Preparation method of far infrared heating bandage

A far-infrared heating and bandage technology, applied in bandages, medical science, absorbent pads, etc., can solve the problems of single function, unable to meet the higher requirements of the medical effect of bandages, unable to ensure the temperature stability around the wound epidermis, etc., to promote blood circulation. Circulation, excellent infrared radiation performance, the effect of accelerating wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

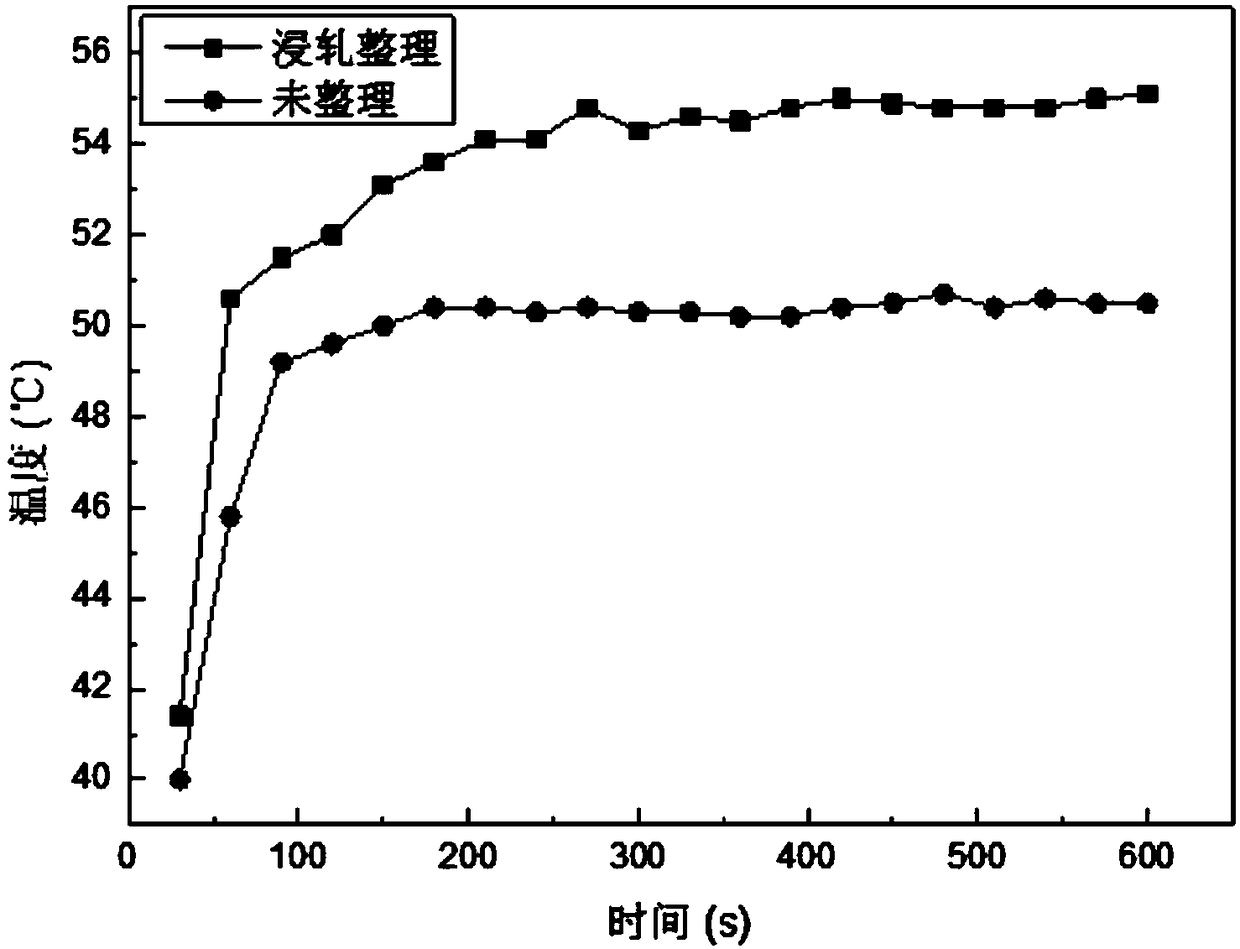

[0029] A 10cm×10cm polyester bandage (180 threads / 10cm in warp density and 140 threads / 10cm in weft density) was washed with 3% non-ionic detergent Sandoclean PC at 30°C for 30 minutes, and dried at room temperature.

[0030] Mix tourmaline powder and deionized water, the mass fraction of tourmaline is 10%, stir at room temperature for 5 minutes; then add carboxymethylcellulose sodium dispersant, the mass fraction of dispersant is 1%, stir at high speed for 1 hour, you can get tourmaline dispersion;

[0031] Add the tourmaline dispersion prepared in the second step into the mixture of polyacrylate (model E0503) and deionized water, the mass fraction of the tourmaline dispersion is 50%, the mass fraction of polyacrylate is 15%, and stir at a high speed for 2 Hours, the tourmaline post-finishing solution is prepared;

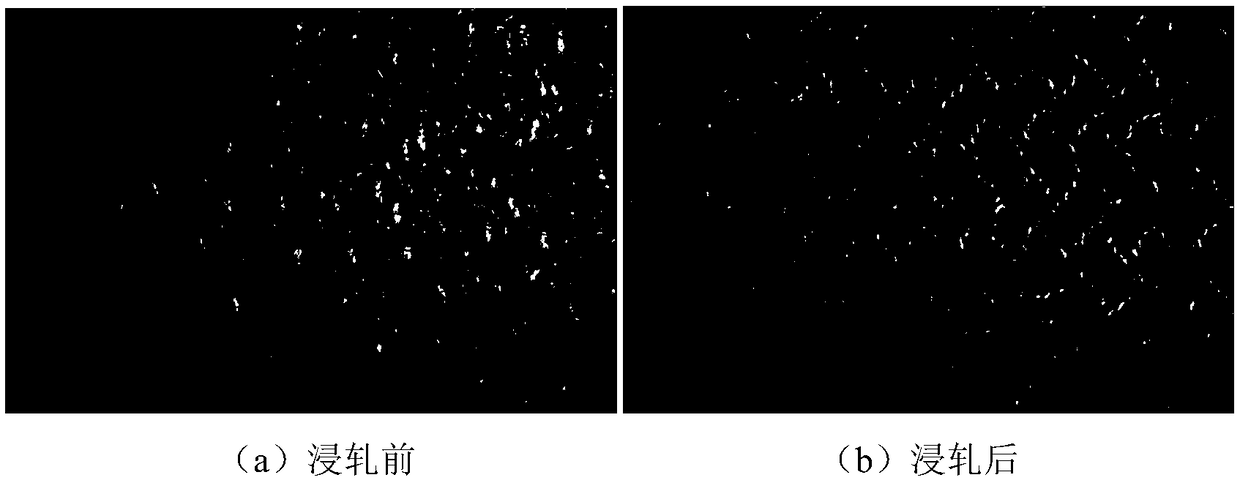

[0032] The bandage washed and dried in the first step is soaked and rolled in the finishing solution, the excess rate is 60%, dried at 80°C for 5 minutes, and th...

Embodiment 2

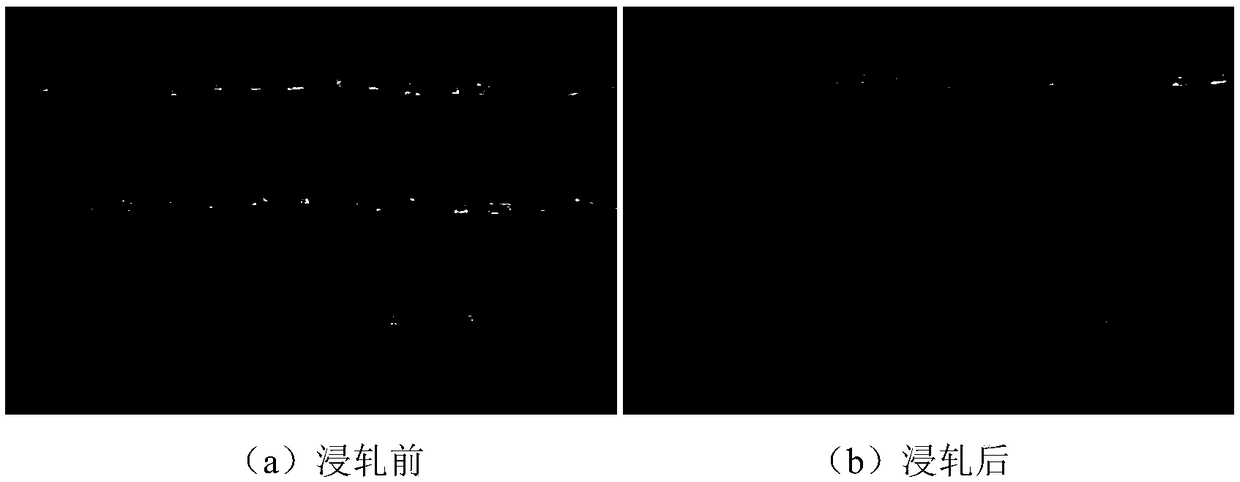

[0035] With 10cm * 10cm polypropylene nonwoven bandage (square meter gram weight 95.15g / m 2 ) was washed with 3% non-ionic detergent Sandoclean PC at 20°C for 40 minutes, and dried at room temperature.

[0036] Mix tourmaline powder and deionized water, the mass fraction of tourmaline powder is 10%, stir at room temperature for 10 minutes; add carboxymethyl cellulose sodium dispersant, the mass fraction of carboxymethyl cellulose sodium is 1%, stir at high speed 2 hours, made tourmaline dispersion;

[0037] The tourmaline dispersion prepared in the second step is added to the mixture of polyacrylate (model E0503) and deionized water, the tourmaline dispersion accounts for 70% of the mixture mass fraction, and the polyacrylate mass fraction is 20%, Stir at high speed for 3 hours to prepare tourmaline finishing solution;

[0038] The bandage washed and dried in the first step is dipped and rolled in the finishing solution, with a rolling rate of 60%, dried at 100°C for 3 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com