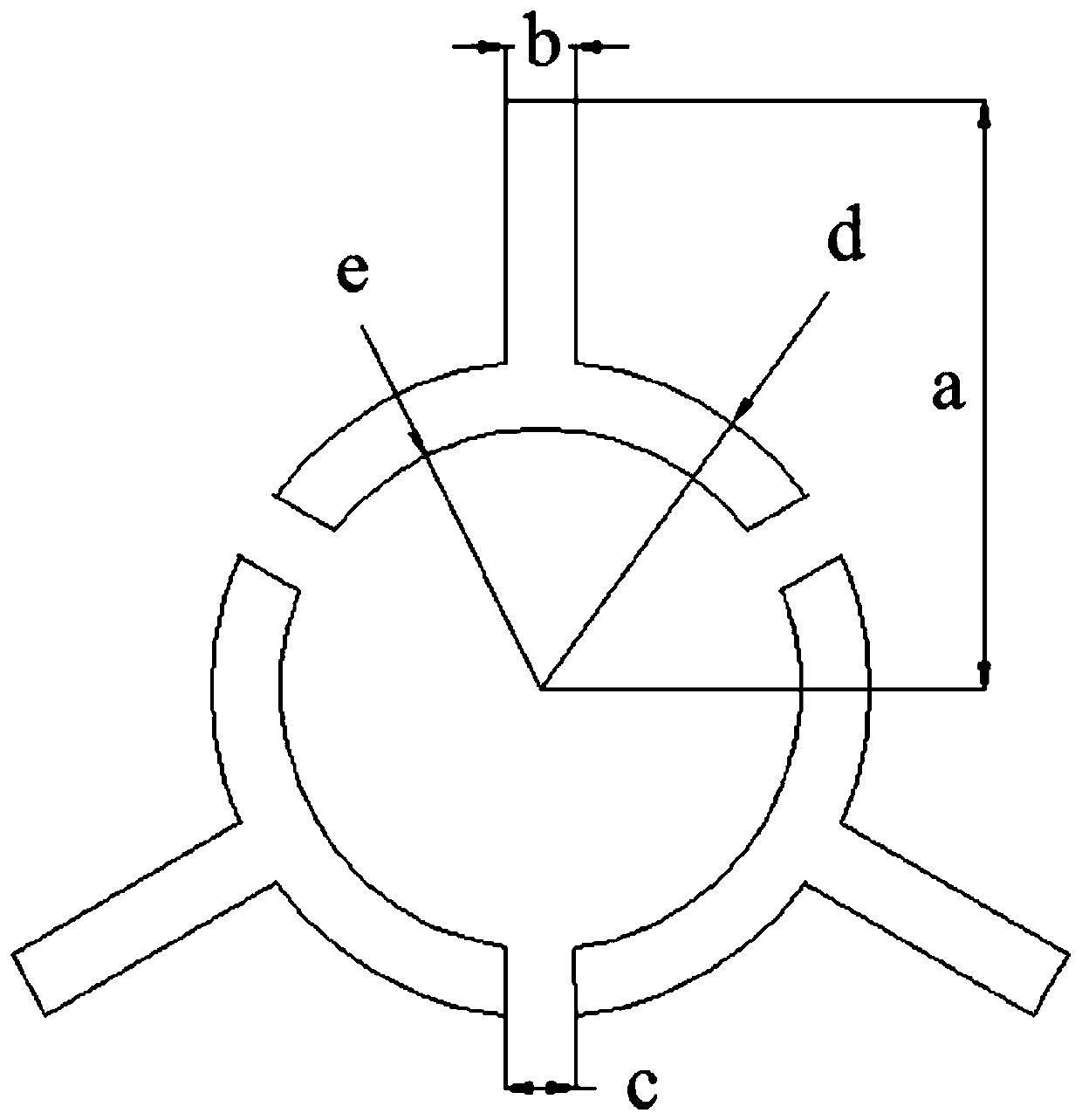

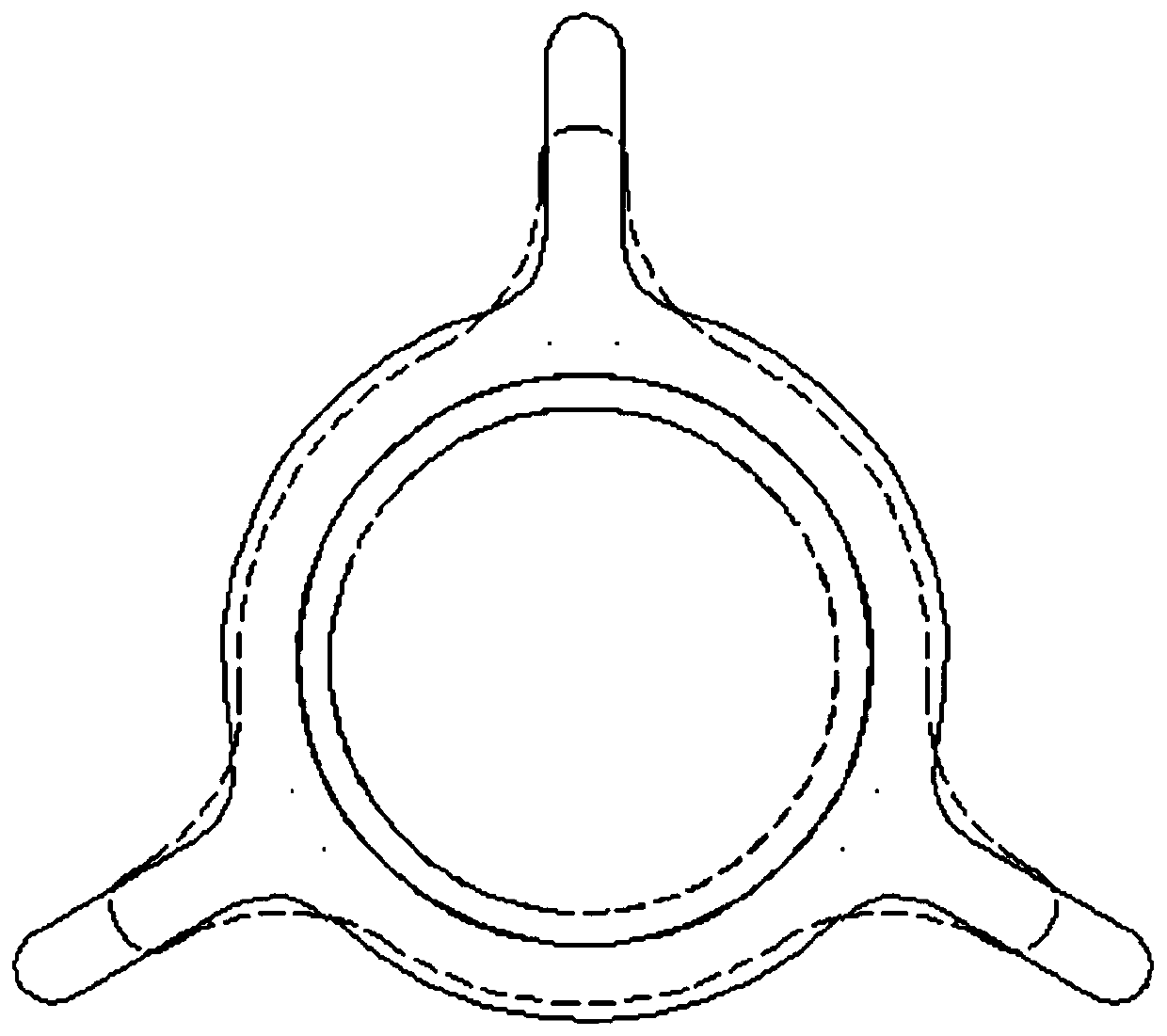

A kind of multi-leaf hollow polyester fiber fdy yarn and preparation method thereof

A polyester fiber, hollow shape technology, applied in the field of polyester spinning, can solve the problems of reducing surface tension, weakening extrusion swelling effect, poor shape retention effect of special-shaped fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of trilobal hollow polyester fiber FDY yarn. Firstly, a spinning melt is prepared, and the steps are as follows:

[0052] (1) Esterification reaction to obtain dibasic acid glycol ester;

[0053] Prepare a slurry of terephthalic acid, ethylene glycol and 2,6-naphthalenedicarboxylic acid. The molar ratio of terephthalic acid, ethylene glycol and 2,6-naphthalenedicarboxylic acid is 1:1.2:0.02. After the antimony, triphenyl phosphate and aluminum stearate are evenly mixed, the esterification reaction is carried out. The addition amount of antimony trioxide is 0.01% by weight of terephthalic acid, and the addition amount of triphenyl phosphate is 0.01% by weight of terephthalic acid. %, the esterification reaction is pressurized in a nitrogen atmosphere, the pressurization pressure is 0.1MPa, the temperature of the esterification reaction is 250°C, and the esterification reaction is when the amount of water distilled in the esterification reaction reaches 90...

Embodiment 2

[0069] A preparation method of trilobal hollow polyester fiber FDY yarn. Firstly, a spinning melt is prepared, and the steps are as follows:

[0070] (1) Esterification reaction to obtain dibasic acid glycol ester;

[0071] Mix terephthalic acid, ethylene glycol and 4,4-diphthalic acid into a slurry, the molar ratio of terephthalic acid, ethylene glycol and 4,4-diphthalic acid is 1:1.8:0.046, add acetic acid After the antimony, trimethyl phosphite and zinc stearate are evenly mixed, the esterification reaction is carried out. The addition amount of antimony acetate is 0.045% by weight of terephthalic acid, and the addition amount of trimethyl phosphite is 0.045 by weight of terephthalic acid. %, the esterification reaction is reacted under pressure in a nitrogen atmosphere, the pressure is 0.24MPa, the temperature of the esterification reaction is 258℃, and the esterification reaction is when the amount of water distilled out of the esterification reaction reaches 93% of the theore...

Embodiment 3

[0091] A preparation method of trilobal hollow polyester fiber FDY yarn. Firstly, a spinning melt is prepared, and the steps are as follows:

[0092] (1) Esterification reaction to obtain dibasic acid glycol ester;

[0093] The terephthalic acid, ethylene glycol, and bisphenol A diterephthalate are prepared into a slurry, and the molar ratio of terephthalic acid, ethylene glycol and bisphenol A diterephthalate is 1: 1.3:0.025, after adding antimony trioxide, triphenyl phosphate and aluminum stearate and mixing uniformly, carry out esterification reaction. The addition amount of antimony trioxide is 0.015% of the weight of terephthalic acid, and the addition amount of triphenyl phosphate It is 0.015% of the weight of terephthalic acid. The esterification reaction is pressurized in a nitrogen atmosphere. The pressurization pressure is 0.12MPa. The temperature of the esterification reaction is 251℃. When the amount of water distilled in the esterification reaction reaches the theoreti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com