Iron-manganese-cobalt co-doped supported Fenton catalyst, preparation method and application thereof

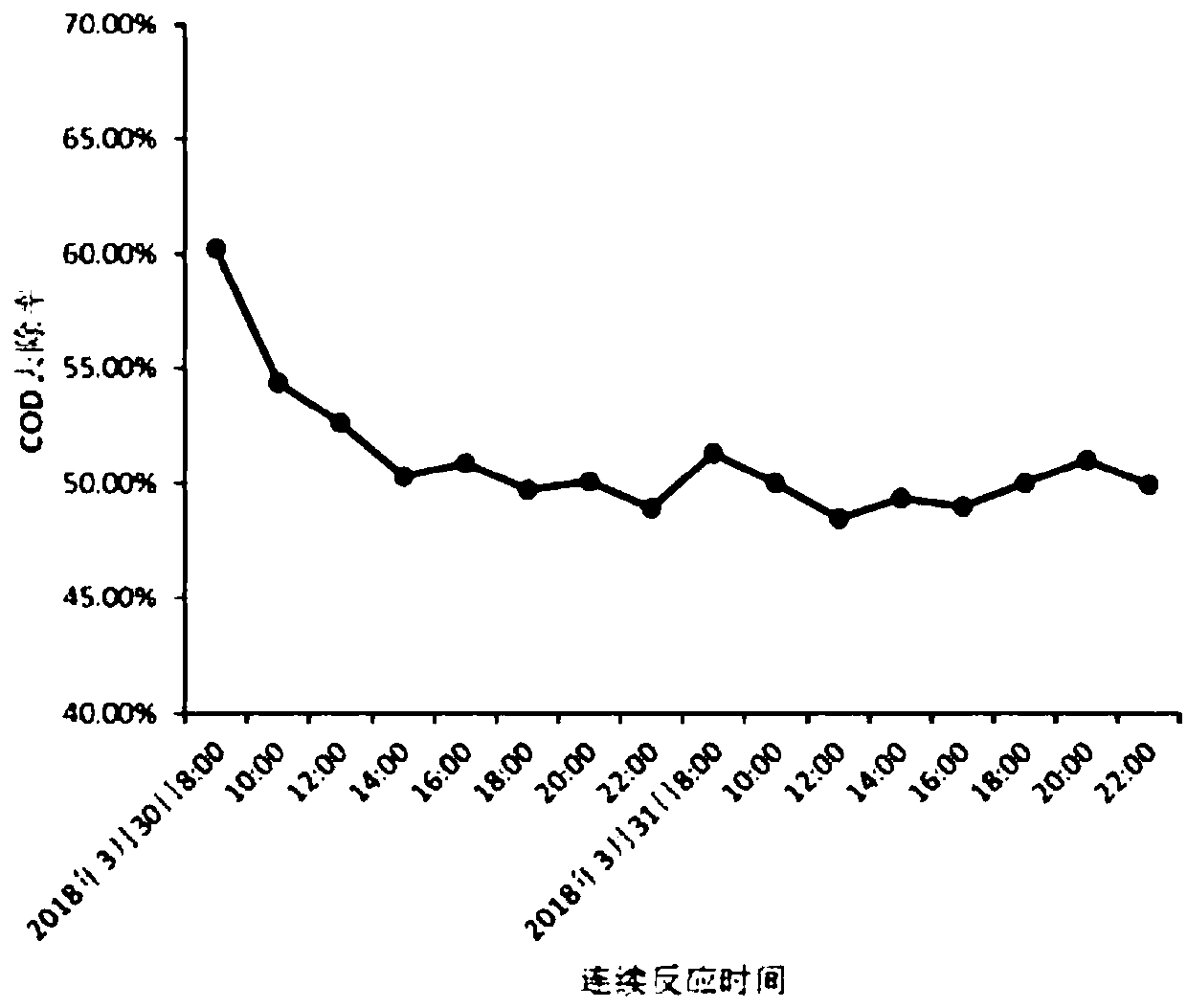

A catalyst and co-doping technology, applied in the direction of chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of single active component, low removal efficiency, surface pH affecting catalyst activity, etc. , to achieve the effects of widening the pH range, stable operation, and stable COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of iron-manganese-cobalt co-doped supported Fenton catalyst is based on TiO 2 -Al 2 O 3 as the carrier, with Fe(NO 3 ) 3 ·9H 2 O, Mn (NO 3 ) 2 ·4H 2 O, CoCl 2 ·6H 2 O is a reaction precursor prepared into a catalyst impregnation solution, prepared by an impregnation method, and then obtained by filtration, washing, drying and roasting.

Embodiment 2

[0035] (1) Carrier pretreatment: TiO with a particle size of 2 to 3 mm 2 -Al 2 O 3 The carrier is decontaminated and dried.

[0036] (2) Preparation of impregnation solution: preparation of Fe 3+ , Mn 2+ and Co 2+ Fe(NO) with a molar concentration ratio of 2:1:1 3 ) 3 ·9H 2 O, Mn (NO 3 ) 2 ·4H 2 O, CoCl 2 ·6H 2 Aqueous O solution, adjusted to pH 6.8 with NaOH.

[0037] (3) Impregnation: the pretreated TiO 2 -Al 2 O 3 The carrier was completely immersed in the prepared immersion solution, stirred slowly at a constant speed, fully immersed for 12 hours, filtered after the immersion, and the catalyst was washed with clean water.

[0038](4) Roasting: place the catalyst obtained in step (3) in an oven at 120 °C for 2.5 hours, then move it to a muffle furnace for roasting at 480 °C for 5 hours, and place the roasted catalyst in a desiccator for natural cooling to obtain the iron-manganese-cobalt co-doped supported Fenton catalyst.

Embodiment 3

[0040] (1) Carrier pretreatment: TiO with a particle size of 2 to 4 mm 2 -Al 2 O 3 The carrier is decontaminated and dried.

[0041] (2) Preparation of impregnation solution: preparation of Fe 3+ , Mn 2+ and Co 2+ Fe(NO) with a molar concentration ratio of 1:1:1 3 ) 3 ·9H 2 O, Mn (NO 3 ) 2 ·4H 2 O, CoCl 2 ·6H 2 Aqueous O solution, adjusted to pH 7.0 with NaOH.

[0042] (3) Impregnation: the pretreated TiO 2 -Al 2 O 3 The carrier is completely immersed in the prepared immersion solution, stirred slowly at a constant speed, fully immersed for 14 hours, filtered after the immersion is completed, and the catalyst is washed with clean water.

[0043] (4) Roasting: the catalyst obtained in step (3) was placed in an oven to be dried at 122°C for 2 hours, then moved to a muffle furnace for calcination at 500°C for 4.5 hours, and the roasted catalyst was placed in a desiccator for natural cooling to obtain the iron-manganese-cobalt co-doped supported Fenton catalyst. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com