Airflow-thermo-mechanical coupling excitation test device

A heat-mechanical coupling and test device technology, which is applied in measuring devices, machine/structural component testing, vibration testing, etc., can solve the problems of difficulty in building a seal on the end face of the rotating turntable, insufficient excitation force, airflow loss, etc., to avoid air intake The effects of deficiencies, improved efficiency, and smooth gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the patent is not limited to the structures in the illustrations, and is within the scope of protection of the patent.

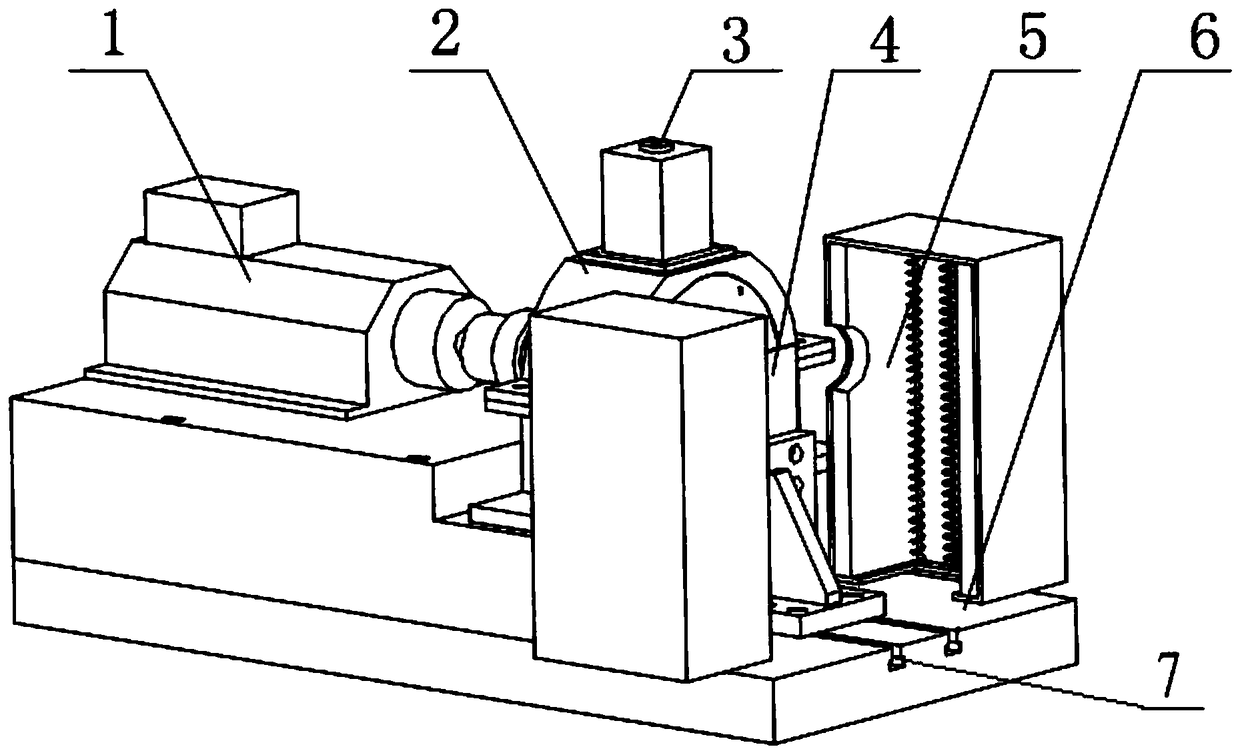

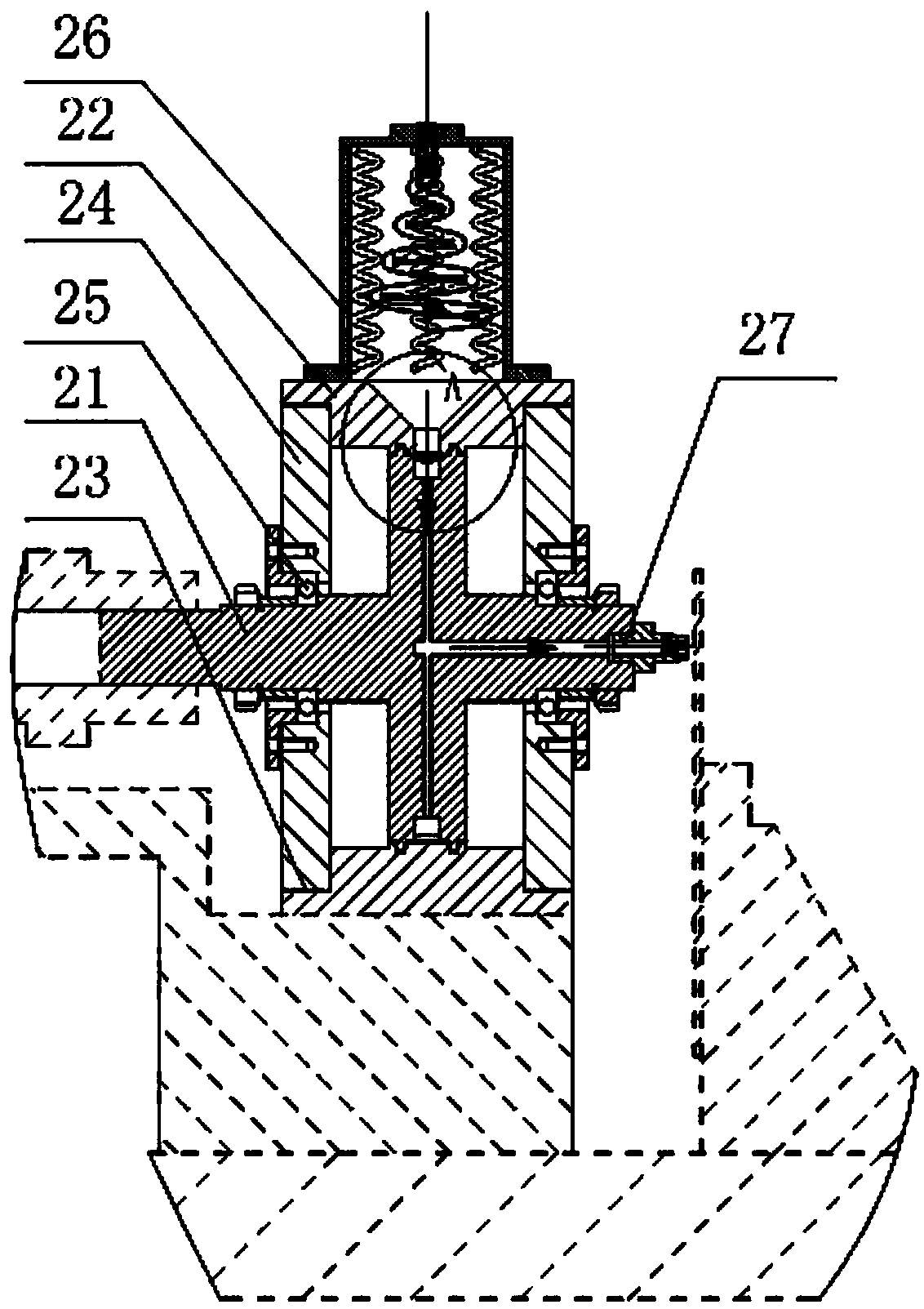

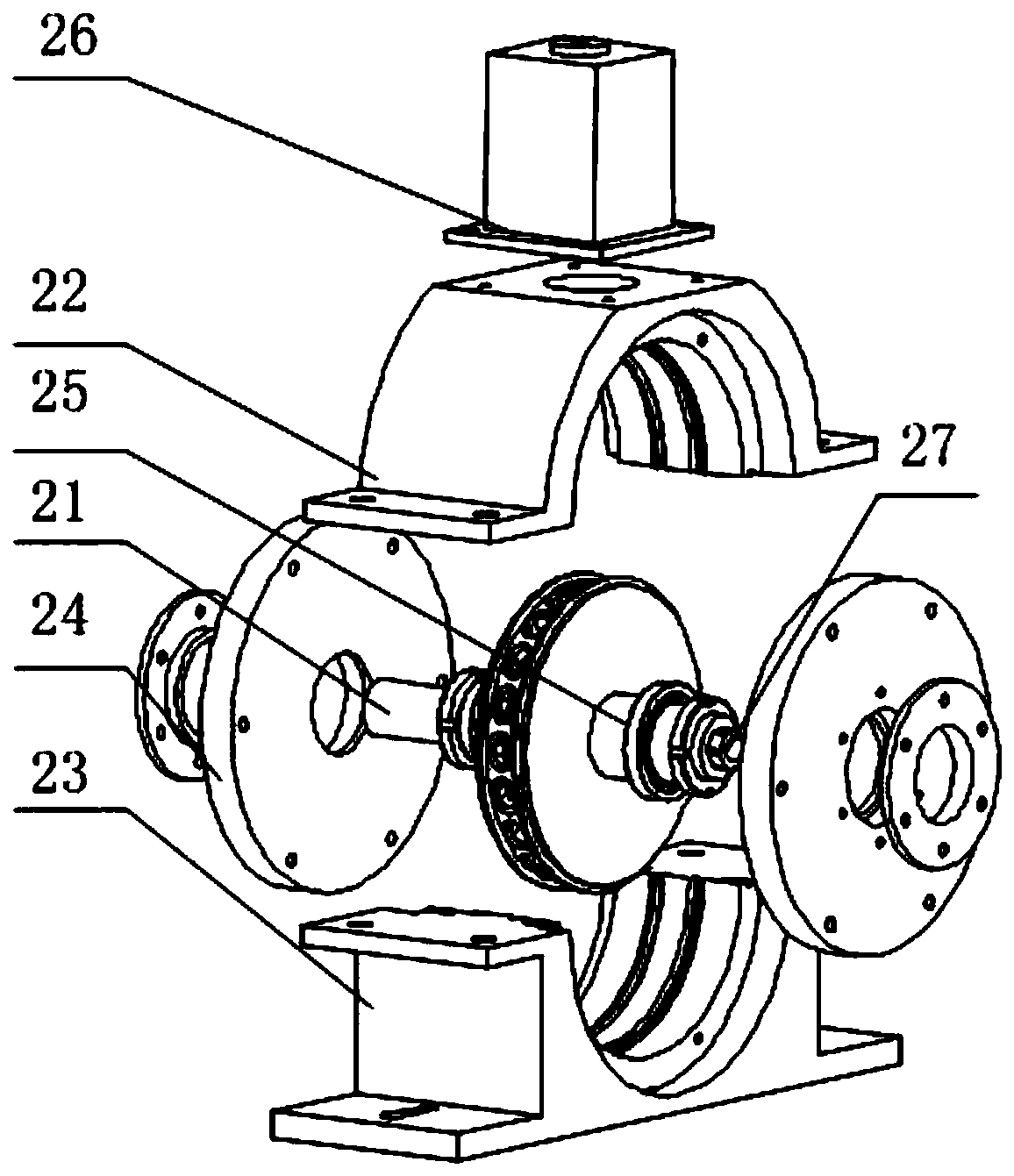

[0031] Such as figure 1As shown, the airflow-heat-mechanical coupling excitation test device of the present invention consists of a drive system 1, a rotating alternating airflow generating device 2, an airflow heating device 3, a test piece and its fixture system 4, a test piece heating device 5 and a base 6 The driving system 1 is composed of a driving motor and a coupling, and the two are fixedly connected, wherein the driving motor is a variable frequency motor or a servo motor, and the rotating alternating air flow generator 2 is connected to the driving system 1, and rotates at a high speed within a certain speed range. High-frequency alternating airflow is generated; the airflow heating device 3 is used for heating the airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com