High-purity molybdenum rhenium lanthanum ternary alloy guide rod and production process thereof

A ternary alloy and production process technology, applied in the field of alloy materials, can solve the problems of a wide range of strength, many cracks, low qualification rate, etc., and achieve the effects of small strength range, strict addition amount, and control of production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: The composition of the alloy material is less, and the change in content is small. The present invention is only described in detail through this example. It has been verified that the influence of composition change and temperature change on the performance of the guide rod can be ignored compared with the existing guide rod.

[0024] A high-purity molybdenum-rhenium-lanthanum ternary alloy guide rod. The alloy material for preparing the guide rod includes the following components in parts by weight: 1-2 parts of rhenium, 1-2 parts of lanthanum, and 90-100 parts of molybdenum.

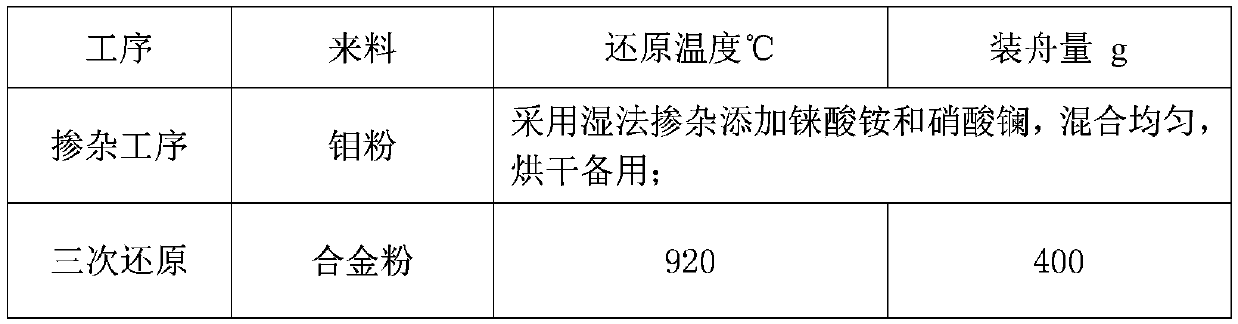

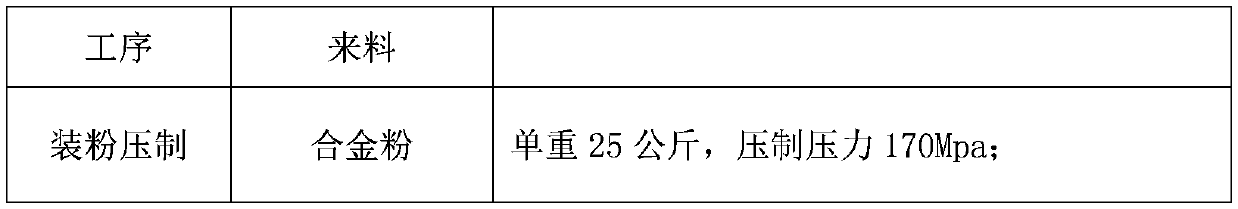

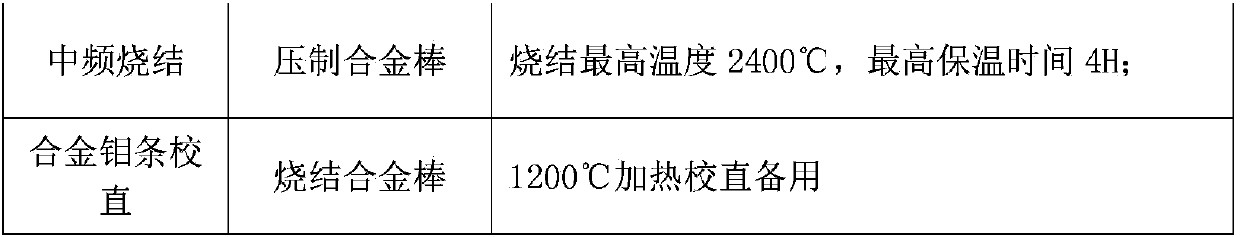

[0025] The production process of the high-purity molybdenum-rhenium-lanthanum ternary alloy guide rod comprises the following steps:

[0026] (1) Preparation of molybdenum powder: Roast ammonium molybdate as a molybdenum source to obtain molybdenum trioxide, then perform a reduction reaction to reduce molybdenum trioxide to molybdenum dioxide, and then perform a second reduction reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com