AG (anti-glare) film and application thereof

A technology of anti-glare film and weighing scale, which is applied in the direction of coating, reflection/signal coating, etc., can solve the problems of high cost and achieve the effect of reducing reflection and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

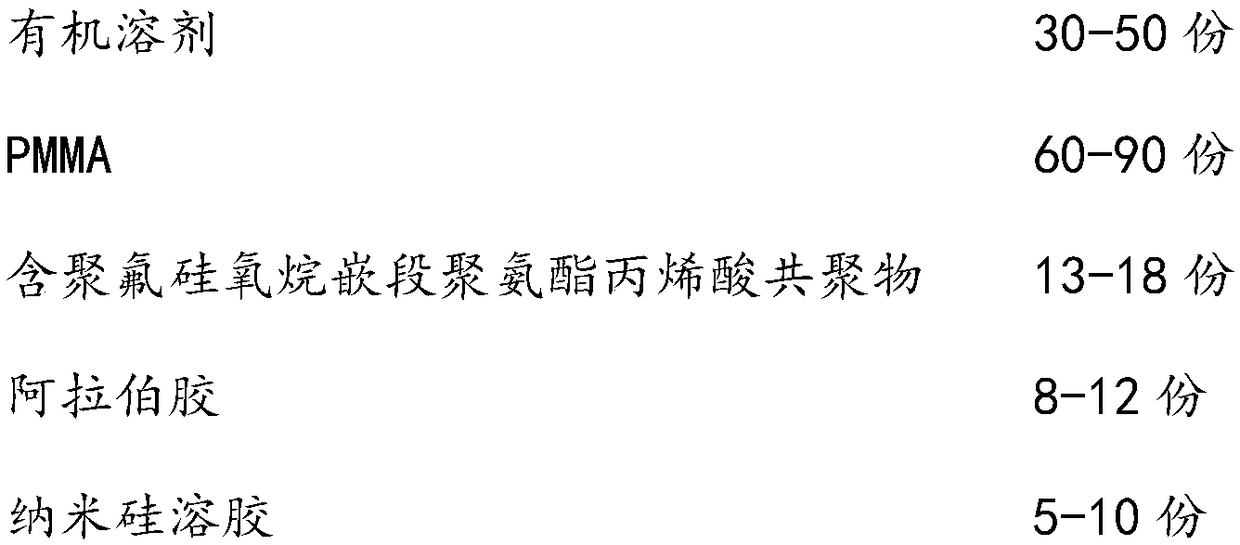

[0037] An AG anti-glare film, mainly including the following components: organic solvent, PMMA, polyurethane acrylic acid copolymer containing polyfluorosiloxane block, gum arabic, nano silica sol, lithium silicate / sodium silicate / potassium silicate, Heat stabilizer, light stabilizer, antioxidant, leveling agent, anti-blocking agent, water retention agent.

[0038] The composition of each substance in embodiment 1-embodiment 5 is the same, but the content of each substance is different, as shown in the following table 1 for details;

[0039] Table 1:

[0040]

[0041]

[0042] Among them, the organic solvent can be mixed with tetrachloroethane, phenol, acetone, and purified water, and the ratio between tetrachloroethane, phenol, acetone, and purified water is 3:1:5:0.5.

[0043] Organic solvent, PMMA, polyurethane acrylic copolymer containing polyfluorosiloxane block, gum arabic, nano silica sol, lithium silicate / sodium silicate / potassium silicate, light stabilizer, ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com