Hyaluronic acid silk fabric and making method thereof

A production method and technology of hyaluronic acid, applied in the field of silk fabrics, can solve problems such as unfavorable environmental protection, unfavorable direct skin contact, etc., and achieve the effects of maintaining moisturizing and diluting fine lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for making a hyaluronic acid silk fabric, comprising the steps of:

[0028] (1) Take the silk fabric that has completed the dyeing process, dry and roll it, then paddle hyaluronic acid, and add a working solution to the finishing machine. The working solution is composed of a softener, a color fixing agent and a hyaluronic acid finishing agent. Through the working liquid in the finishing machine at a high speed, the method of dipping and rolling is adopted, and the liquid retention rate is 100%, so that the hyaluronic acid molecules are fully attached to the silk fiber;

[0029] (2) The silk fabric after padding is dried by a dryer, and antistatic treatment is carried out by spraying with an antistatic finishing agent at the same time. 115°C, the speed of silk fabric passing through the dryer is 17m / min;

[0030] (3) The dried silk fabric is rolled.

[0031] In the working solution, the bath ratio of the softener is 5%, the bath ratio of the color fixing agen...

Embodiment 2

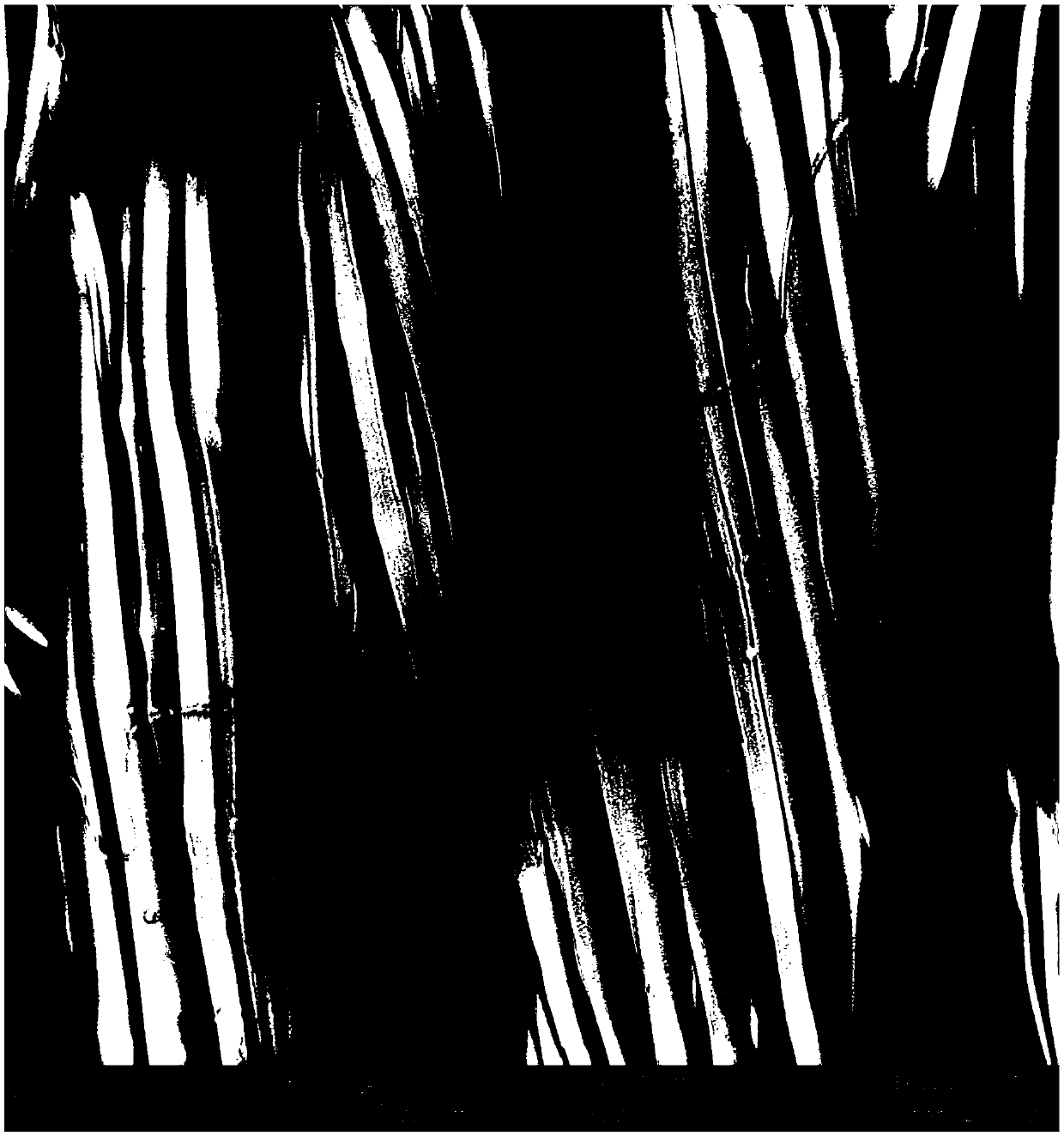

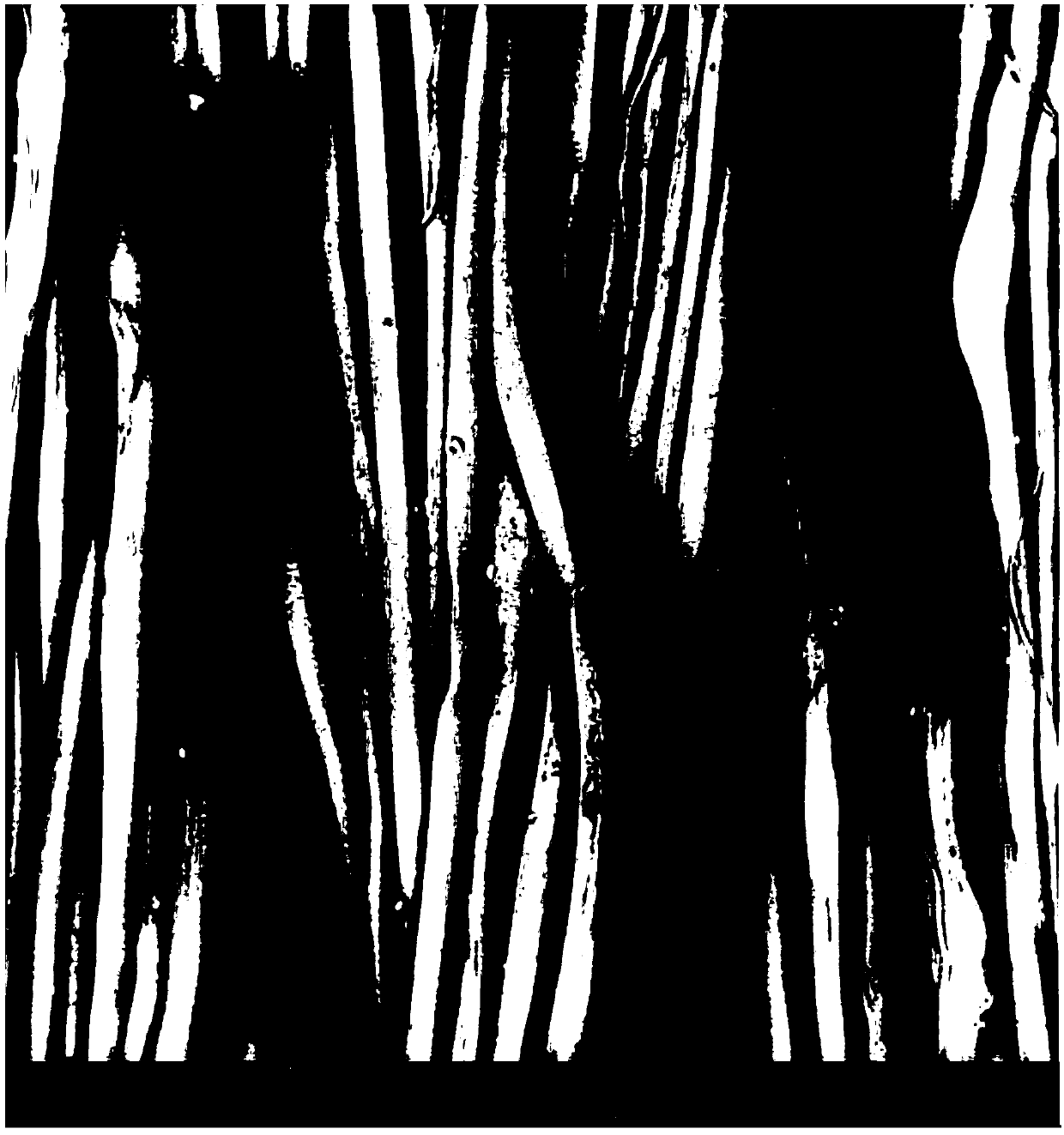

[0040] The silk fabrics of embodiment 1 and comparative example 1 are carried out electron microscope scanning respectively, obtain as follows Figure 1-2 scanning electron microscope image. Depend on Figure 1-2 It can be clearly seen that the hyaluronic acid micelles are evenly distributed on the silk fibers after the silk fabric in Example 1 is padded with the working solution. The process makes it attached to the silk fiber.

[0041] After the silk fabric that embodiment 1 is obtained is washed 15 times, then scan with electron microscope, obtain such as image 3 scanning electron microscope image. Depend on image 3 It can be seen that the hyaluronic acid micelles can still be distributed on the silk fiber after the silk fabric of the present invention is washed 15 times. Therefore, the silk fabric of the present invention can still maintain the hyaluronic acid attached to the silk fabric after washing, and has better washability.

[0042] The silk fabrics of Exampl...

Embodiment 3

[0051] A method for making a hyaluronic acid silk fabric, comprising the steps of:

[0052] (1) Take the silk fabric that has completed the dyeing process, dry and roll it, then paddle hyaluronic acid, and add working fluid into the finishing machine. The working fluid is composed of softener, color fixing agent and hyaluronic acid finishing agent. Through the working liquid in the finishing machine at a high speed, the method of dipping and rolling is adopted, and the liquid retention rate is 100%, so that the hyaluronic acid molecules are fully attached to the silk fiber;

[0053] (2) The silk fabric after padding is dried by a dryer, and antistatic treatment is carried out by spraying with an antistatic finishing agent at the same time. 100℃, the speed of silk fabric passing through the dryer is 16m / min;

[0054] (3) The dried silk fabric is rolled.

[0055] In the working liquid, the bath ratio of the softening agent is 3%, the bath ratio of the color fixing agent is 4.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com