Screening method for diffusion barrier layer of thermoelectric component

A screening method and barrier layer technology are applied in the field of screening of diffusion barrier materials of thermoelectric components, which can solve the problems of long R&D cycle, low R&D efficiency and high cost of barrier materials, and achieve the effect of fast and low-cost screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

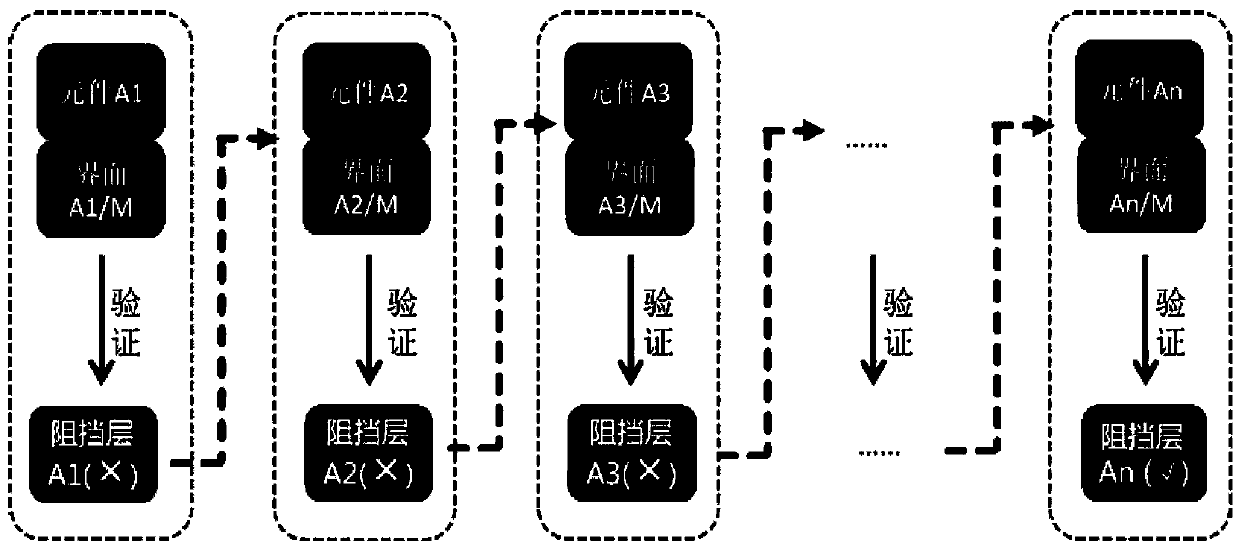

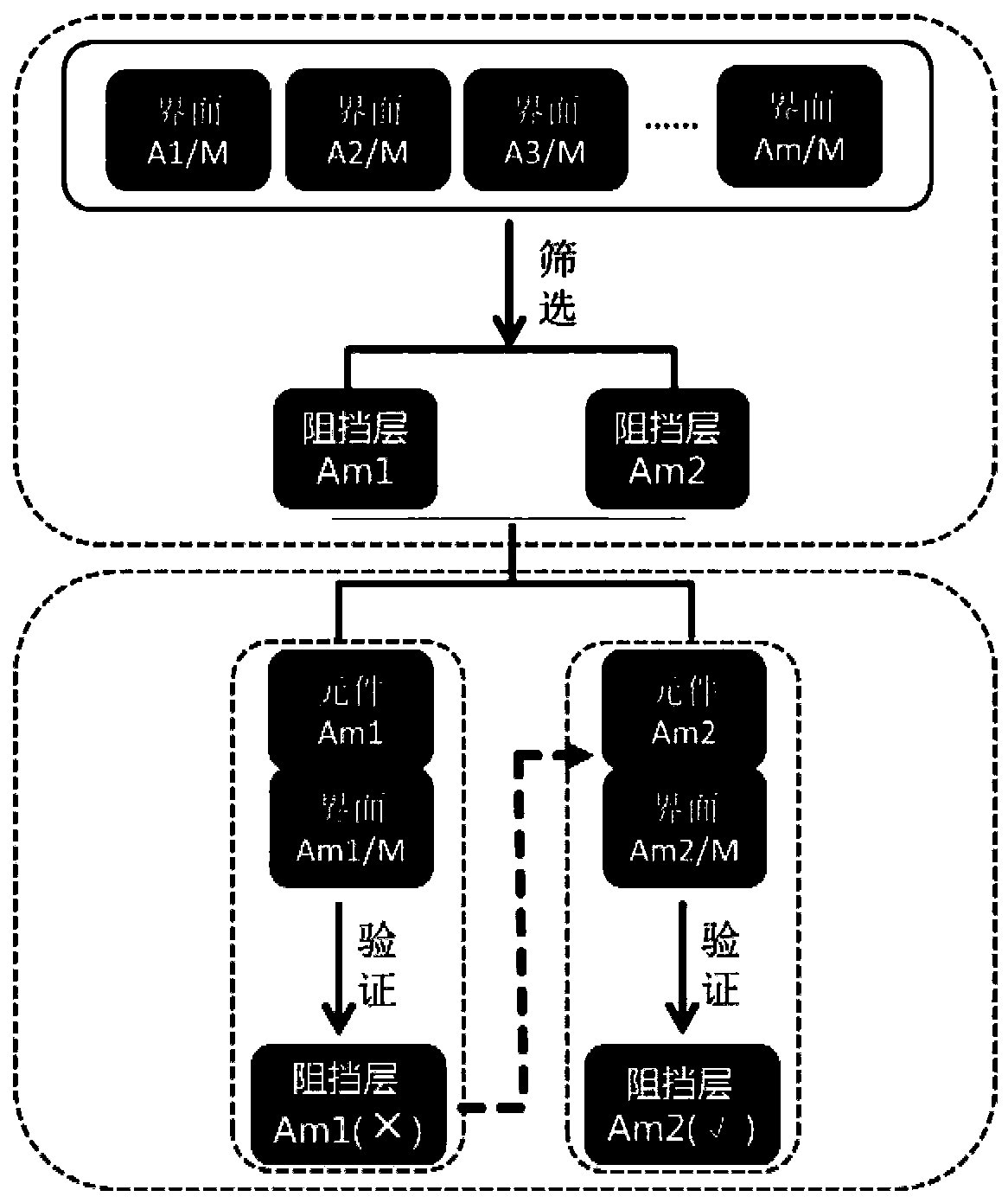

Method used

Image

Examples

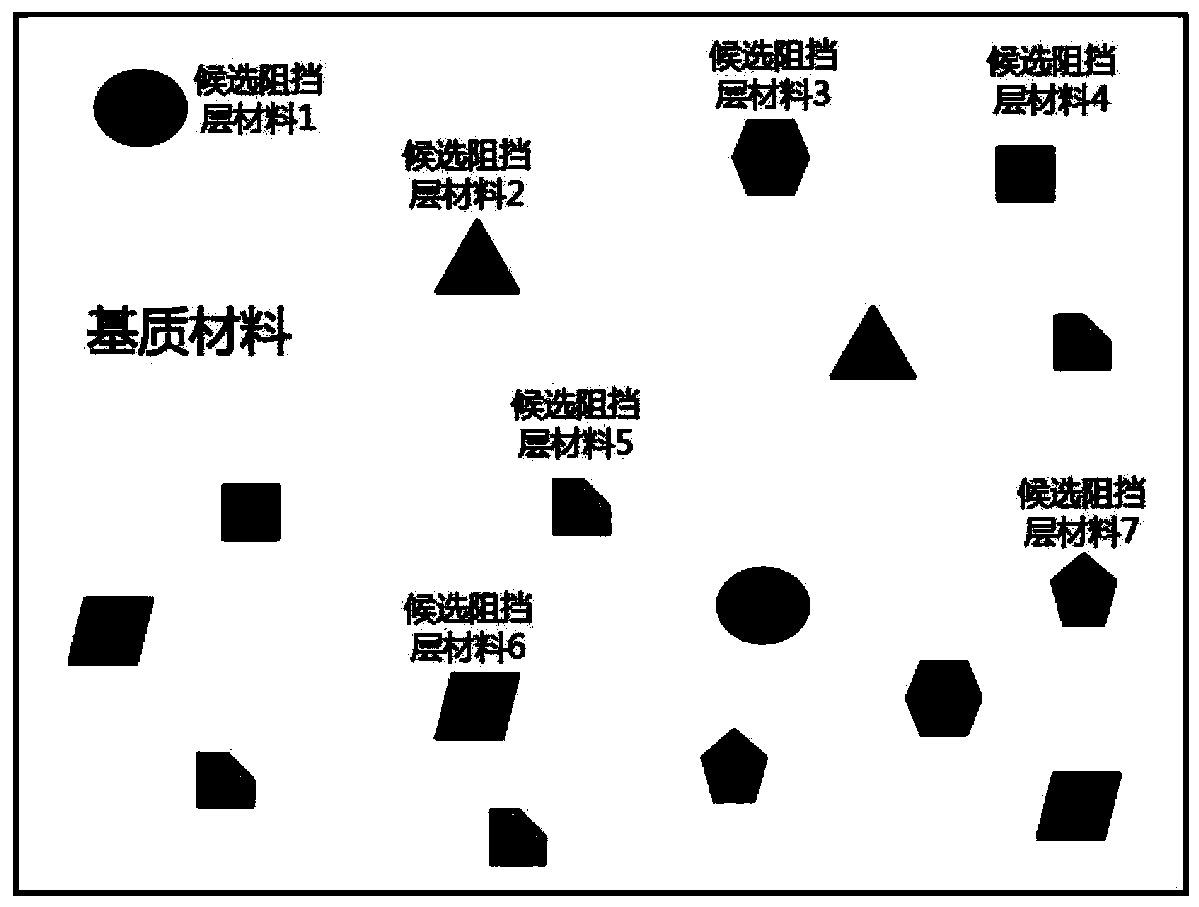

Embodiment 1

[0054] Take the component as Yb 0.3 co 4 Sb 12 n-type skutterudite powder (n-SKD) 2.5g, take Ti(4N, 45um), Zr(3N, 75um), Hf(3N, 75um), V(3N, 75um), Nb(4N, 45um) , Ta, Cr (3N5, 150um), Mo (3N, 75um), W (3N, 75um) powders, each 0.02g, mixed with n-SKD powder evenly. Put the mixed powder into a graphite mold with a diameter of 12.7mm, put the mold into an SPS sintering system, and conduct spark plasma rapid sintering under vacuum: the chamber pressure is <10Pa, the sintering pressure is 64MPa, the heating rate is 80°C / min, and the sintering temperature is 620°C , the holding time is 10 min, the cooling rate is 60 °C / min, and the temperature is lowered to 200 °C and then cooled in the furnace to obtain a densified co-sintered sample, which contains the interface between the above nine candidate barrier particles and the n-SKD matrix material. The above-mentioned co-sintered samples were sealed in a vacuum quartz tube and heated at 650°C for 2 days. The surface of the heat-dura...

Embodiment 2

[0058] Take the component as Yb 0.3 co 4 Sb 12 Put 4g of n-type skutterudite powder (n-SKD) into a graphite mold with a diameter of 12.7mm, put the mold into an SPS sintering system, and perform discharge plasma rapid sintering under vacuum: chamber pressure -3 Pa, continue pumping, and start to heat up at the same time. After 30 minutes, the chamber temperature reaches 200°C, keep it warm for half an hour, then feed high-purity Ar, and sputter the Mo target with 1.5kW power for 40 minutes under the chamber pressure of 1.1Pa. After the sputtering is over, the equipment is turned off, the sample is cooled with the furnace, and the chamber temperature is lower than 70°C, then the cabin is opened and the sample is taken out. The sample was cut by wire cutting to obtain the structure Mo / Yb 0.3 co 4 sb 12 The thermoelectric element and the corresponding macroscopic interface. The above-mentioned components were sealed in a vacuum quartz tube, and heated at 650°C for 2 days. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com