Carbon fiber copper-clad composite material and application thereof as antenna radiator

An antenna radiator and composite material technology, which is applied to carbon fiber copper clad mesh composite materials and its application field as an antenna radiator, can solve problems such as being unsuitable for antenna radiators, restricting the application of carbon fiber material antenna radiators, etc., and achieve a clear method. , Prevent oxidation and corrosion, prevent the effect of thread seizure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

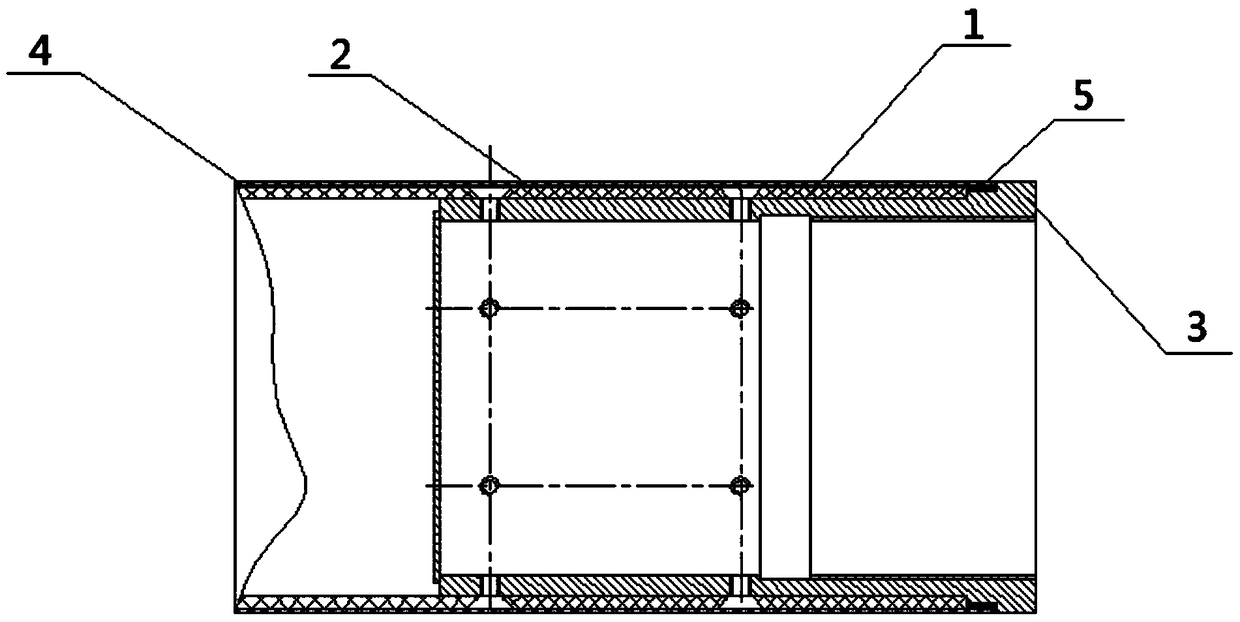

[0021] Example 1, such as figure 1 As shown, this embodiment discloses a carbon fiber copper-clad mesh composite material, which includes more than two sections of carbon fiber round tubes 1, copper mesh 2 is embedded on the surface of the carbon fiber round tubes, and the sections of carbon fiber round tubes are connected by metal joints 3 Together, the metal joint and the carbon fiber round tube are assembled together by riveting or screwing, the metal joint and the copper mesh are welded together by silver welding, and then the copper mesh and the metal joint are covered with winding epoxy. Laminated glass fiber cloth 4, epoxy laminated glass fiber cloth also covers the weld 5 between the metal joint and the copper mesh at the same time, to prevent oxidation of the weld. Finally, paint is applied to the surface of the epoxy laminated fiberglass cloth.

[0022] In this embodiment, the copper mesh is 80-mesh pure copper mesh with a thickness of 0.12 mm. From the perspective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com