Atmospheric pressure coal-fired boiler with desulfurization, denitrification and dust removal in furnace and its treatment method

A technology for desulfurization, denitrification, and boilers, which is applied to atmospheric pressure coal-fired boilers for desulfurization, denitrification and dust removal in the furnace and its treatment field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

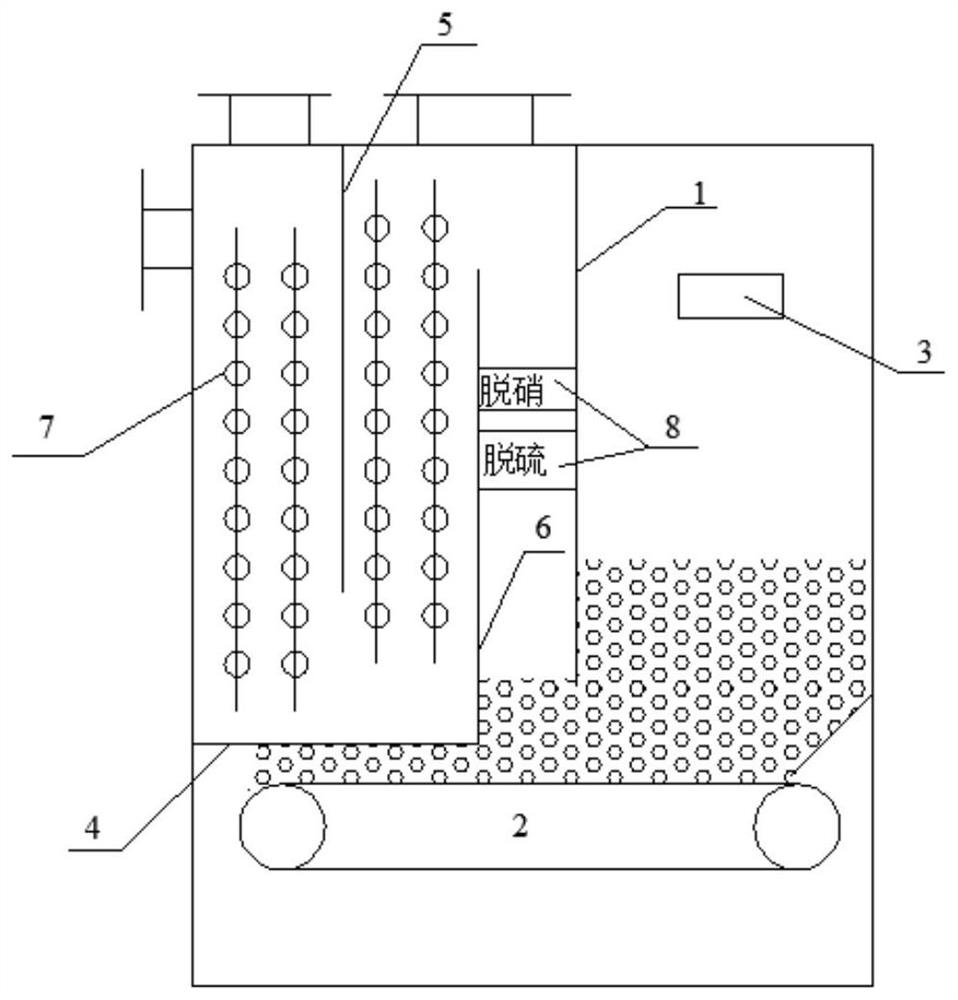

[0055] This embodiment provides a kind of normal pressure water heating boiler, such as figure 1 As shown, the atmospheric pressure water heating boiler is longitudinally provided with a first longitudinal partition 1 at the top of the furnace body, and the furnace body is divided into a first chamber and a second chamber connected at the bottom, and the first chamber and the second chamber A chain grate 2 is provided at the lower part of the first chamber, a coal filling port 3 is provided on the furnace wall on one side of the first chamber, and a first transverse partition 4 connected to the furnace wall is arranged above the chain grate 2 in the second chamber. There is a gap between the transverse partition 4 and the first longitudinal partition 1, and a second longitudinal partition 5 is longitudinally arranged on the top furnace wall in the second chamber, and the second longitudinal partition 5 is connected to the first transverse partition. There is a gap between the ...

Embodiment 2

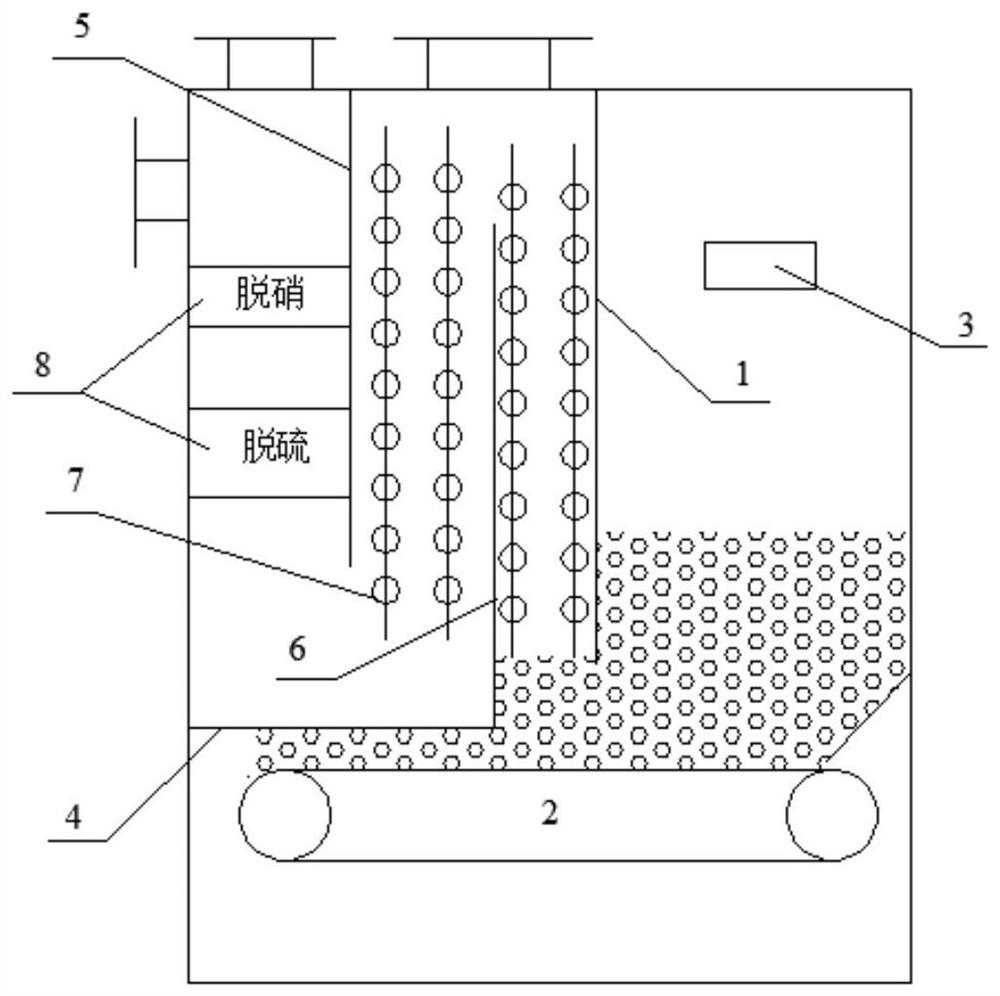

[0061] This embodiment provides a kind of normal pressure water heating boiler, such as figure 2 As shown, the atmospheric pressure water heating boiler is longitudinally provided with a first longitudinal partition 1 at the top of the furnace body, and the furnace body is divided into a first chamber and a second chamber connected at the bottom, and the first chamber and the second chamber A chain grate 2 is provided at the lower part of the first chamber, a coal filling port 3 is provided on the furnace wall on one side of the first chamber, and a first transverse partition 4 connected to the furnace wall is arranged above the chain grate 2 in the second chamber. There is a gap between the transverse partition 4 and the first longitudinal partition 1, and a second longitudinal partition 5 is longitudinally arranged on the top furnace wall in the second chamber, and the second longitudinal partition 5 is connected to the first transverse partition. There is a gap between the...

Embodiment 3

[0067] This embodiment provides an atmospheric pressure water heating boiler. The structure of the atmospheric pressure water heating boiler refers to the structure in Example 1, the only difference is that one second longitudinal partition 5 and two third longitudinal partitions are arranged in the furnace body. The partition 6 forms a flue gas circulation area including four return paths in the second chamber.

[0068] The atmospheric pressure hydrothermal boiler is used for flue gas treatment, and the treatment method refers to the method in Example 1.

[0069] In this embodiment, NO in the flue gas discharged from the furnace x Concentration less than 100mg / Nm 3 , the sulfur concentration is less than 50mg / Nm 3 , its desulfurization efficiency reaches 90%, denitrification efficiency reaches 50%, and dust removal efficiency reaches 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com