Floor polishing machine

A technique for polishing machines and floors, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. It can solve the problems of difficult disassembly and cleaning, difficult disassembly and assembly of polishing wheels, and the generation of more debris, etc. problem, to achieve the effect of improving the fixing effect, improving the polishing efficiency and use effect, and having a good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

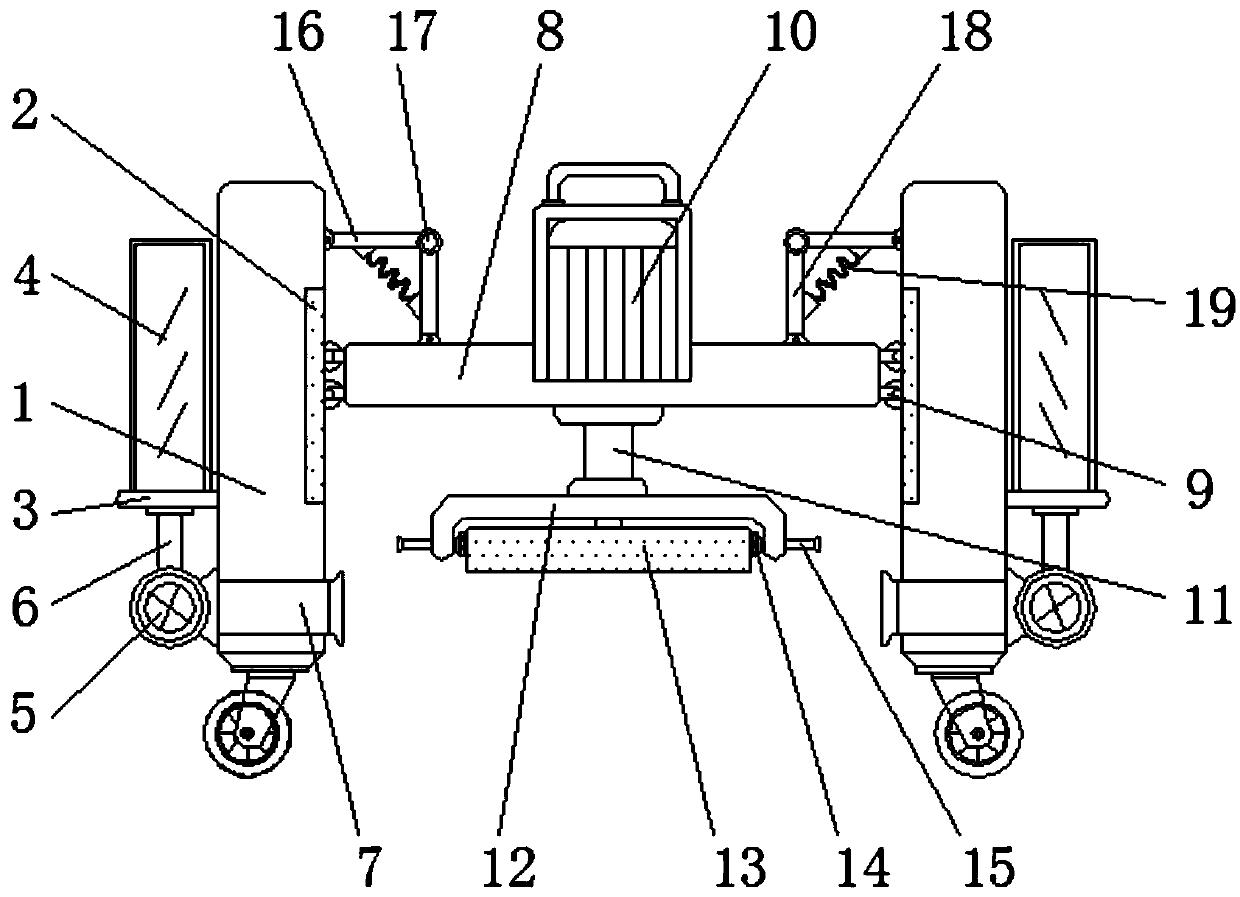

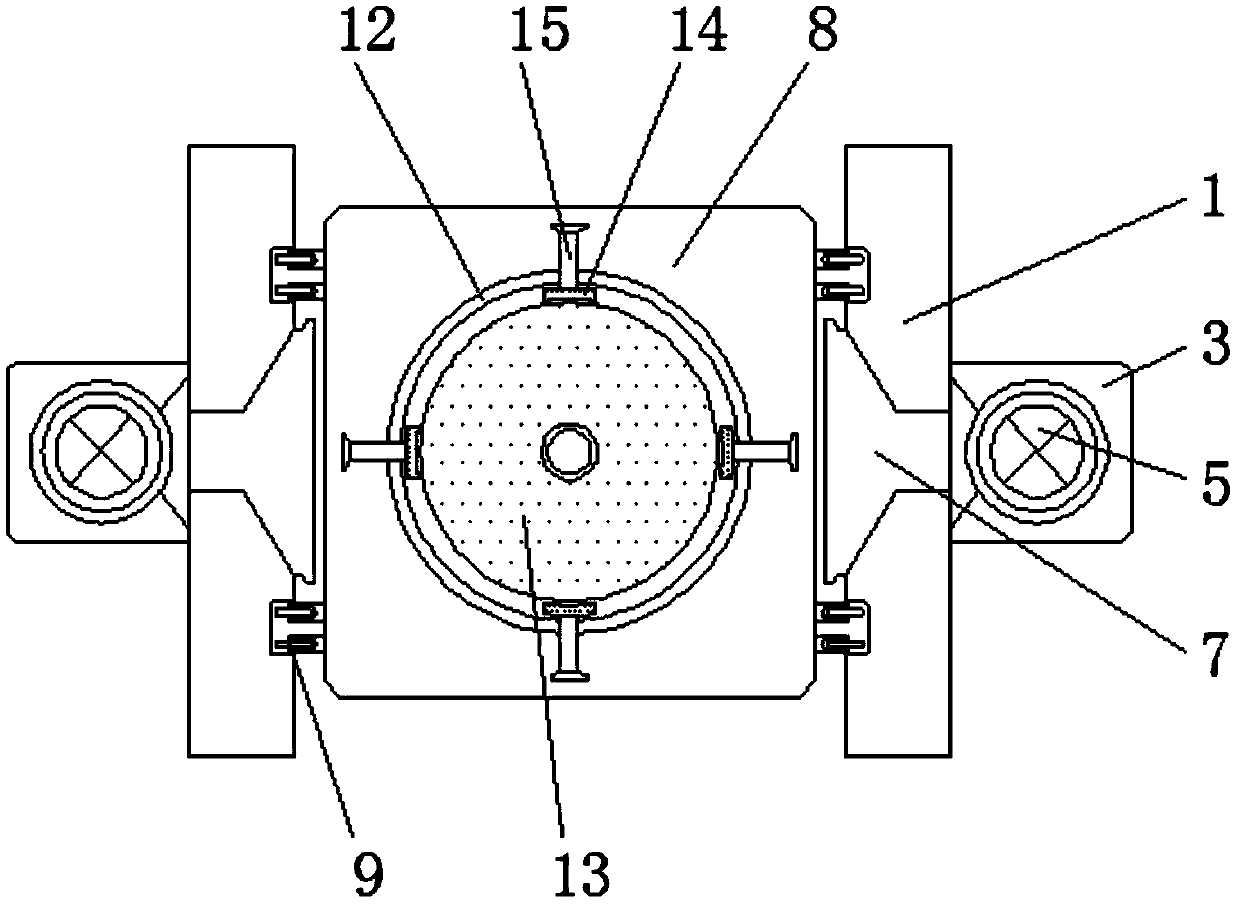

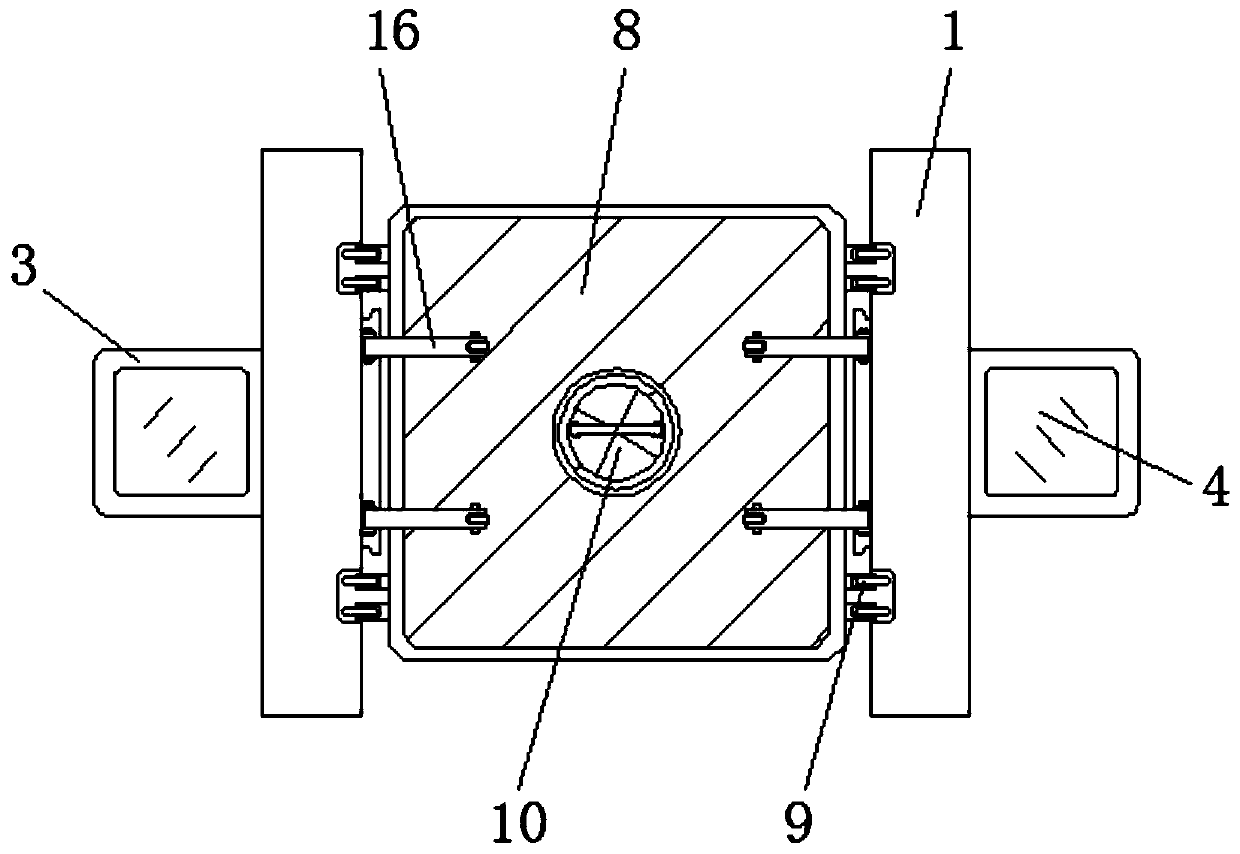

[0037] A floor polisher is a machine used to polish the floor to make the surface of the floor smooth. The polishing is mainly achieved by grinding the floor. Therefore, some debris will be generated during the polishing process. These debris will be splashed on the surrounding floor during the operation of the polishing wheel, making the floor surface dirty and difficult to clean due to the relatively small size of the debris. Also some debris can be directly adhered on the buffing wheel when producing, thereby make the buffing effect of buffing wheel get worse, so buffing wheel needs to be pulled down frequently to clean or change, to keep the buffing effect of polishing machine, but, existing Polishing machines in the art usually directly connect the polishing wheel to the output shaft of the motor, and if the polishing wheel can rotate with the motor while maintaining the direct connection between the motor and the polishing wheel, it will make it very difficult to disassem...

Embodiment 2

[0047] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that there are two threaded rods 15 in this embodiment. Compared with Embodiment 1, its structure is simpler and the cost is reduced. However, for the fixing of the polishing wheel 13 The effect is reduced. During the working process of the polishing machine, the polishing wheel 13 may partially shake, which affects the polishing effect of the polishing machine.

Embodiment 3

[0049] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that there are 6 threaded rods 15 in this embodiment. Compared with Embodiment 1, its fixing effect is better, but it will become more complicated during installation and increase Production cost and assembly time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com