A Method of Dynamically Controlling Separator Pressure to Suppress Severe Slug Flow

A dynamic control and separator technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as oil and gas production reduction, dead well accidents, etc., to increase oil and gas production, eliminate harmful flow patterns, and stabilize Effect of standpipe differential pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for dynamically controlling separator pressure to suppress severe slug flow according to the present invention will be described in detail below with reference to the accompanying drawings.

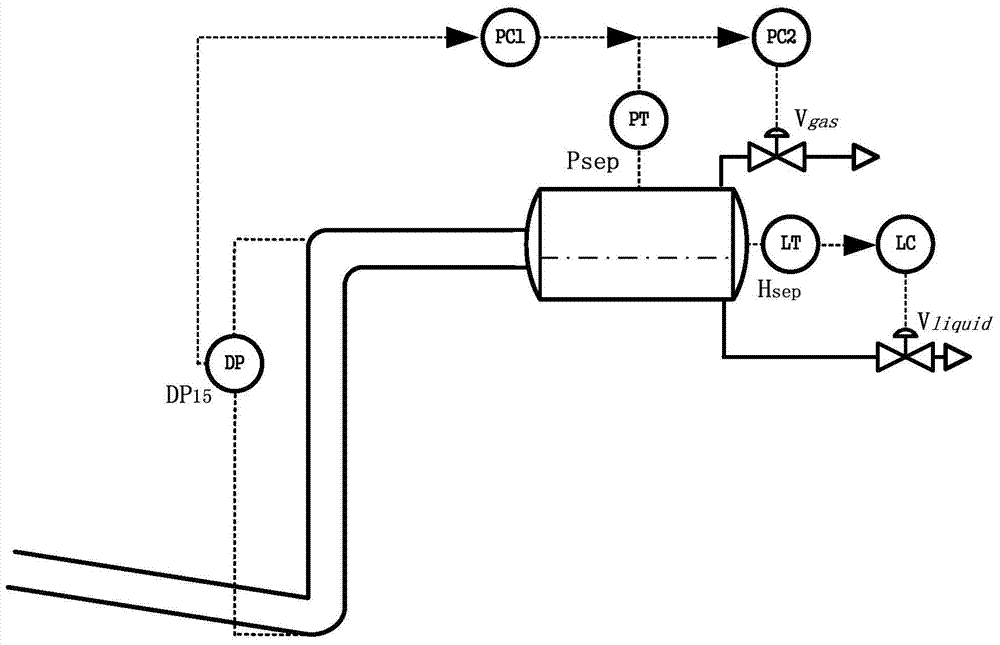

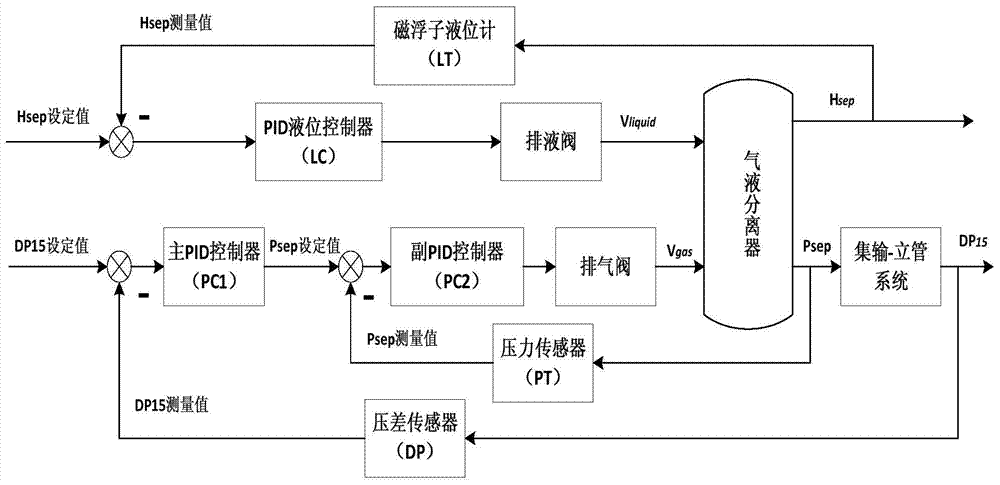

[0038] see figure 1 The structure diagram of the gathering-riser piping system shown and figure 2 The control flow chart is shown. For single-loop PID liquid level control, the controlled variable is the gas-liquid separator liquid level H sep , the control variable is the opening of the drain valve at the bottom of the gas-liquid separator V liquid , the actual liquid level of the separator measured by the magnetic float level gauge LT and H sep The set value is compared, and the difference obtained is PID logic operation through the PID liquid level controller LC, and the corresponding discharge valve opening is calculated to control the speed at which the liquid in the gas-liquid separator flows out through the discharge valve to stabilize the liquid level. ; For c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com