Method for preparation cesium sulfate from salt-containing wastewater

A technology of saline wastewater and cesium sulfate, which is applied in the direction of improving process efficiency, etc., can solve the problems that the separation effect cannot be achieved, BAMBP cannot be mass-produced, and the price is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

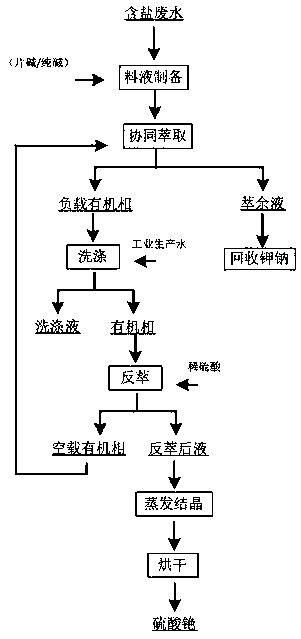

[0030] Such as figure 1 Shown, a method for preparing cesium sulfate in saline waste water, comprises the following steps:

[0031] The first step, prepare extractant, take t-BAMBP, P 204 and kerosene, the t-BAMBP, P 204 Mixed with kerosene to obtain extractant;

[0032] The second step is to detect the ion concentration of the feed liquid, and detect the Cs in the saline wastewater by atomic absorption spectrometry + , Rb + 、K + and Na + concentration;

[0033] The third step is to take the saline wastewater to adjust the pH, and use alkaline substances to adjust the pH value of the saline wastewater to obtain the feed liquid;

[0034] In the fourth step, the post-extractant is subjected to multi-stage countercurrent extraction of the feed liquid to obtain a loaded organic phase;

[0035] In the fifth step, the loaded organic phase is circulated and countercurrently washed with the washing liquid to obtain the loaded organic phase after washing;

[0036] The 6th step...

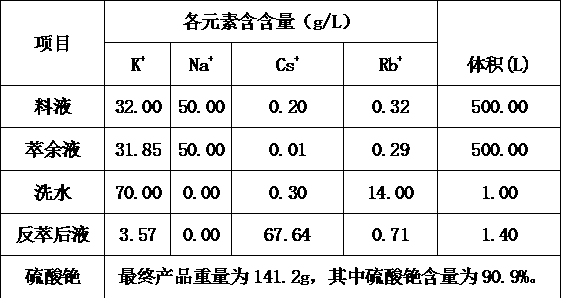

Embodiment 2

[0041] A method for preparing cesium sulfate in saline waste water, comprising the following steps:

[0042] The first step, prepare extractant, take t-BAMBP, P 204 and kerosene, the t-BAMBP, P 204 Mix with kerosene to obtain extractant, t-BAMBP is 15 parts by weight, P 204 5 parts for kerosene and 75 parts for kerosene;

[0043] The second step is to detect the ion concentration of the feed liquid, and detect the Cs in the saline wastewater by atomic absorption spectrometry + , Rb + 、K + and Na + Concentration, Cs + The concentration is 0.1g / L, Rb + The concentration is 0.2g / L, K + The concentration is 25g / L, Na + The concentration is 30g / L;

[0044] The third step is to take the saline wastewater to adjust the pH, and use alkaline substances to adjust the pH value of the saline wastewater to obtain a feed liquid, wherein the alkaline substances are sodium carbonate, sodium hydroxide, and liquid caustic soda, and the pH is adjusted to > 13. The addition method inclu...

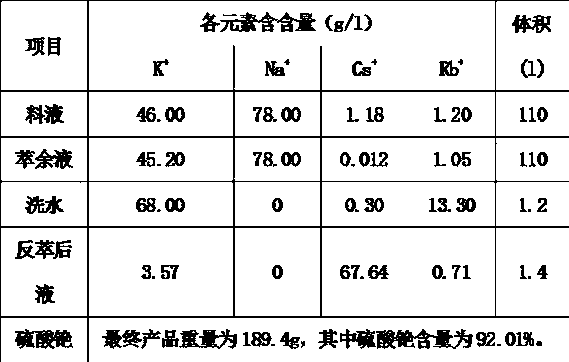

Embodiment 3

[0052] A method for preparing cesium sulfate in saline waste water, comprising the following steps:

[0053] The first step, prepare extractant, take t-BAMBP, P 204 and kerosene, the t-BAMBP, P 204 Mix with kerosene to obtain extractant, t-BAMBP is 20 parts by weight, P 204 5 parts for kerosene and 80 parts for kerosene;

[0054] The second step is to detect the ion concentration of the feed liquid, and detect the Cs in the saline wastewater by atomic absorption spectrometry + , Rb + 、K + 、Na + Concentration, Cs + The concentration is 1.2g / L, Rb + The concentration is 1.2g / L, K + The concentration is 45g / L, Na + The concentration is 80g / L;

[0055] The third step is to take the saline wastewater to adjust the pH, and use alkaline substances to adjust the pH value of the saline wastewater to obtain a feed liquid, wherein the alkaline substances are sodium carbonate, sodium hydroxide, and liquid caustic soda, and the pH is adjusted to > 13. The addition method includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com