High-speed hydraulic valve driving device and high-speed hydraulic valve

A driving device and hydraulic valve technology, applied in the field of high-speed hydraulic valves, can solve the problems that the digital hydraulic system does not show work efficiency, the rated flow performance lacks in-depth research, and the valve control energy consumption of the digital hydraulic system is small. The effect of step-by-step control of driving force, good hydraulic system adaptability, and fast dynamic coupling response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

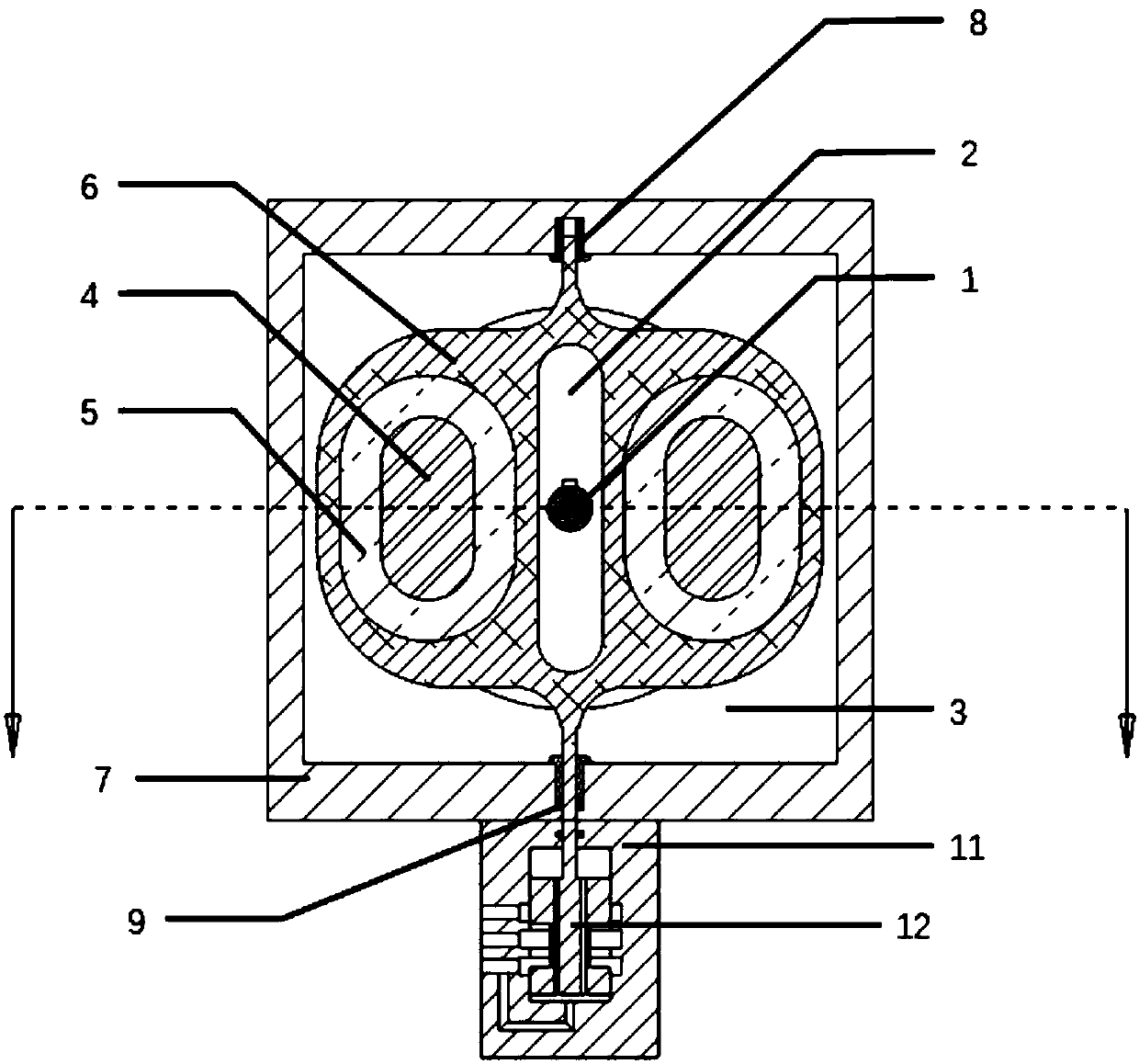

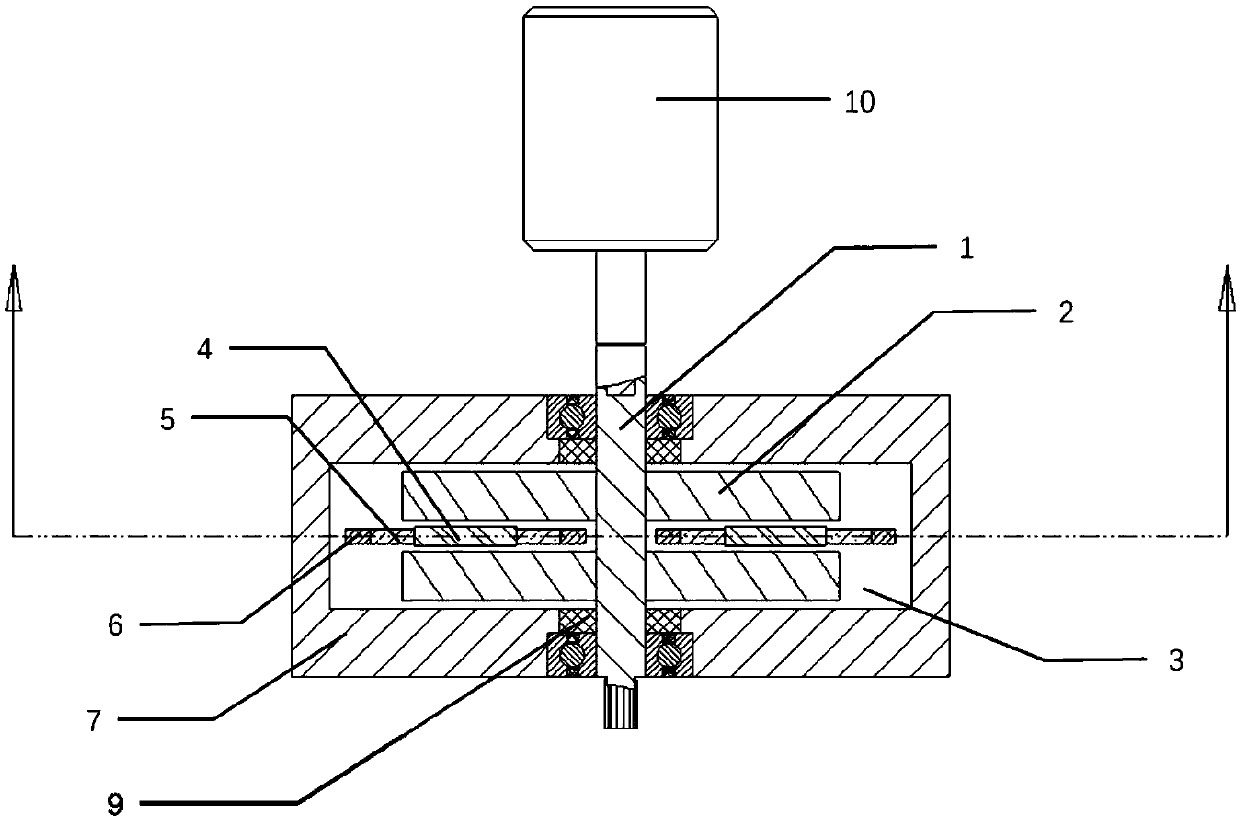

[0032] A structural schematic diagram of a driving device for a high-speed hydraulic valve and a high-speed hydraulic valve described in this embodiment is shown in Figure 1 to Figure 3 shown.

[0033] This embodiment takes the structure equipped with two turntables as an example to illustrate the driving device of the high-speed hydraulic valve and the structure of the high-speed hydraulic valve, but those skilled in the art can understand that the driving device of the high-speed hydraulic valve equipped with one or more turntables The structure principle is the same.

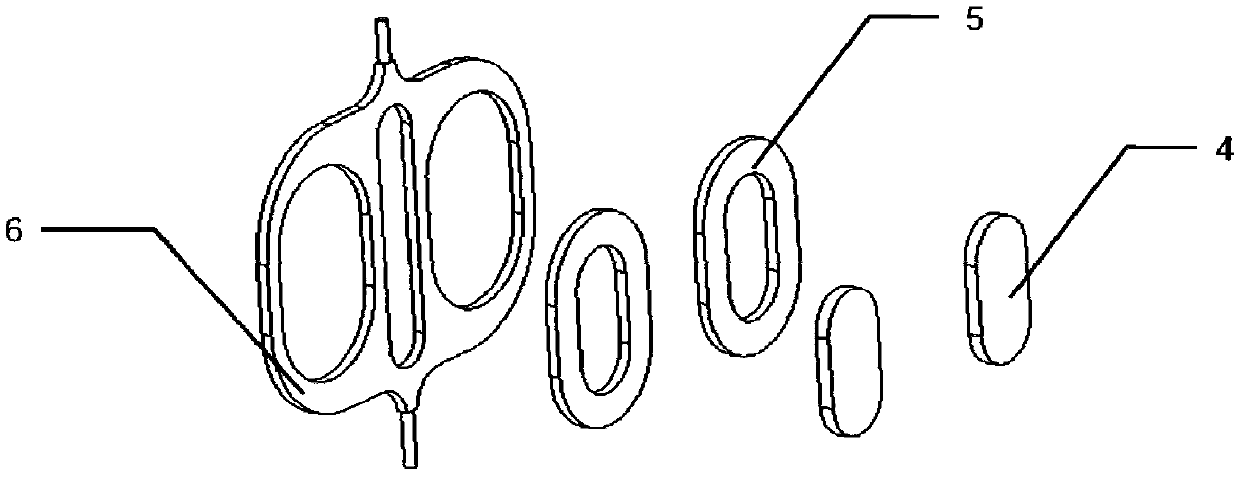

[0034] Such as Figure 1-3 As shown, a driving device for a high-speed hydraulic valve described in this embodiment consists of a rotating shaft 1, two turntables 2, a magneto-rheological fluid 3, two magnetic cores 4, two excitation coils 5, a The linear translator 6, a housing 7, two bearings 8, three sealing rings 9 and a hydraulic pump 10 are composed. The rotating disk 2 is made of a magnetically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com