Anti-ultraviolet thermal shrinkage film

A heat-shrinkable film and anti-ultraviolet technology, which is applied in the direction of flexible coverings, types of packaging items, special packaging items, etc., can solve problems such as not having anti-ultraviolet properties, affecting drug properties, endangering the life safety and health of patients, and achieving the goal of manufacturing The effect of low cost, guaranteed quality and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

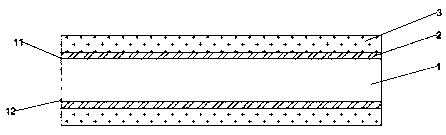

[0021] see figure 1 , in the embodiment of the present invention, an anti-ultraviolet heat-shrinkable film includes a heat-shrinkable film 1, an adhesive layer 2 and an anti-ultraviolet coating layer 3, and the heat-shrinkable film 1 has an upper surface 11 and a lower surface 12 up and down, so The side of the upper surface 11 and the lower surface 12 away from the heat shrinkable film 1 is bonded with an adhesive layer 2, and the side of the adhesive layer 2 away from the upper surface 11 and the lower surface 12 is bonded with an anti-ultraviolet coating layer 3. The upper surface 11 and the lower surface 12 have the same thickness, and the thickness of the upper surface 11 and the lower surface 12 is 1 μm.

[0022] The heat-shrinkable film 1 is an OPP heat-shrinkable film, and the thickness of the heat-shrinkable film 1 is 20 μm.

[0023] The adhesive layer 2 includes the following raw materials in parts by weight: 10 parts of talcum powder, 5 parts of titanium dioxide, 8...

Embodiment 2

[0031] see figure 1 , in the embodiment of the present invention, an anti-ultraviolet heat-shrinkable film includes a heat-shrinkable film 1, an adhesive layer 2 and an anti-ultraviolet coating layer 3, and the heat-shrinkable film 1 has an upper surface 11 and a lower surface 12 up and down, so The side of the upper surface 11 and the lower surface 12 away from the heat shrinkable film 1 is bonded with an adhesive layer 2, and the side of the adhesive layer 2 away from the upper surface 11 and the lower surface 12 is bonded with an anti-ultraviolet coating layer 3. The upper surface 11 and the lower surface 12 have the same thickness, and the thickness of the upper surface 11 and the lower surface 12 is 2 μm.

[0032] The heat-shrinkable film 1 is a PET heat-shrinkable film, and the thickness of the heat-shrinkable film 1 is 60 μm.

[0033] The adhesive layer 2 includes the following raw materials in parts by weight: 20 parts of talcum powder, 12 parts of titanium dioxide, 1...

Embodiment 3

[0041] see figure 1 , in the embodiment of the present invention, an anti-ultraviolet heat-shrinkable film includes a heat-shrinkable film 1, an adhesive layer 2 and an anti-ultraviolet coating layer 3, and the heat-shrinkable film 1 has an upper surface 11 and a lower surface 12 up and down, so The side of the upper surface 11 and the lower surface 12 away from the heat shrinkable film 1 is bonded with an adhesive layer 2, and the side of the adhesive layer 2 away from the upper surface 11 and the lower surface 12 is bonded with an anti-ultraviolet coating layer 3. The upper surface 11 and the lower surface 12 have the same thickness, and the thickness of the upper surface 11 and the lower surface 12 is 1.2 μm.

[0042] The heat-shrinkable film 1 is an OPP heat-shrinkable film, and the thickness of the heat-shrinkable film 1 is 30 μm.

[0043] The adhesive layer 2 includes the following raw materials in parts by weight: 12 parts of talcum powder, 6 parts of titanium dioxide,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com