Device and method for testing fire resistance of welding protective mask

A protective mask and testing device technology, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems of being easily affected by the external environment, the plastic parts of the mask are easy to catch fire, and the detection data is inaccurate, etc., achieving simple structure, convenient assembly, and improved detection. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

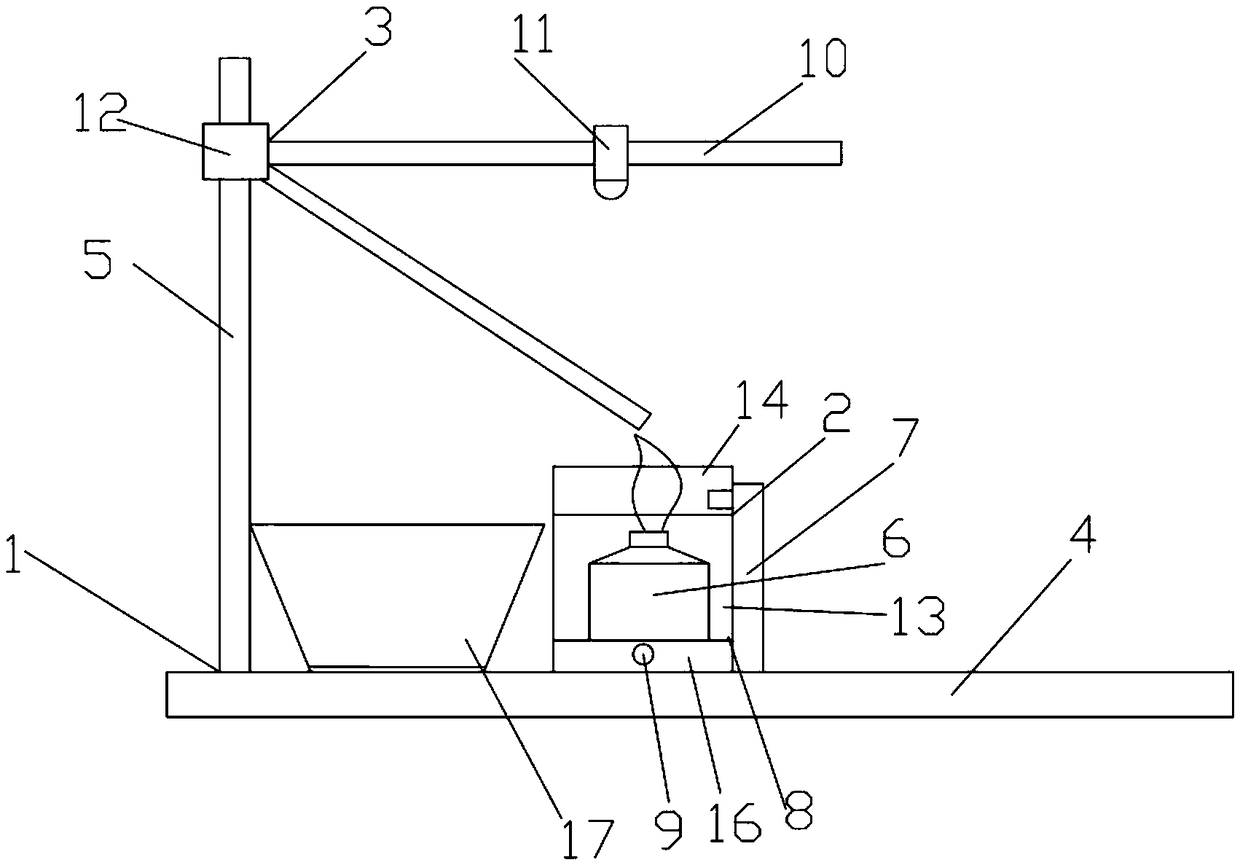

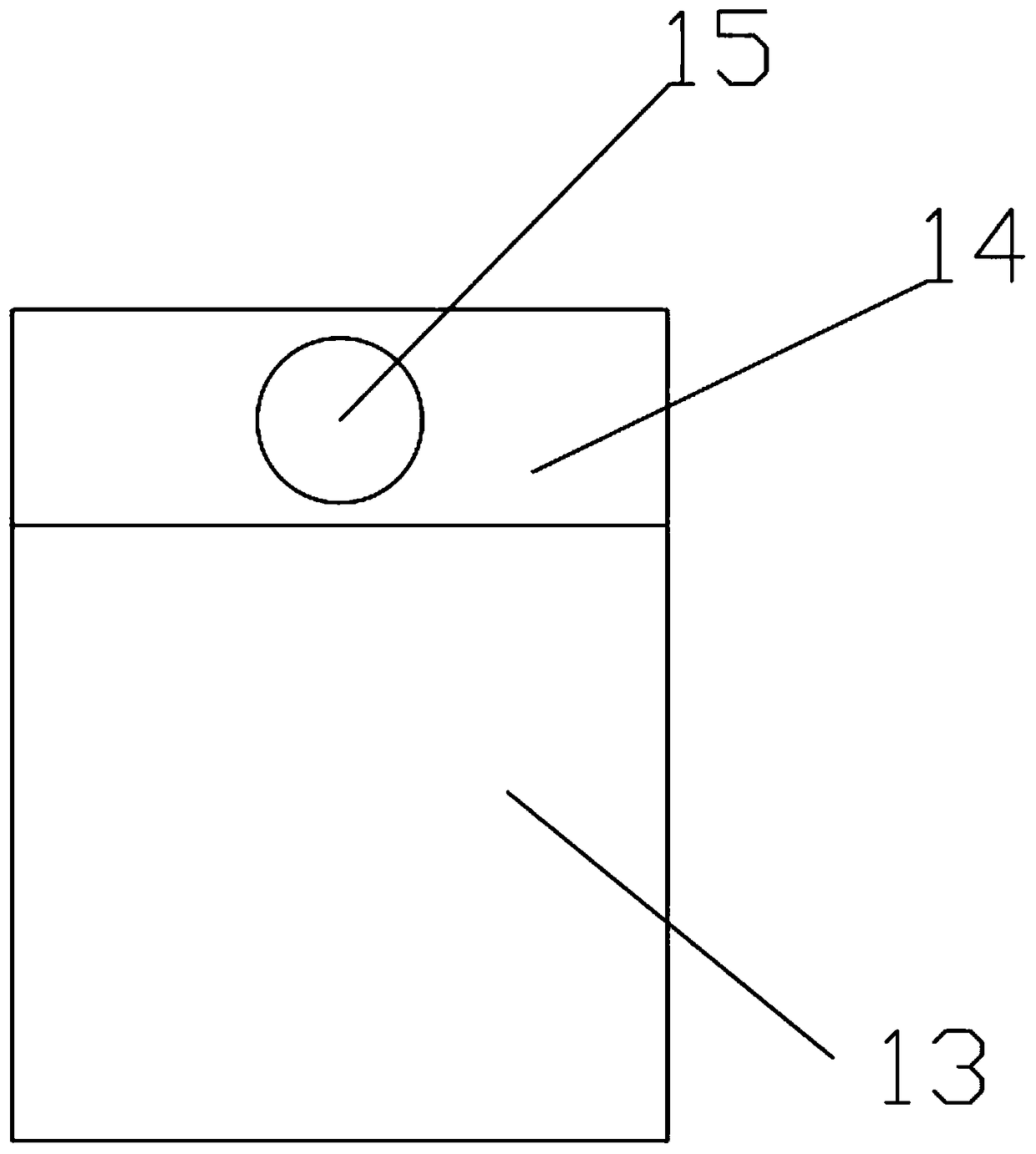

[0033] Such as Figure 1 ~ Figure 2 As shown, the technical solution adopted by the present invention to solve the above-mentioned technical problems is: a kind of flame retardancy testing device of welding protective mask, comprises combustion frame 1, is positioned at described combustion frame 1 and is provided with combustion device 2 and measuring device 3,

[0034] Described combustion frame 1 comprises combustion base 4 and combustion support frame 5, and described combustion support frame 5 is fixedly arranged on combustion base 4 in vertical shape;

[0035] The combustion device 2 includes a burner 6, an ignition device 7, a fire extinguishing device 8, a touch ignition switch 9 and a combustion mount 16, the fire extinguisher 8 is arranged on the combustion mount 16, and the burner 6 is provided with a fire extinguisher 8 Inside, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com