X-Sn-Zr reduction catalyst, and preparation method and application thereof

A catalyst and raw material technology, applied in the field of X-Sn-Zr reduction catalyst and its preparation, can solve the problems of high desulfurization efficiency and secondary pollution, and achieve the effect of high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

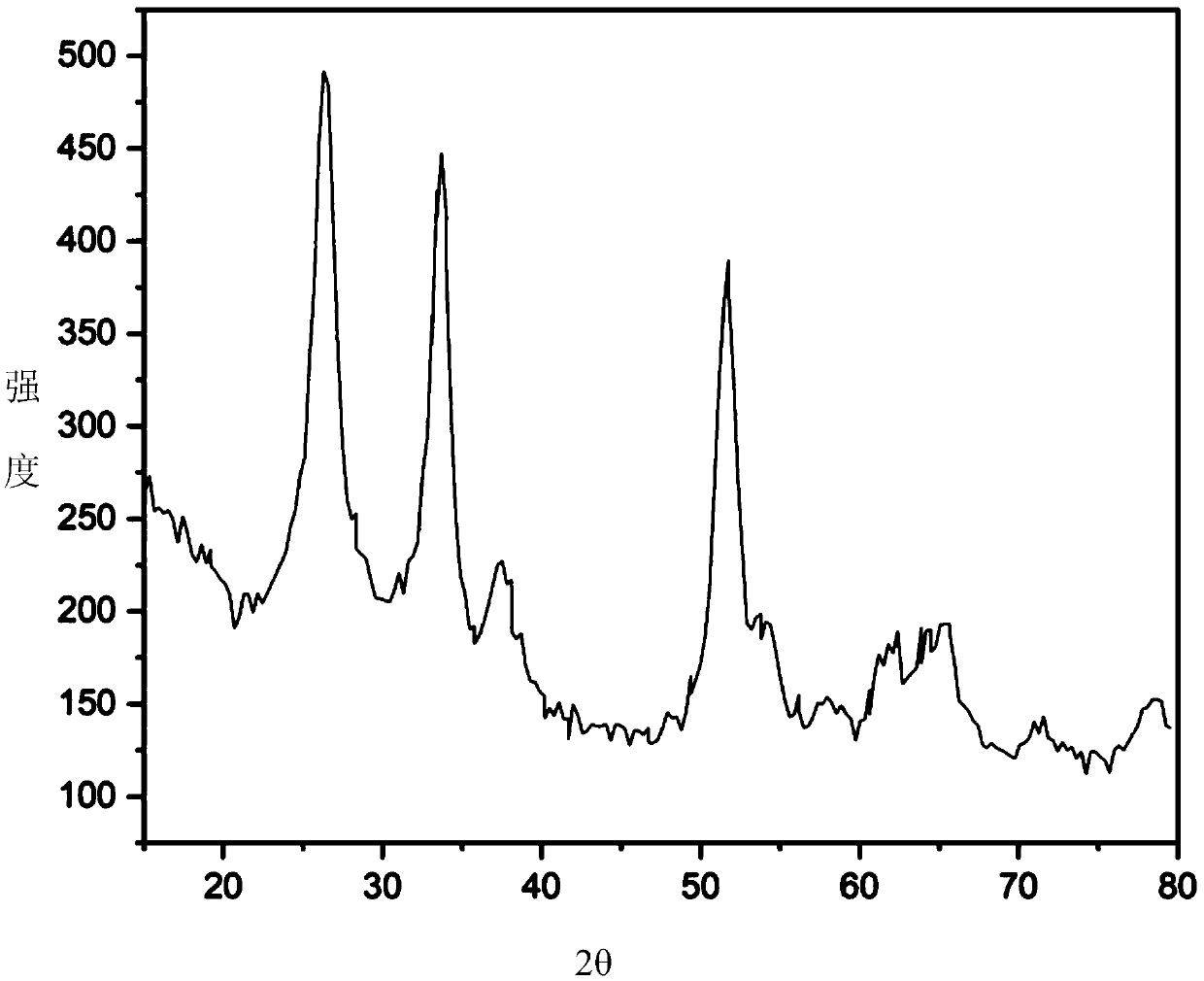

Image

Examples

Embodiment 1

[0060] A kind of Cu loading is the Cu-Sn-Zr reduction catalyst of 5%, the preparation process of this catalyst is as follows:

[0061] (1) Weigh raw materials: 7.012g SnCl 4 , 2.31gZrO(NO 3 ) 2 , 0.657gCu(NO 3 ) 2 ·3H 2 O, dissolved in 100mL of distilled water;

[0062] (2) Adjust the pH value of the solution to 7 with ammonia water, then seal it with a fresh-keeping bag, then pierce about 20 holes in the fresh-keeping bag, age under stirring for six hours in a fume hood at a temperature of 40°C, and filter with suction , placed in an oven and baked at 100-300°C for 12 hours, then baked in a muffle furnace, raised the temperature from room temperature to 600°C, and kept at 600°C for 4 hours, and pressed the calcined catalyst into tablets. Catalysts with Cu loadings of 5% for 30 to 50 meshes were obtained.

Embodiment 2

[0064] The Cu-Sn-Zr reduction catalysts with Cu loadings of 10% and 20% were prepared in the same way as in Example 1, except that the added Cu(NO 3 ) 2 ·3H 2 The amount of O varies.

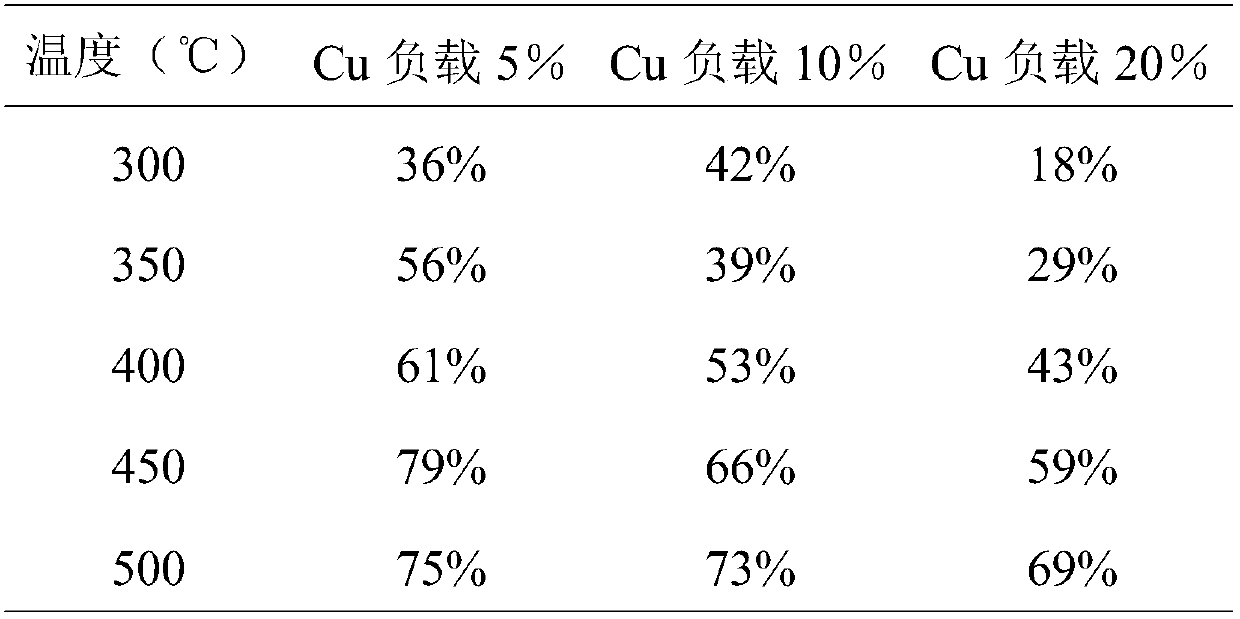

[0065] Table 1 is the SO of the Cu-Sn-Zr catalyst prepared by Example 1 and Example 2 of the present invention 2 conversion rate table

[0066]

[0067] Note: SO 2 Conversion = 1 - outlet SO 2 Concentration / Inlet SO 2 concentration

Embodiment 3

[0069] with SnCl 4 , ZrO(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O is used as a raw material, and it is prepared respectively according to the iron load of 5%, 10%, and 20%, and the specific process is the same as that of the Cu-Sn-Zr catalyst.

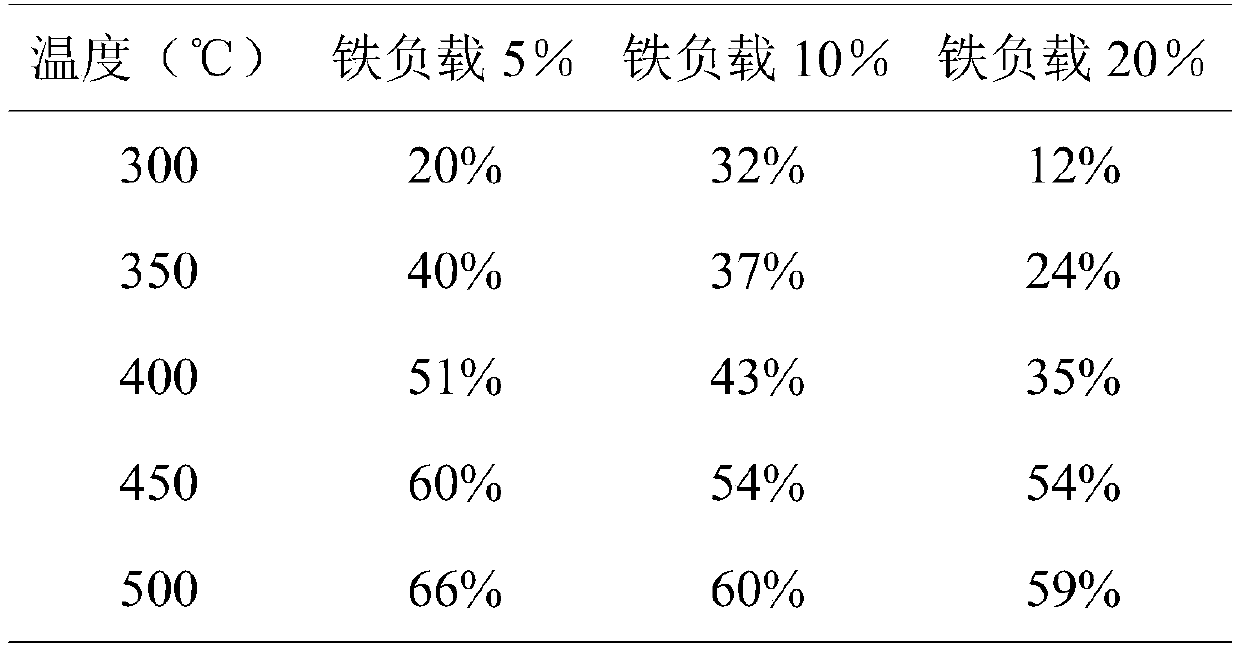

[0070] Table 2 is the SO of the Fe-Sn-Zr catalyst prepared in Comparative Example 1 2 conversion rate table

[0071]

[0072] Note: SO 2 Conversion = 1 - outlet SO 2 Concentration / Inlet SO 2 concentration

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com