Co-based ammonia synthesis catalyst under mild condition and preparation method thereof

A catalyst, a technology for ammonia synthesis, which is used in the preparation/separation of ammonia, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of easy sintering and high cost of precious metal catalysts, and achieve low cost, good ammonia synthesis performance, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

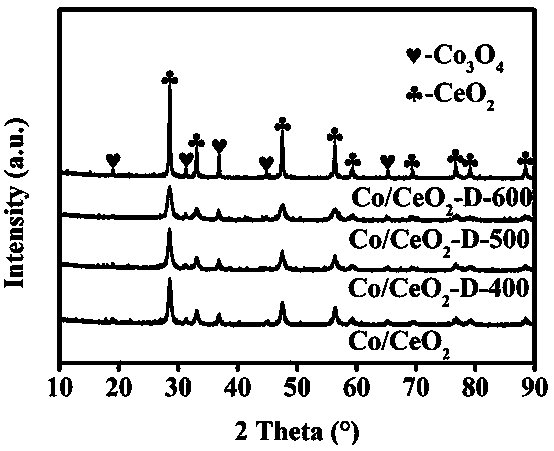

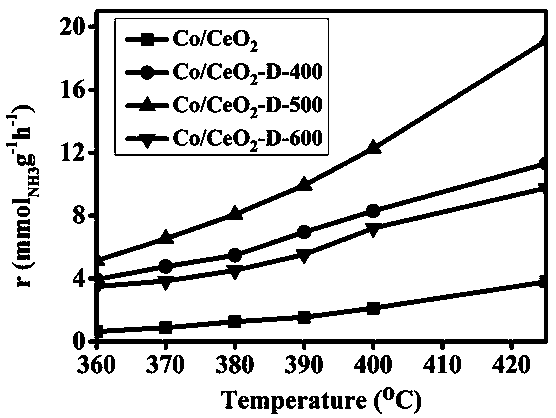

Embodiment 1

[0025] Step A: Weigh 15.194g of cerium nitrate hexahydrate and add 100ml of deionized water to prepare a 0.35mol / L cerium nitrate aqueous solution, add 7.408g of cobalt nitrate, stir rapidly for 0.5h, and then transfer the obtained solution to a 40°C In an oil bath, add 2mol / L KOH precipitant drop by drop under stirring conditions until complete precipitation and aging for 1h, then take it out and cool it to room temperature, then centrifuge several times, and dry at 120°C for 24h to obtain Co / CeO 2 .

[0026] Step B: 0.5g Co / CeO 2 The composite metal oxide was added to tris buffer solution (100mL, pH=8.5) containing dopamine (1mg / mL) and stirred for 24h. The suspension was separated by centrifugation, washed three times with deionized water and once with ethanol, and then dried under vacuum at 40 °C for 12 h.

[0027] Step C: The product obtained in step B is in N 2 Annealing treatment at 400°C for 2h in atmosphere.

[0028] Step D: The product obtained in step C is in O ...

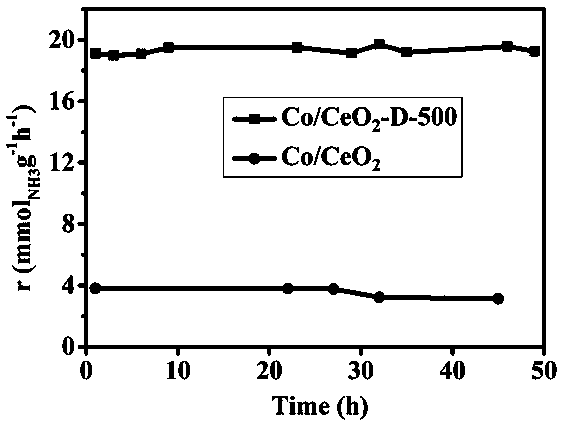

Embodiment 2

[0030] Step A: Weigh 15.194g of cerium nitrate hexahydrate and add 100ml of deionized water to prepare a 0.35mol / L cerium nitrate aqueous solution, add 7.408g of cobalt nitrate, stir rapidly for 0.5h, and then transfer the obtained solution to a 40°C In an oil bath, add 2mol / L KOH precipitant drop by drop under stirring conditions until complete precipitation and aging for 1h, then take it out and cool it to room temperature, then centrifuge several times, and dry at 120°C for 24h to obtain Co / CeO 2 .

[0031] Step B: 0.5g Co / CeO 2 The composite metal oxide was added to tris buffer solution (100mL, pH=8.5) containing dopamine (1mg / mL) and stirred for 24h. The suspension was separated by centrifugation, washed three times with deionized water and once with ethanol, and then dried under vacuum at 40 °C for 12 h.

[0032] Step C: The product obtained in step B is in N 2 Annealing treatment at 500°C for 2h in the atmosphere.

[0033] Step D: The product obtained in step C is i...

Embodiment 3

[0035] Step A: Weigh 15.194g of cerium nitrate hexahydrate and add 100 ml of deionized water to prepare a 0.35mol / L cerium nitrate aqueous solution, then add 7.408g of cobalt nitrate, stir rapidly for 0.5h, and then transfer the obtained solution to 40 ℃ oil bath, add 2mol / L KOH precipitant drop by drop under the condition of stirring until complete precipitation and aging for 1h, then take it out and cool to room temperature, then centrifuge several times, and dry at 120℃ for 24h to obtain Co / CeO 2 .

[0036] Step B: 0.5g Co / CeO 2 The composite metal oxide was added to tris buffer solution (100mL, pH=8.5) containing dopamine (1mg / mL) and stirred for 24h. The suspension was separated by centrifugation, washed three times with deionized water and once with ethanol, and then dried under vacuum at 40 °C for 12 h.

[0037] Step C: The product obtained in step B is in N 2 Annealing treatment at 600°C for 2h in the atmosphere.

[0038] Step D: The product obtained in step C is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com