Natural sugarcane juice processing method

A processing method, technology of sugarcane juice, applied in food ion exchange membrane method, food ingredients as antioxidant, food science, etc., can solve the problems of nutrient loss, easy deterioration of sugarcane juice, short storage period, etc., to extend the shelf life , good sensory and nutritional quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The representative variety of green-skinned fruit cane, Xuecane (origin in Datian County, Sanming City), was selected for sugarcane juice processing. Fruit cane with intact skin, no mechanical damage, and no pests and diseases was selected, the roots and leaves were removed, and the fruit cane was cut into sugarcane segments with a length of about 30 cm. Clean the sugarcane skin dirt with flowing water. The cleaned sugarcane is fed into the juice extractor for juice extraction and passed through a 0.07mm stainless steel filter. Quickly add 0.5wt% sodium D-isoascorbate and 0.01wt% citric acid to the rough-filtered cane juice. Pour the prepared cane juice into the ultrafiltration machine, select a 0.02 μm filter membrane, and the volume of the clarified cane juice after filtration is 15% of the initial volume. The clarified sugarcane juice after ultrafiltration was filled into non-transparent PET bottles and sealed with aluminum foil. The packaged sugarcane juice was s...

Embodiment 2

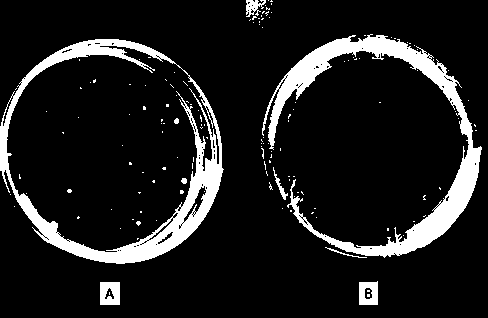

[0028] The sugarcane variety and place of production are the same as in Example 1. Cut the fruit cane with intact skin, no mechanical damage, no pests and diseases, and the length of the cut is about 30 cm. After the cut fruit cane segments are washed with flowing water, they are pressed. Cane juice is coarsely filtered through a 0.07 mm filter. Add 1wt% sodium D-isoascorbate and 0.02wt% citric acid to the coarsely filtered cane juice. The prepared sugarcane juice is passed through a 0.4 micron PVDF membrane for ultrafiltration treatment, and the volume of the clarified sugarcane juice is reduced by 80% after filtration. The cane juice after ultrafiltration is filled, and the filling parameters are the same as in Example 1. The cane juice after filling was stored at 4°C. figure 2 It is the sensory color of sugarcane juice stored for 1 day after the treatment of the present invention (A: rough filtered cane juice, B: ultrafiltered cane juice), and the results show that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com