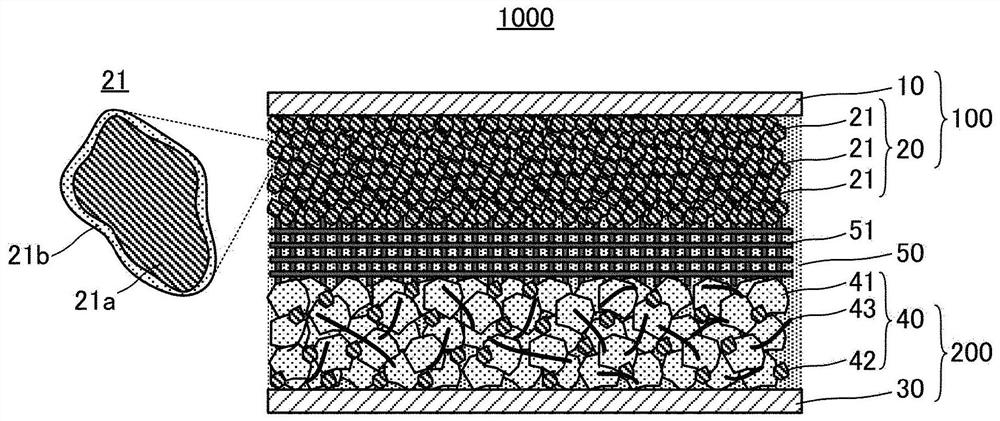

Manufacturing method of negative electrode active material composite, aqueous lithium ion secondary battery and manufacturing method thereof

A technology of negative electrode active material and secondary battery, which is applied in the direction of active material electrode, secondary battery, electrode manufacturing, etc., can solve the problems of narrow potential window and limitation of active material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

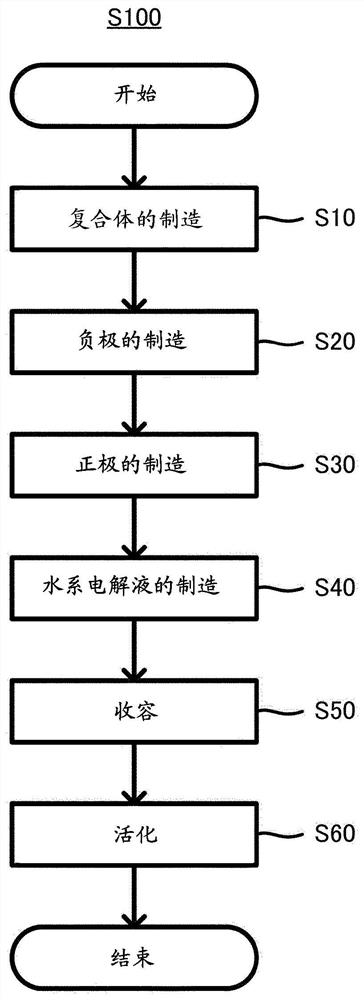

[0132] 1. Fabrication of Negative Electrode

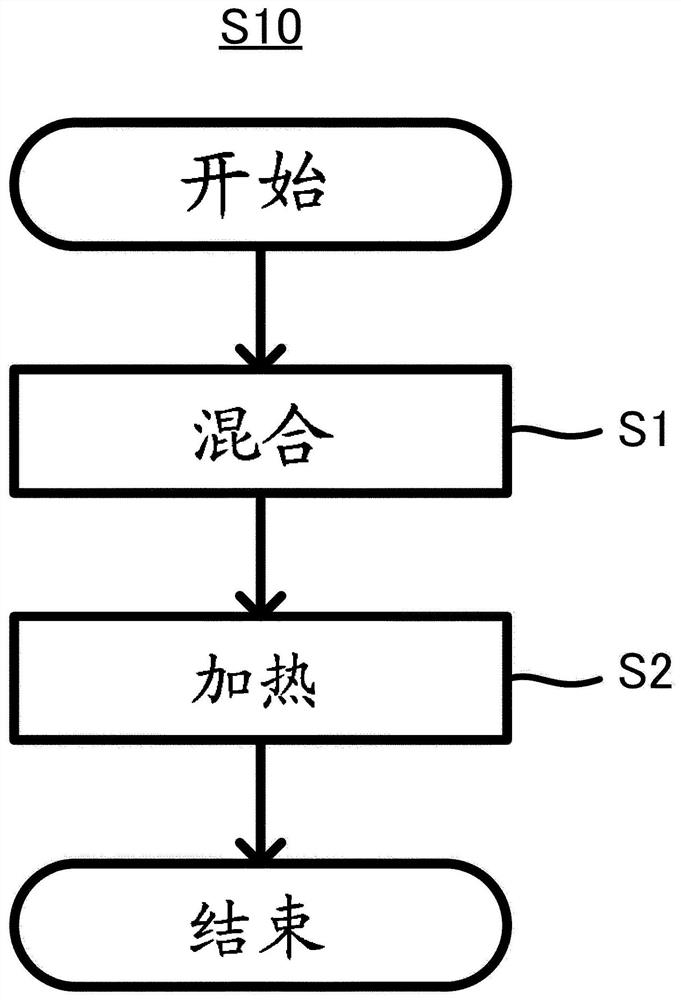

[0133] Acetylene black (manufactured by Denka Co., Ltd.) and PTFE dispersion (manufactured by Asahi Glass Co., Ltd. AD911E) as the negative electrode active material were mixed so that the solid content ratio (weight ratio) became 7:3, and a dispersant (Nakalai Tesque Co., Ltd. Triton X-100 manufactured by a company), and a slurry was prepared. The obtained slurry was coated on the surface of a graphite sheet (manufactured by Toyo Tanso Co., Ltd.) as a negative electrode current collector. After natural drying, heating at 360°C above the glass transition temperature of PTFE and below the gasification temperature, thereby forming a negative electrode active material layer formed of a composite of acetylene black and PTFE on the surface of the graphite sheet, to obtain negative electrode.

[0134] 2. Manufacturing of batteries

[0135] The obtained negative electrode was used as a working electrode, an Ag / AgCl electrode (saturated...

Embodiment 2

[0139] The activation step was performed on the battery obtained in the same manner as in Example 1. Specifically, between -2V and 0V relative to the reference electrode (in terms of Li / Li + The reference meter was between 1.244V and 3.244V), and 20 cycles of scanning were repeated at 10 mV / s, and the battery was evaluated in the same manner as in Example 1. It should be noted that this activation process is the same as that of the secondary battery at the rate of Li / Li + It is synonymous to repeat 20 cycles of charge and discharge between the reference meter 1.244V and 3.244V. Show the results of the evaluation in Figure 5 .

Embodiment 3

[0141] Batteries were fabricated and evaluated in the same manner as in Example 2, except that the aqueous electrolyte solution was changed to a saturated solution at 25°C. Show the results of the evaluation in Figure 6 . In addition, it is specified that a large amount of salt is thrown into water and stirred to dissolve it, and a "saturated solution" is obtained when the amount of added salt and the amount of precipitated salt are in the same state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com