Graphene thin film macroscopic quantity preparation method

A graphene film and macro technology, which is applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of limited output of a single furnace, and achieve the improvement of single furnace output, large single furnace output and process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

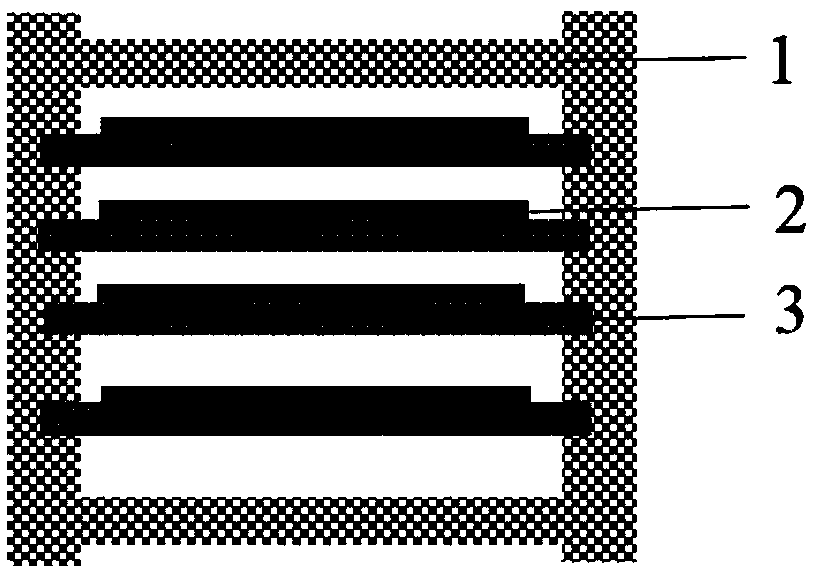

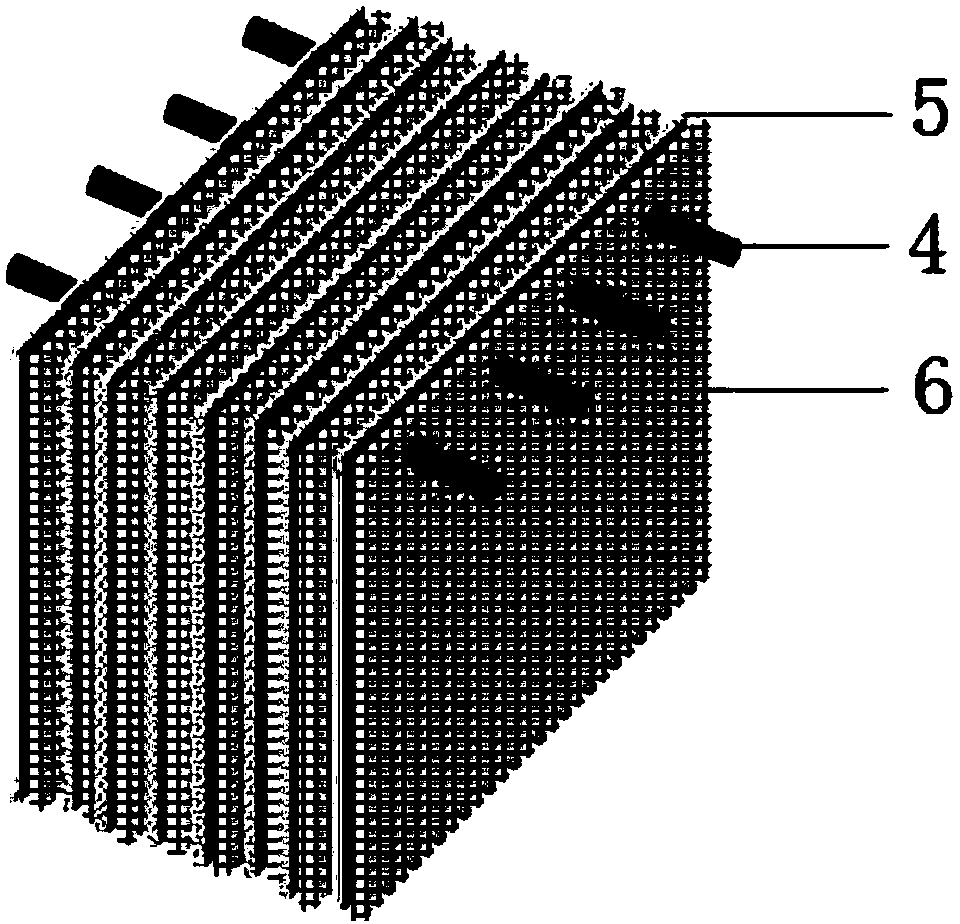

[0065] In one embodiment of the present invention, a kind of graphene film macro-preparation method is provided, such as figure 2 , image 3 As shown, it includes: alternately fixing sheet metal substrates 5 and sheet insulating materials 6 on high temperature resistant rods 4, placing them in a CVD reaction chamber, performing deposition, and cooling.

[0066] The fixing adopts the method of hanging and fixing, and there are at least two high-temperature-resistant rods 4 .

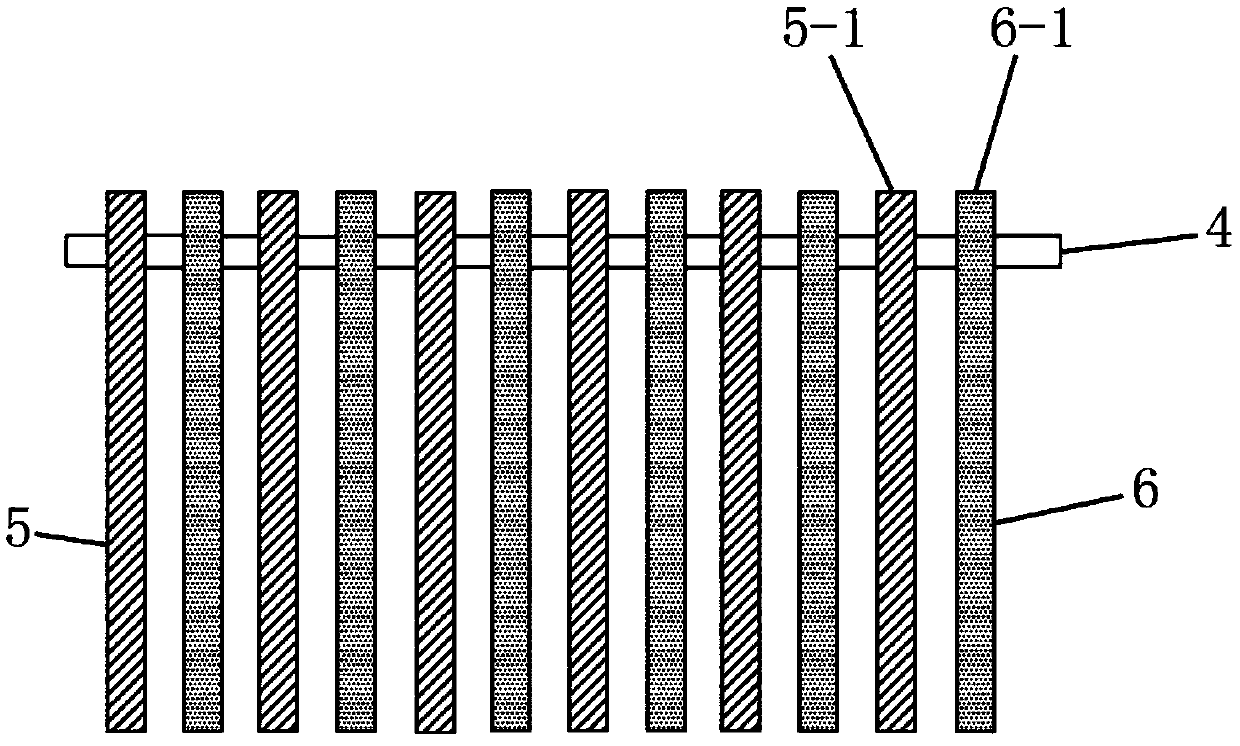

[0067] The method of fixing the sheet metal base 5 and the sheet isolation material 6 with the high temperature resistant rod 4 is adopted: a supply rail is provided on the top edge of the sheet metal base 5 and the sheet isolation material 6 respectively. The holes pierced by the high temperature resistant rods 4 are used to string the sheet metal base 5 and the sheet insulating material 6 alternately through the holes. As a preferred embodiment, when the sheet metal base 5 and the sheet isolation mat...

Embodiment 1

[0085] A kind of graphene film macro preparation method, such as figure 2 and image 3 shown:

[0086] 1) Cut the copper foil 5 (thickness 25μm) used for graphene growth into sheets of 350mm×300mm, cut the high thermal conductivity graphite film 6 (thickness 25μm) into sheets of 355mm×305mm, and cut 200 sheets each;

[0087] 2) On the copper foil 5, punch a row of holes along the long side, the hole diameter is 5mm, the hole spacing is 20mm, and the distance between the center line of the hole and the top edge of the copper foil 5-1 is 15mm, on the high thermal conductivity graphite film 6 along the edge Drill a row of holes on the long side, the hole diameter is 5mm, the hole spacing is 20mm, and the distance between the center of the hole and the top edge of the high thermal conductivity graphite film is 6-1, and the distance is 16mm;

[0088] 3) Place the punched 200 copper foils 5 and 200 graphite thermal conductive films 6 alternately, align the holes, string them with...

Embodiment 2

[0092] A kind of graphene film macro preparation method, such as figure 2 and image 3 shown:

[0093] 1) Cut the copper foil 5 (thickness 25μm) used for graphene growth into sheets of 350mm×300mm, and cut the nickel foil 6 (thickness 25μm) into sheets of 355mm×305mm, each with 200 sheets;

[0094] 2) On the copper foil 5, punch a row of holes along the long side, the hole diameter is 5mm, the hole spacing is 20mm, and the distance between the center line of the hole and the top edge 5-1 of the copper foil is 15mm, and on the nickel foil 6 along the long side Punch a row of holes, the hole diameter is 5mm, the hole spacing is 20mm, and the distance between the center line of the hole and the top edge of the nickel foil is 6-1, and the distance is 16mm;

[0095] 3) Alternately place 200 pieces of copper foil 5 and 200 pieces of nickel foil 6 with holes, align the holes, string together with quartz rods 4 and place them on the bracket, and hang up the copper foil 5 and the ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com