Battery power system

A technology of power system and battery management system, applied in the field of lithium battery pack processing, can solve the problems of plate active material, battery overcharge and overdischarge, monitoring and protection, etc., to maintain reliability and efficiency, and prolong service life , the effect of preventing overcharge or overdischarge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

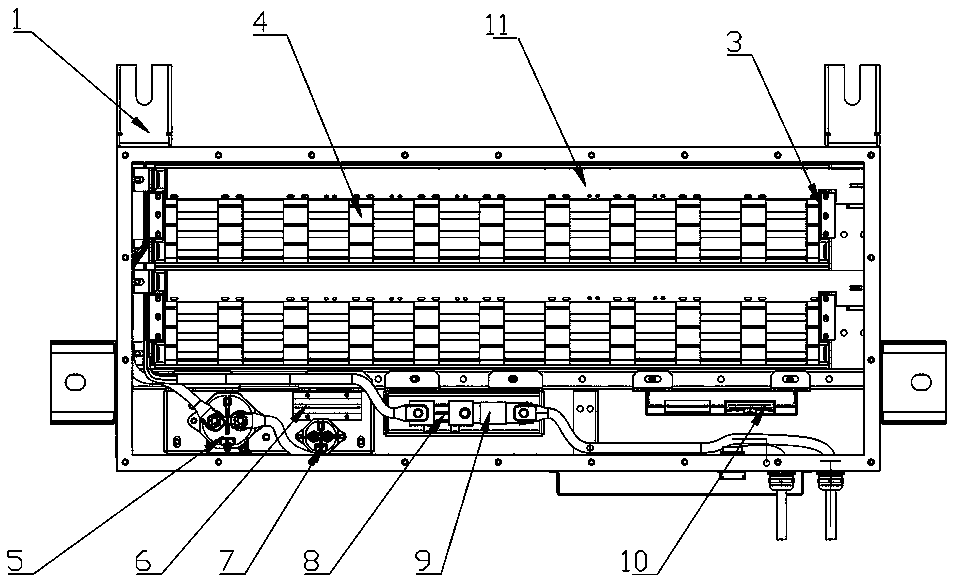

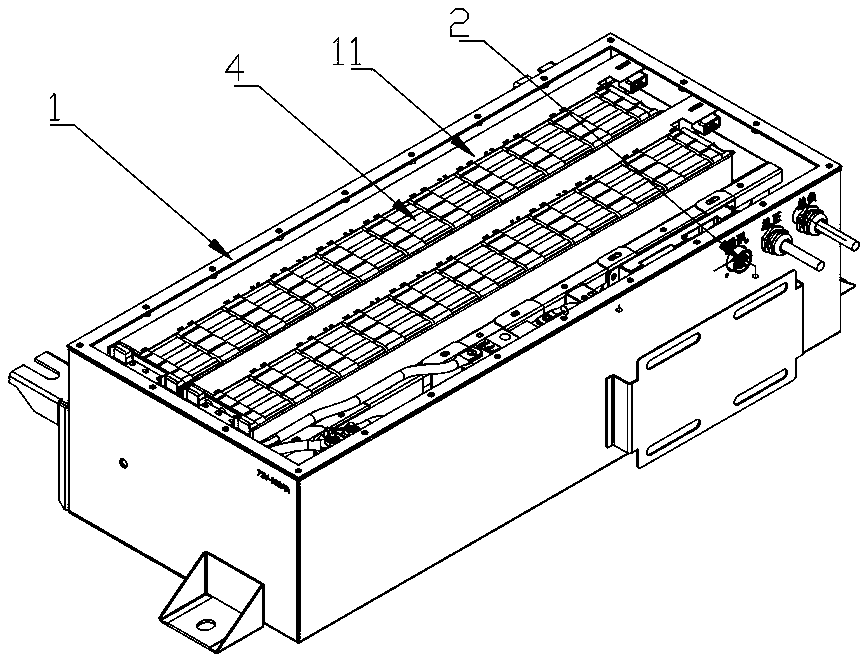

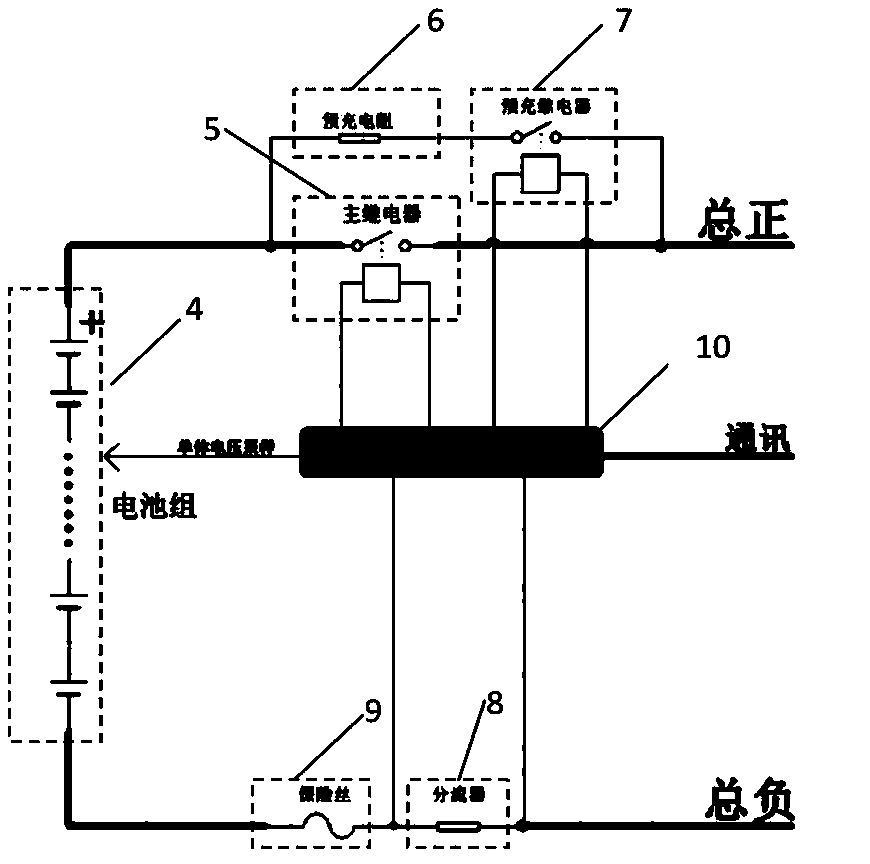

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a battery power system for low-speed micro electric vehicles, including a battery box 1, and a battery clamp assembly 3 is arranged in the battery box 1, which is used to assemble a plurality of ternary lithium batteries into a battery Module 4, one side of the battery module 4 is also provided with a pre-charging unit and a battery management system 10, and the battery management system 10 is provided with a battery voltage data acquisition board 11 for connecting with the battery module 4 to collect battery module data in real time. 4. Voltage and current data during the charging and discharging process. When the collected data is greater than the preset threshold, the battery management system 10 controls the pre-charging unit to disconnect fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com