Wide steel band for band saw and manufacturing method thereof

A manufacturing method and wide-width steel technology, applied in the field of wide-width steel strips for band saws and its manufacture, can solve the problems of poor thickness accuracy, insufficient spheroidization rate, and insufficient hardenability, etc., and achieve high straightness , high slitting precision and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

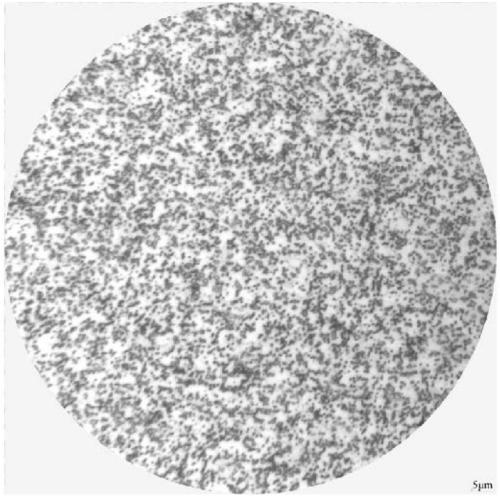

Image

Examples

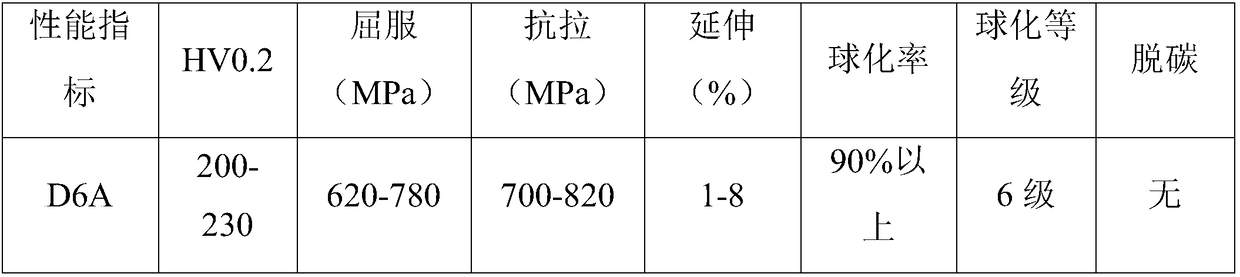

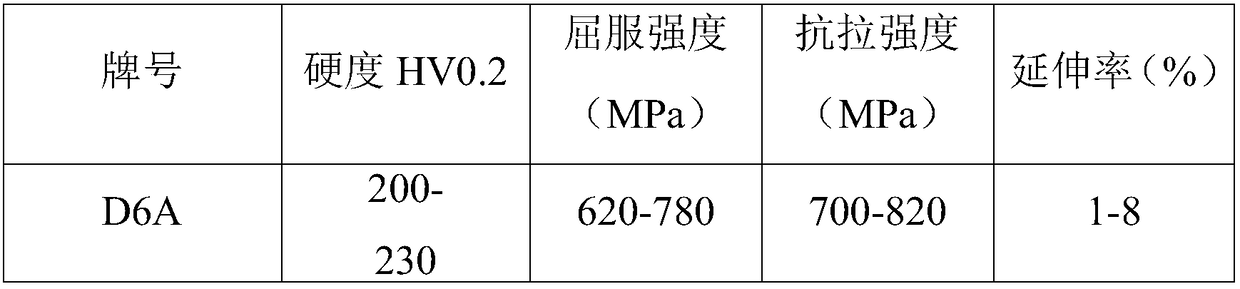

Embodiment 1

[0046] Embodiment 1 (D6A):

[0047] (1) Hot rolling:

[0048] The composition of hot-rolled raw materials is shown in the table below:

[0049]

[0050] The balance is Fe and trace unavoidable impurities;

[0051] The finishing temperature of hot rolling is 890±20℃, and the coiling temperature of finishing rolling is 600±20℃;

[0052] (2) pickling

[0053] The hot-rolled steel coils are pickled by a push-pull shallow-trough turbulent-flow pickling unit, using hydrochloric acid pickling, the concentration is controlled between 7% and 17% (w / w), and the surface oxide scale is removed.

[0054] (3) Pre-spheroidizing annealing

[0055] The annealing adopts a full-hydrogen bell-type furnace, and annealing is carried out according to the following setting process:

[0056] Annealing process control parameter name

Various parameter control values

steel type

D6A

Thickness (mm)

2.7

Width (mm)

330

Loading capacity (T)

80~9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com