A kind of ruthenium-based ammonia synthesis catalyst with cerium oxide as carrier

A cerium oxide and catalyst technology, applied in the field of ruthenium-based ammonia synthesis catalyst and preparation thereof, can solve problems such as unfavorable ruthenium catalyst ammonia synthesis activity, increase in catalyst particle size, etc., achieve inhibition of sintering growth, promotion of interaction, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

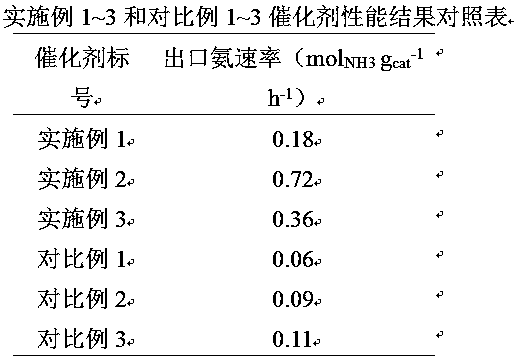

Examples

Embodiment 1

[0029] Take 3g of cerium oxide and impregnate an equal volume of 0.015 g / mL nitrosoruthenium nitrate aqueous solution into Ru:CeO 2 The mass ratio of the sample is 0.10:1. After drying, the sample is placed in a tube furnace, and a mixed gas of NO and nitrogen is introduced. In terms of volume percentage, the NO in the mixed gas is 2%, and the nitrogen is 98%. The flow rate of the gas is 30 mL / min. After heat treatment at 250°C for 40 hours, in 5% H 2 and 95% Ar mixed gas at 300° C. for 45 hours to obtain the cerium oxide-supported ruthenium-based ammonia synthesis catalyst.

Embodiment 2

[0031] Take 3g of cerium oxide and impregnate an equal volume of 0.015 g / mL nitrosoruthenium nitrate aqueous solution into Ru:CeO 2 The mass ratio of the sample is 0.60:1. After drying, the sample is placed in a tube furnace, and a mixed gas of NO and argon is introduced. In terms of volume percentage, the mixed gas contains 35% NO and 65% argon. The flow rate is 900 mL / min. After heat treatment at 550°C for 4 hours, in pure H 2 The cerium oxide-supported ruthenium-based ammonia synthesis catalyst was obtained by reducing in air at 500° C. for 5 hours.

Embodiment 3

[0033] Take 3g of cerium oxide and impregnate an equal volume of 0.015 g / mL nitrosoruthenium nitrate aqueous solution into Ru:CeO 2 The mass ratio of the sample is 0.30:1. After drying, the sample is placed in a tube furnace, and a mixed gas of NO and helium is introduced. In terms of volume percentage, the mixed gas contains 25% NO and 75% helium. The flow rate is 300 mL / min. After heat treatment at 450°C for 10 hours, in 25%H 2 and 75% He mixed gas at 400 ° C for 10 hours to obtain the cerium oxide-supported ruthenium-based ammonia synthesis catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com