Ultra-slippery antibacterial material, preparation method thereof and ultra-slippery antibacterial guide pipe

A technology of antibacterial materials and antibacterial layers, applied in the direction of coating, etc., can solve the problems of cell or tissue biotoxicity, promote bacterial drug resistance, etc., achieve the effect of reducing initial adhesion, good sterilization and antibacterial, and improving lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The present invention also provides a kind of preparation method of super slippery antibacterial material, comprises the following steps:

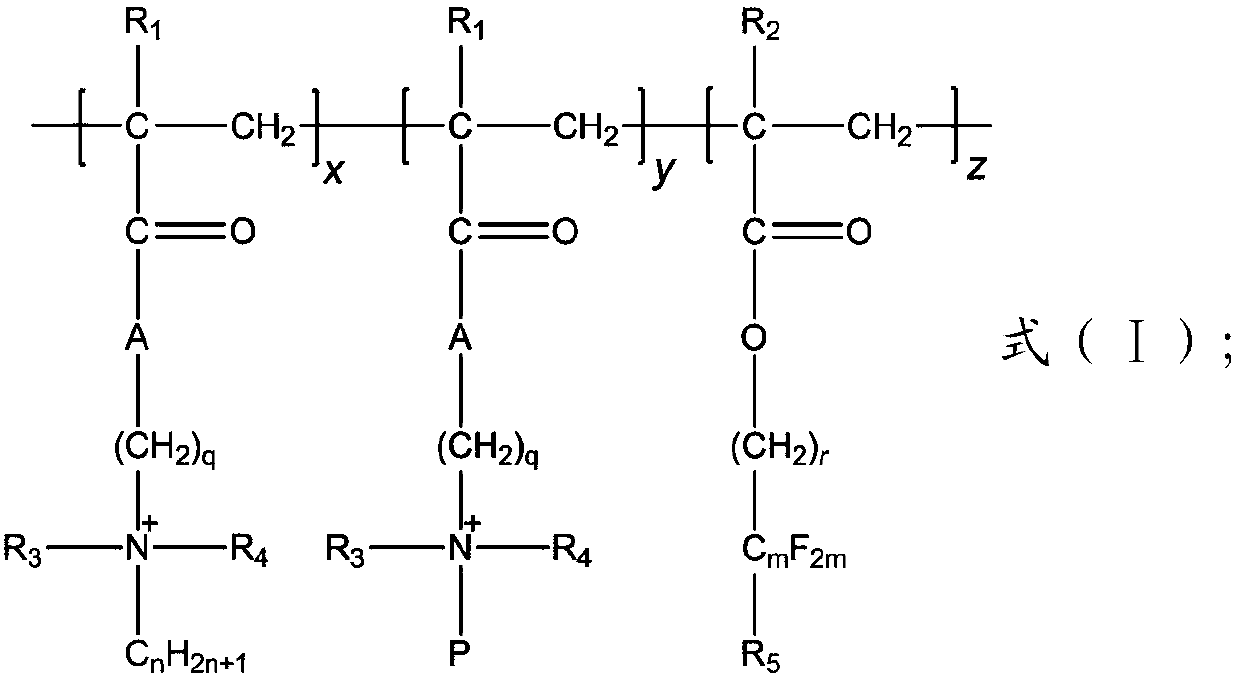

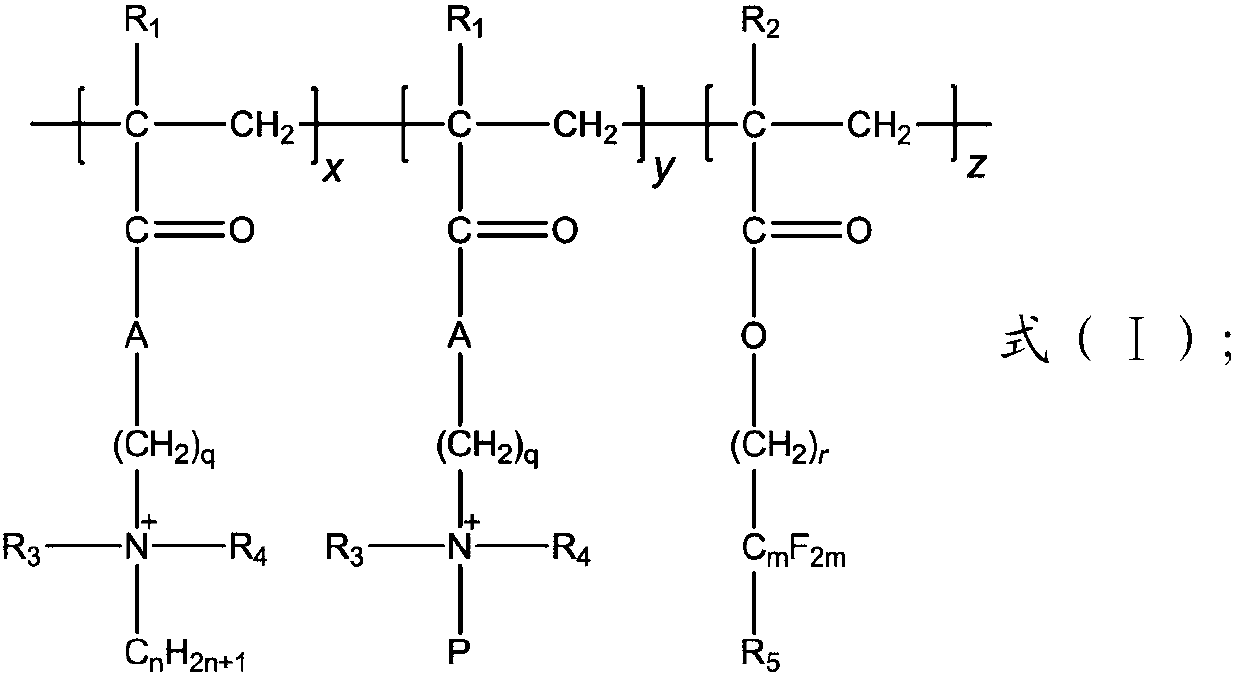

[0081] a) providing a solution of a crosslinkable random copolymer, the crosslinkable random copolymer comprising a structure shown in formula (I);

[0082] b) attaching the solution of the cross-linkable random copolymer to the surface of the substrate, and irradiating with ultraviolet light, forming a cross-linked network structure antibacterial layer on the surface of the substrate;

[0083] c) Infiltrating the antibacterial layer with cross-linked network structure with lubricating oil to obtain a super slippery antibacterial material.

[0084] In the preparation method provided by the present invention, firstly, a solution of crosslinkable random copolymer is provided. Wherein, the solution of the crosslinkable random copolymer is composed of a crosslinkable random copolymer and a solvent, and the specific structure of the cro...

Embodiment 1

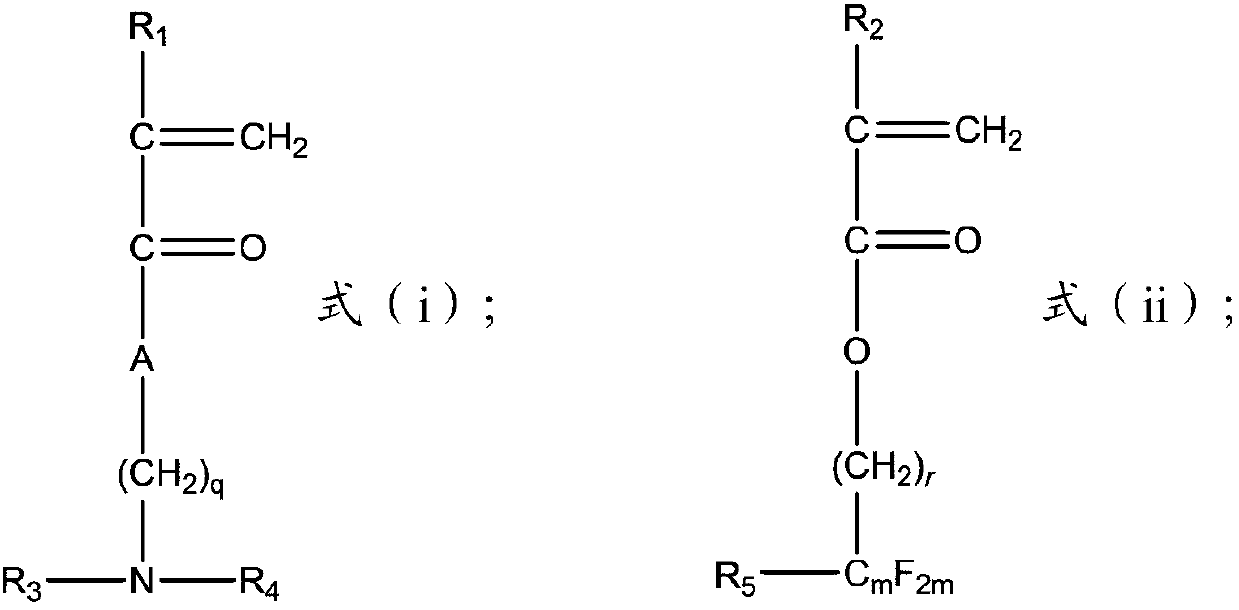

[0106] 1) Synthesis of crosslinkable random copolymers:

[0107] Add 1.6 mg of initiator azobisisobutyronitrile, 1.57 g of dimethylaminoethyl methacrylate, 10.81 g of trifluorooctyl methacrylate, and 35 mL of toluene as a solvent into the three-necked flask. The air in the bottle was purged with nitrogen for 10 min. The reaction was protected with nitrogen, sealed, and stirred and refluxed at 50°C for 24h. After the mixture was cooled to room temperature, cold ethanol was added until the precipitation of the copolymer was complete. Filter and dry in vacuo to obtain poly(dimethylaminoethyl methacrylate-co-tridecafluorooctyl methacrylate) copolymer. The above copolymer was dissolved in 30 mL of toluene, 1.44 g of dodecane chloride and 0.83 g of 3-(bromomethyl)benzophenone were added, and the mixture was reacted at 60° C. for 24 h. After the reaction was completed, rotary evaporation and vacuum drying gave a light yellow solid. After dissolving the light yellow solid with a l...

Embodiment 2

[0115] 1) Synthesis of crosslinkable random copolymers:

[0116] Add 2.0 mg of initiator azobisisobutyronitrile, 0.57 g of dimethylaminoethyl acrylate, 8.64 g of 2-(perfluorohexyl) ethyl methacrylate, and 20 mL of toluene into the three-necked flask. The air in the bottle was purged with nitrogen for 10 min. The reaction was protected with nitrogen, sealed, and stirred and refluxed at 60°C for 18h. After the mixture was cooled to room temperature, cold ethanol was added until the precipitation of the copolymer was complete. Filter and dry in vacuum to obtain poly(dimethylaminoethyl acrylate-co-2-(perfluorohexyl)ethyl methacrylate) copolymer. The above copolymer was dissolved in 15 mL of toluene, 0.54 g of chloro-n-octane and 0.12 g of 2-bromomethylanthraquinone were added, and the reaction was carried out at 60° C. for 24 h. After the reaction was completed, rotary evaporation and vacuum drying gave a light yellow solid. After dissolving the light yellow solid with a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com