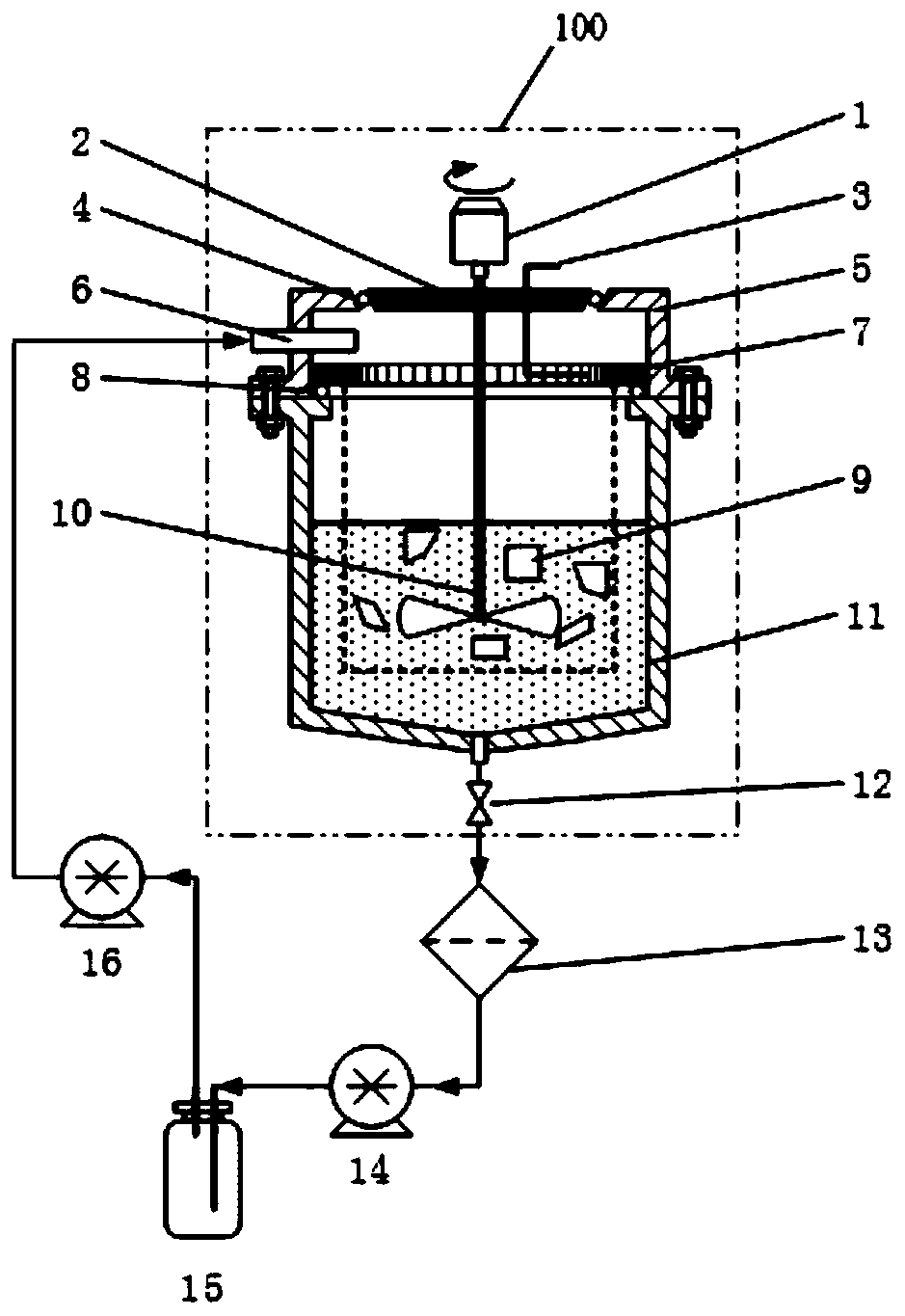

Filter material sample gamma measurement source preparation method and device based on particulate matter extraction

An extraction device and particulate matter technology, which is applied in the field of gamma measurement of filter material samples based on particulate matter extraction, can solve the problems of low separation efficiency, lack of implementation details, and large loss of particulate matter, and achieve the effect of high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

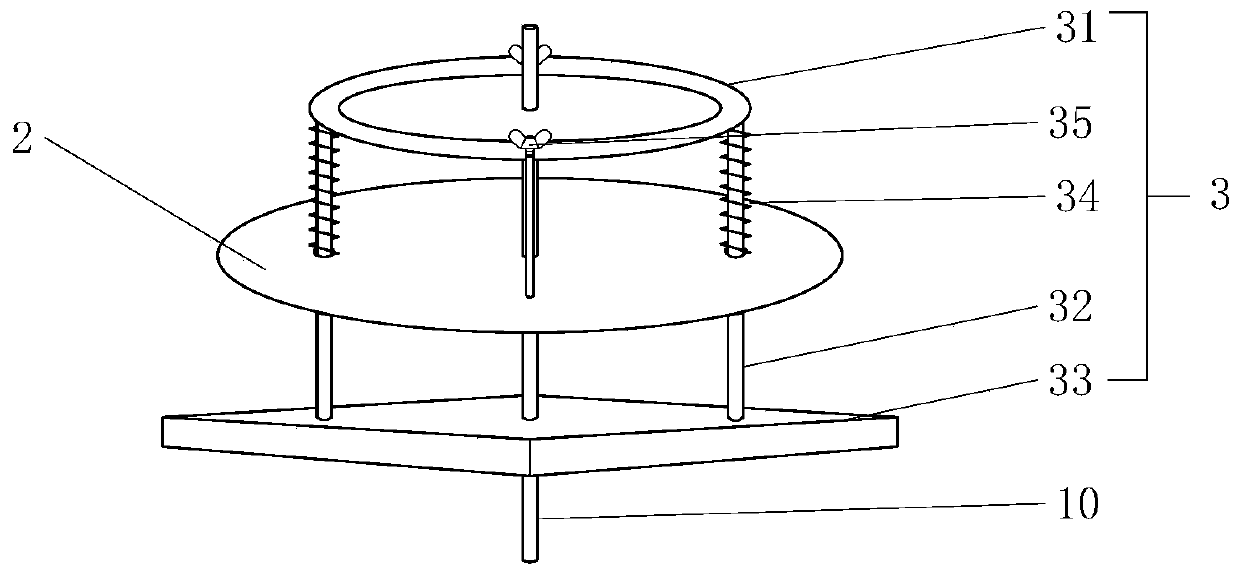

[0129] Embodiment 1: the filter material sheet 9 after sampling in step 1 is 25 grams, adds 3 liters of water, adds surfactant 1.5 milliliters; The stirring speed of step 2 is 800 revolutions per minute, and the stirring time is 3 minutes; The rotating speed of step 3 The speed is 1600 revolutions per minute, and the dehydration time is 1 minute.

Embodiment 2

[0130] Embodiment 2: the filter material sheet 9 after sampling in step 1 is 40 grams, adds 3 liters of water, adds 3 milliliters of surfactants; The stirring speed of step 2 is 400 revolutions per minute, and the stirring time is 5 minutes; The rotating speed of step 3 1400 revolutions per minute, dehydration time is 1 minute.

[0131] After measurement, the measurement results of the above-mentioned embodiment 1 and embodiment 2 are consistent with the measurement results obtained by other methods.

[0132] The method and device for manufacturing gamma measurement sources of filter material samples based on particulate matter extraction of the present invention can be widely used in the preparation of gamma measurement sources for aerosol filter material samples in different environments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com