A design method of stress compensation film for AT-cut temperature compensated crystal oscillator

A stress compensation and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as high cost and complex processing, and achieve the effect of solving cost problems, strong operability, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] One can avoid the error caused by adjusting and compensating the shape and position of the film according to manual experience, and can solve the actual processing cost, and has strong operability. A stress compensation film design method for AT-cut temperature-compensated crystal oscillators has practical significance for the design and development of high-stability temperature-compensated crystal oscillators.

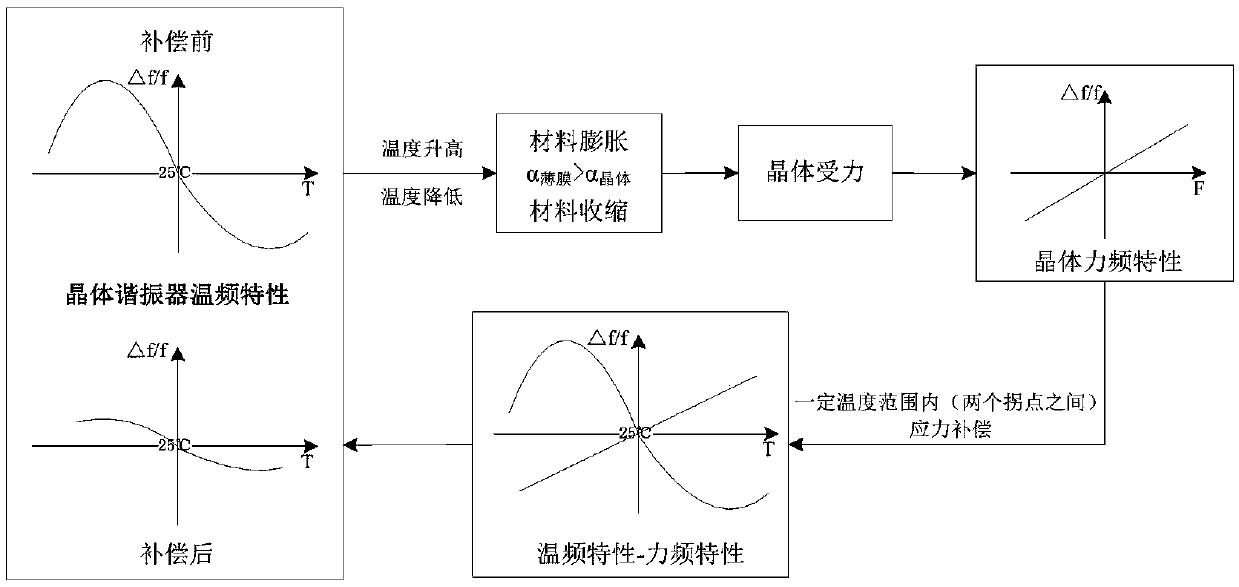

[0030] Such as figure 1 As shown, the temperature-frequency characteristic curve of the AT-cut crystal is a cubic function curve, and the force-frequency characteristic curve has a good linear relationship. By coating a layer of metal film with different thermal expansion coefficients on the crystal surface, when the temperature rises or falls, the film and Thermal stress is generated between the crystals, and the force-frequency characteristics pull the temperature-frequency curve, so that the temperature-frequency characteristics of the crystals are improved....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com