Preparation method for alternating multilayer microporous silicone rubber foam material

A foam material and silicone rubber technology, which is applied in the field of preparation of alternate multi-layer microporous silicone rubber foam materials, can solve the problems of compatibility and processing conditions affecting the actual performance of composite materials, and achieve high compression resistance and improved compression strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of alternating multilayer microporous silicone rubber foam material, comprising the following steps:

[0032] (1) Preparation of silicone rubber compound

[0033] The distribution ratio of each component of silicone rubber A is: 100 parts of methyl vinyl silicone rubber, 40 parts of fumed silica, 8 parts of hydroxyl silicone oil, and 1 part of vulcanizing agent dicumyl peroxide;

[0034] The distribution ratio of each component of silicone rubber B is: 100 parts of methyl vinyl silicone rubber, 40 parts of precipitated silica, 4 parts of hydroxyl silicone oil, and 1 part of dicumyl peroxide;

[0035] (2) Preparation of multilayer silicone rubber composites

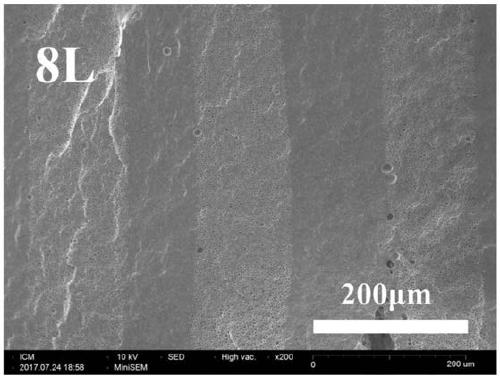

[0036] The temperature of each section of the two extruders of the alternating multi-layer co-extrusion equipment is about 80°C, and the speed ratio is 1:1, and an 8-layer silicone rubber alternating multi-layer composite material is prepared, and its size is about 500×50×2mm 3 ;

[0037] (3)...

Embodiment 2

[0044] (1) Preparation of silicone rubber compound

[0045] The distribution ratio of each component of silicone rubber A is: 100 parts of methyl vinyl silicone rubber, 50 parts of fumed silica, 8 parts of hydroxyl silicone oil, 1 part of vulcanizing agent dicumyl peroxide; the distribution of each component of silicone rubber B The ratio is: 100 parts of methyl vinyl silicone rubber, 50 parts of precipitated silica, 4 parts of hydroxyl silicone oil, and 1 part of dicumyl peroxide;

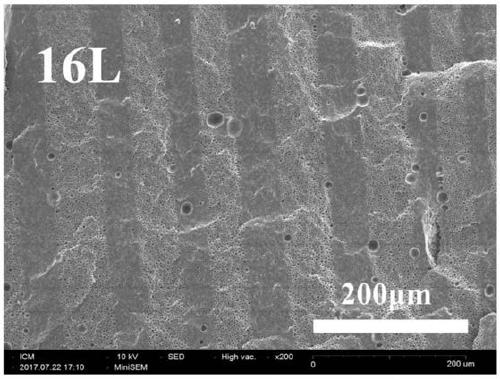

[0046] (2) Preparation of multilayer silicone rubber composites

[0047] The temperature of each section of the two extruders of the alternating multi-layer co-extrusion equipment is about 80°C, and the speed ratio is 2:3. A 16-layer silicone rubber alternating multi-layer composite material is prepared, and its size is about 500×50×2mm 3 ;

[0048](3) Preparation of multi-layer silicone rubber samples to be foamed

[0049] The length x width x thickness is 40 x 30 x 2mm 3 The multi-layer sili...

Embodiment 3

[0055] (1) Preparation of silicone rubber compound

[0056] The distribution ratio of each component of silicone rubber A is: 100 parts of methyl vinyl silicone rubber, 40 parts of fumed silica, 8 parts of hydroxyl silicone oil, 1 part of vulcanizing agent dicumyl peroxide; the distribution of each component of silicone rubber B The ratio is: 100 parts of methyl vinyl silicone rubber, 40 parts of precipitated silica, 4 parts of hydroxyl silicone oil, and 1 part of dicumyl peroxide;

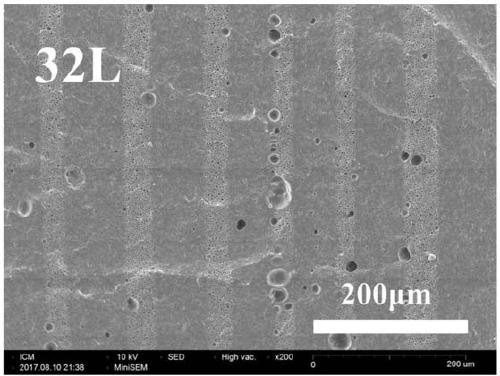

[0057] (2) Preparation of multilayer silicone rubber composites

[0058] The temperature of each section of the two extruders of the alternating multi-layer co-extrusion equipment is about 80°C, and the speed ratio is 2:1. A 32-layer silicone rubber alternating multi-layer composite material is prepared, and its size is about 500×50×2mm 3 ;

[0059] (3) Preparation of multi-layer silicone rubber samples to be foamed

[0060] The length x width x thickness is 40 x 30 x 2mm 3 The multi-layer sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com