Associated gas treatment plant section plug-flow collecting system and method

A slug flow and associated gas technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of large overall volume of capture equipment, difficult equipment installation/transportation, and poor adaptability in the later stage. Small footprint, quick installation and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

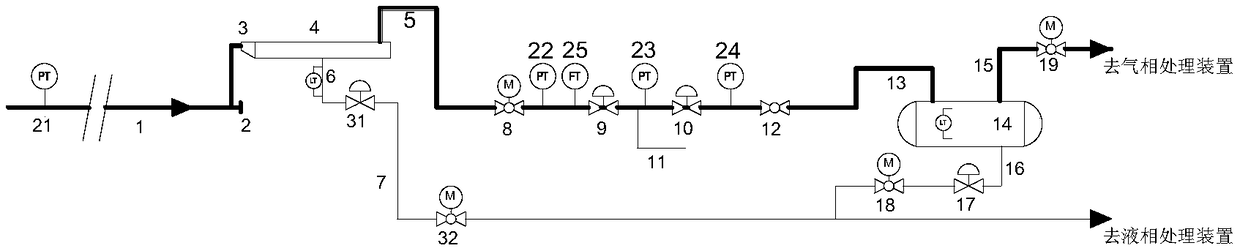

[0026] A slug capture system for an associated gas treatment plant, including a pressure-flow detection system, a gas-liquid-solid separation pipeline system, a double-regulating valve pressure compensation system, a gas-liquid separator, and the like.

[0027] A slug capture system for an associated gas treatment plant, such as figure 1 As shown, it mainly includes: inlet pipe section 1, turning tee 2, expanded diameter eccentric large and small joints 3, expanded diameter horizontal straight pipe 4, gas phase riser 5, liquid level control pipe 6, liquid phase pipe 7, liquid level adjustment Valve 31, electric ball valve 32, electric ball valve 8, 1# regulating valve 9, 2# regulating valve 10, release pipeline 11, manual ball valve 12, separator inlet pipe 13, gas-liquid separator 14, gas phase outlet pipe 15, Liquid phase outlet pipeline 16, liquid phase regulating valve 17, liquid phase outlet ball valve 18, gas phase outlet ball valve 19, upstream pressure transmitter 21, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com