Far-infrared domain polarization-insensitive all-dielectric super-surface structure and manufacturing method thereof

A polarization-insensitive, fabrication method technology, applied in optical components, optics, instruments, etc., can solve the problems of lack of repeatability and flexibility, polarization sensitivity of excited electromagnetic waves, etc., and achieve ultra-high refractive index sensitivity, high abundance, and fabrication. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

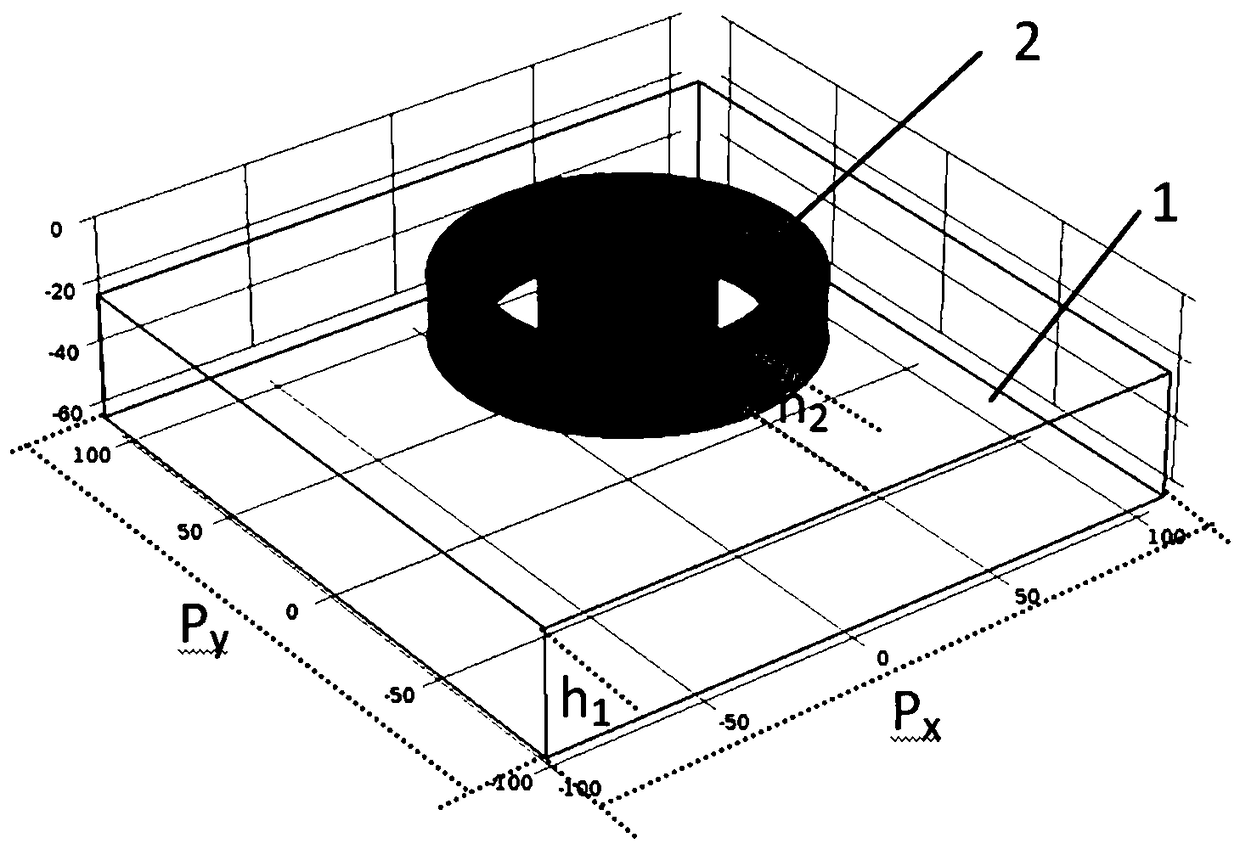

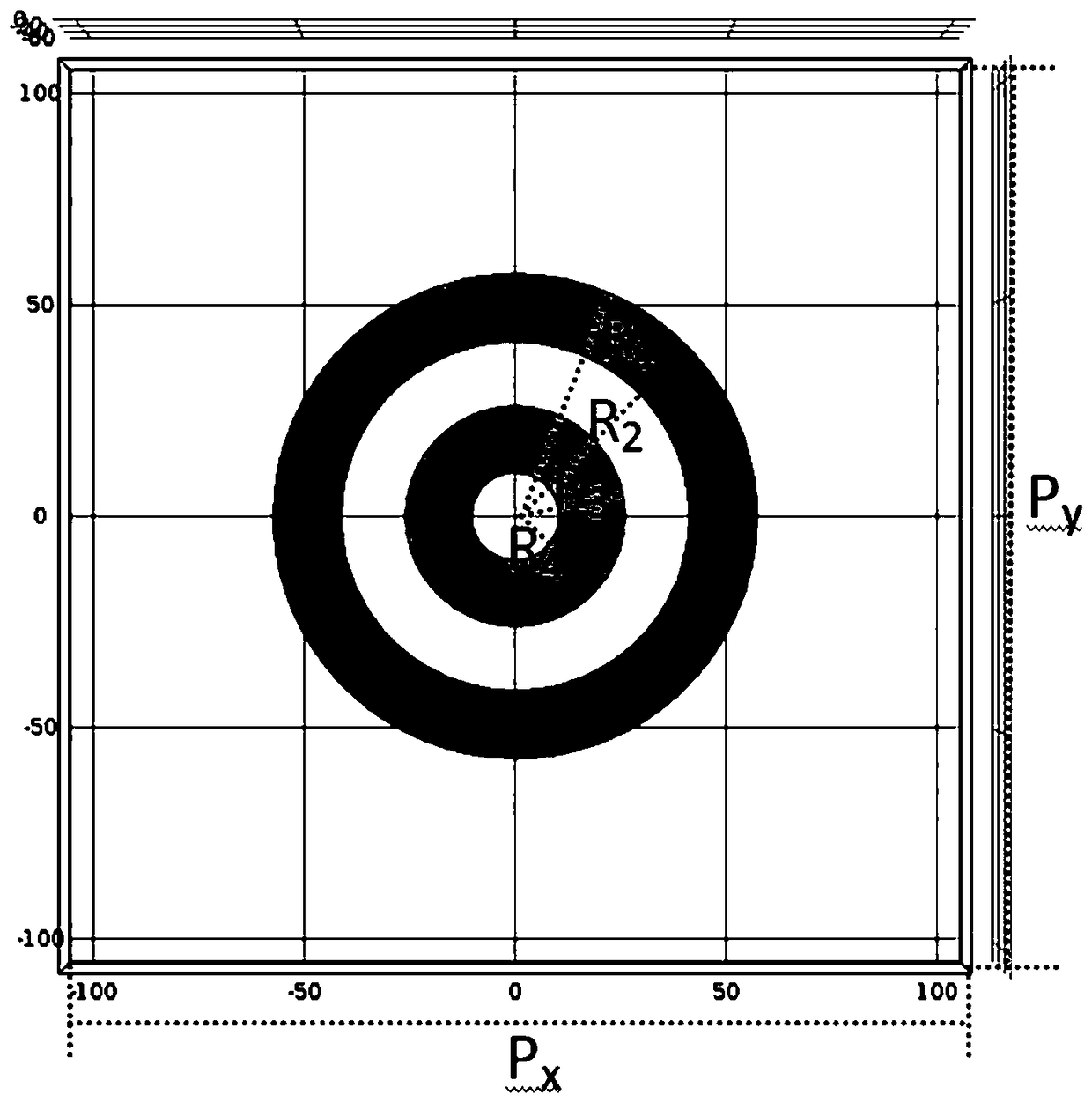

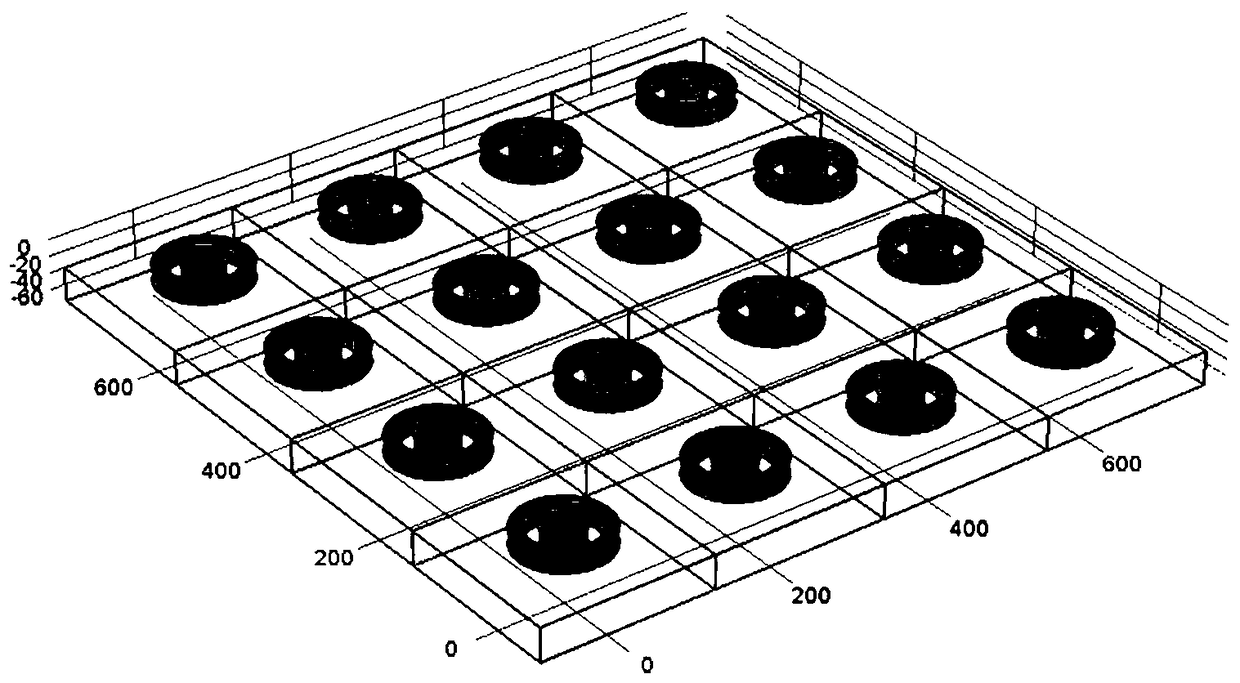

[0039] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a far-infrared domain polarization-insensitive all-dielectric metasurface structure, including a substrate 1 and a concentric double-closed dielectric resonator ring unit 2 in a two-dimensional periodic distribution on the surface of the substrate 1; the substrate 1 and the concentric double-closed dielectric resonant ring unit 2 are all dielectric materials.

[0040] Further, the refractive index of the all-dielectric material of the substrate 1 is greater than 1.4 and less than or equal to 5. Preferably, the all-dielectric material of the substrate 1 is SiO 2 .

[0041] Further, the refractive index of the all-dielectric material of the concentric double-closed dielectric resonant ring unit 2 is greater than 2 and less than or equal to 6. Preferably, the all-dielectric material of the concentric double-closed dielectric resonant ring unit 2 is Si.

[0042] SiO 2 And Si material, high abundanc...

Embodiment 2

[0055] The base material used in the concentric double-closed dielectric resonant ring unit 2 is Si, and the refractive index n=3.4; the base material used in the base 1 is SiO 2 , Refractive index n=1.48; unit period P x =P y =200μm; substrate thickness h 1 =40μm; double ring thickness h 2 =20μm; from outside to inside, the radius r of each circle 1 = 60 μm, r 2 = 45 μm, r 3 = 30 μm, r 4 =15μm, such as Figure 1 to Figure 4 shown.

[0056] The far-infrared electromagnetic wave is perpendicular to the metasurface, and the transmission spectrum in the far-infrared band (1400-1450 GHz) is calculated by the finite element method, and the modulation depth of the Fano resonance line is greater than 0.8, and the central wavelength is f 0 =1420GHz, resonance quality factor Q=f 0 / Δf=473; change the polarization direction of the incident electromagnetic wave to 15°, 30°, and 45°, except that the Fano resonance valley moves up slightly with the increase of the angle, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com