Optical Fiber Automatic Test System Based on Industrial Internet Platform

An automatic test system and industrial Internet technology, applied in the field of industrial Internet, can solve problems such as test data errors, and achieve the effect of reducing computing pressure, reducing costs, and realizing hardware isolation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] The embodiment proposes an automatic optical fiber test system based on an industrial Internet platform, and the specific implementation methods are as follows:

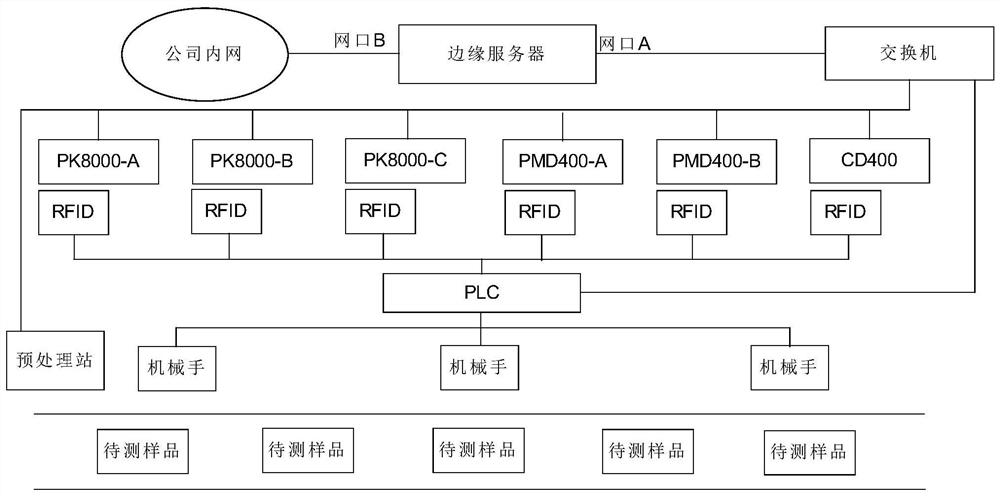

[0031] see figure 1 , the optical fiber automatic test system based on the industrial Internet platform includes:

[0032] The pretreatment station puts the optical fiber samples into trays with RFID tags; the transmission line is used to carry the samples to be tested (including trays); the manipulator is used to transport the samples to be tested (including trays) to the corresponding testing equipment, and the test The completed samples (including trays) are taken from the test equipment and put back into the transportation line; RFID read-write heads are installed at each test equipment to read the label information on the trays; PLC collects data from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com