Foam-medium-based metamaterial with wide-band electromagnetic wave absorption

A foam material and metamaterial technology, applied in the field of foam dielectric-based metamaterials, can solve the problems of narrow frequency band and high density of wave absorbing materials, and achieve the effect of simple structure and good radar absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

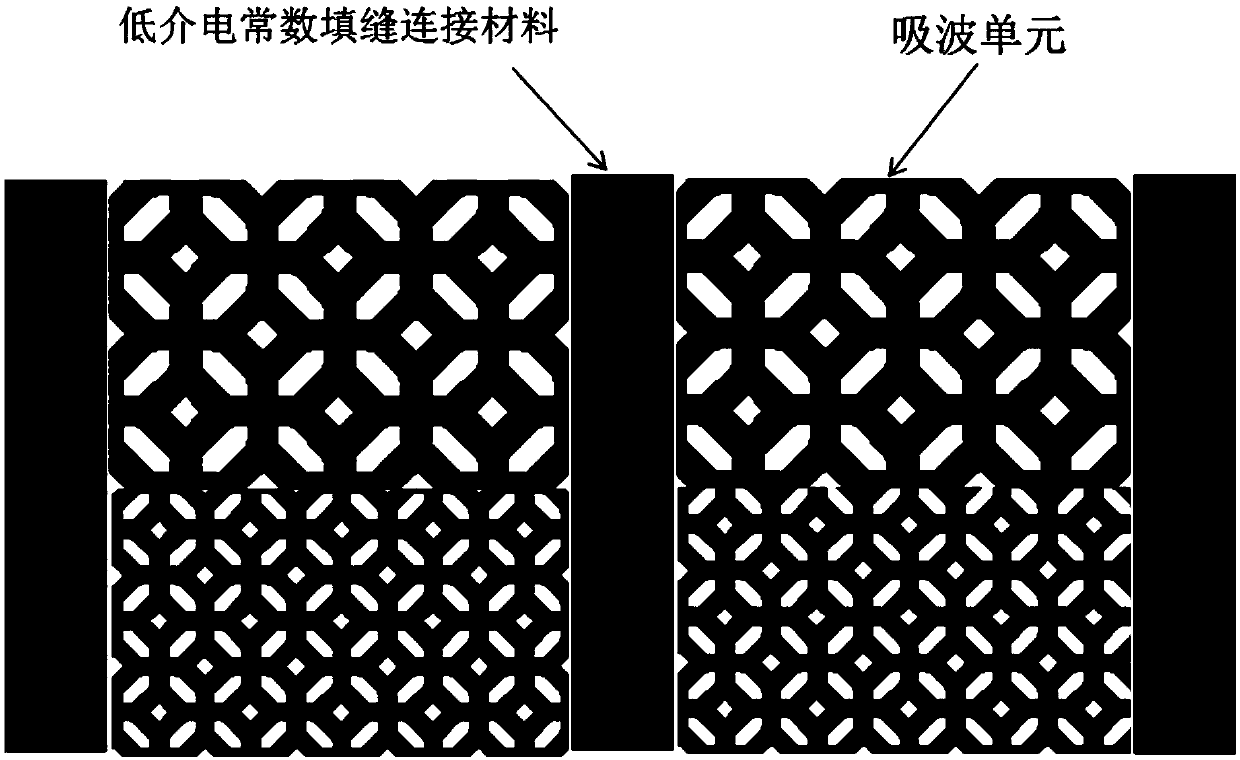

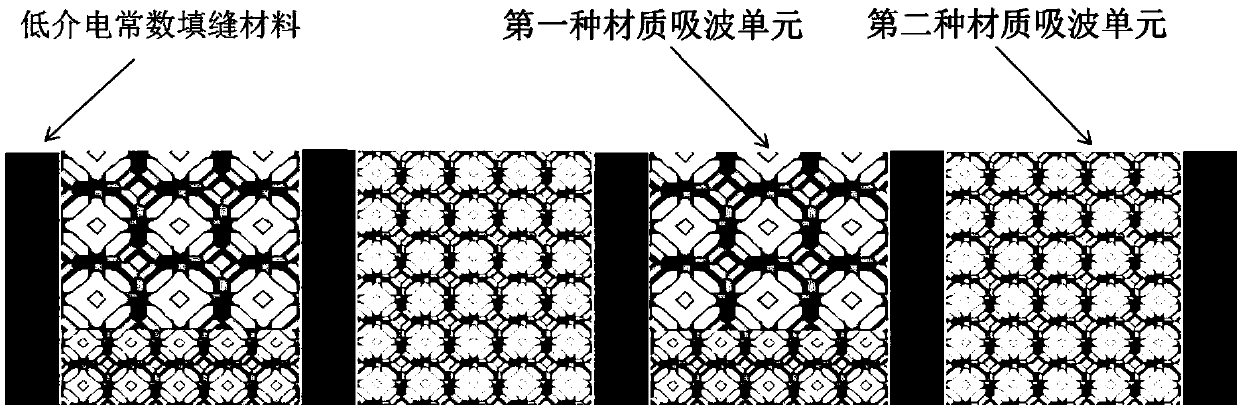

Embodiment 1

[0035] It consists of a material absorbing unit, and the combined material is carbon foam. Select a foam board with a mesh aperture of 1mm, an electrical conductivity of 0.7s / m-1s / m, and a thickness of 200mm, and process it into a square foam block of 20×20×6mm as the bottom layer material; Foam board with conductivity 0.6s / m, 200×200mm, plate thickness 20mm, processed into 20×20×4mm square foam block as the middle layer material; select mesh aperture 2mm, conductivity 0.2s / m, 200×200mm The foam board, with a thickness of 20mm, is processed into 20×20×4mm square foam pieces as the material for the incoming wave layer; several small pieces are bonded with a thin layer of epoxy resin less than 0.2mm, and each connected small piece The block is wrapped with a polyimide film with a thickness of 2 μm, and the foam block is glued to the bottom plate with epoxy resin, and the distance between the foam block is 3 mm, and put into the mold. The weight percentage is 88wt%: 2wt%: 10wt% ...

Embodiment 2

[0038] It is composed of a material absorbing unit, and the combined material is silicon carbide foam. Choose mesh aperture 4mm, resistivity 10 3 -10 10 Ω·m, 200×200mm foam board, 20mm thick; processed into 60×60×15mm square foam small pieces, each small piece is wrapped with a polyimide film with a thickness of 3μm, and the foam piece is covered with epoxy resin Stick to the bottom plate, the foam block spacing is 20mm, put into the mold. The weight percentage is 80wt%: 2wt%: 18wt% phenolic resin, p-toluenesulfonic acid and hollow glass microspheres with a particle size of 5-10 μm are mixed, and the mixture is filled in the gaps between the foams, and the mixture is combined with the above foam Completing hot-compression compounding in the mold, the compounding conditions are temperature control at 80°C and pressure at 8 MPa for 3 hours.

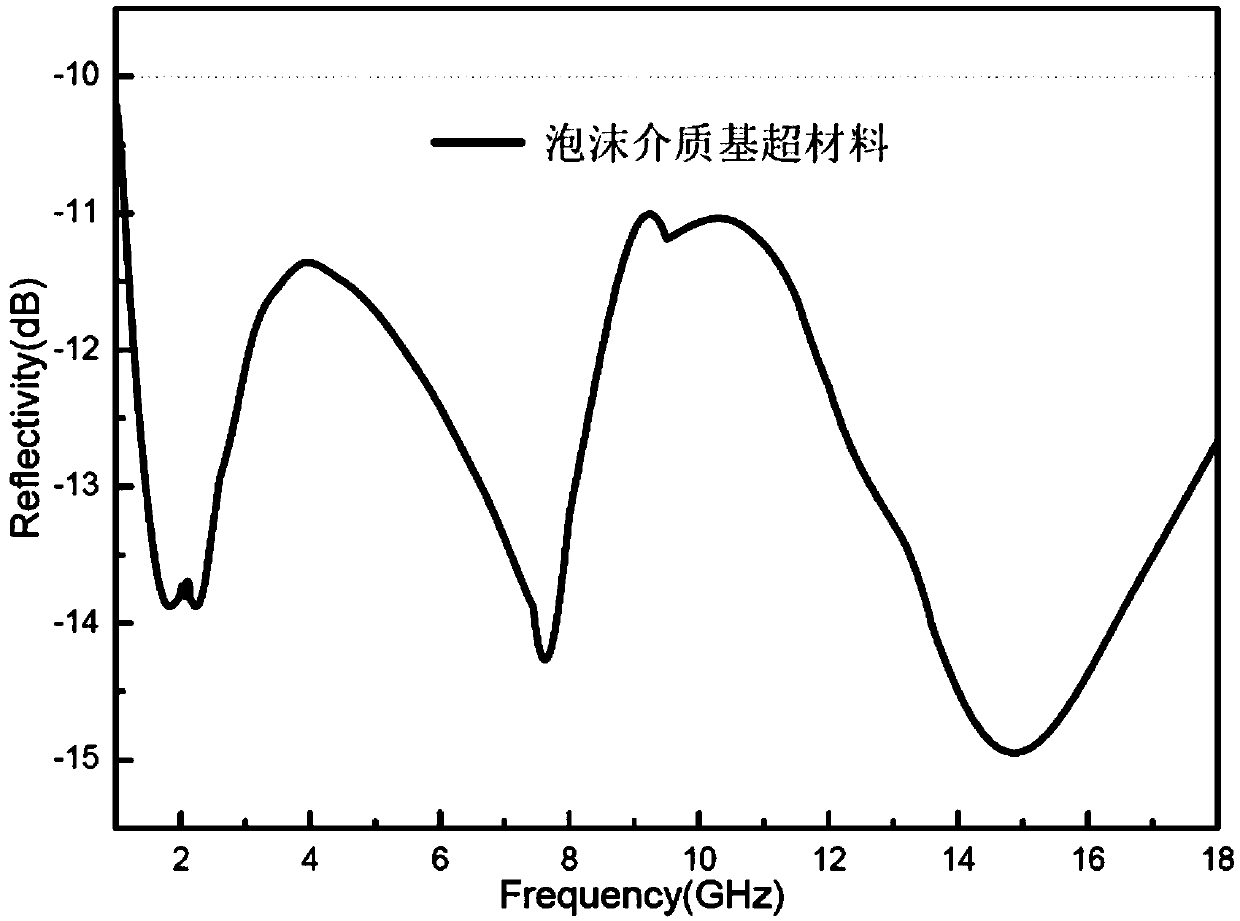

[0039] On the Agilent-N5230A network analyzer, the time domain test method is used to test the reflectivity of the flat panel. In this ...

Embodiment 3

[0041] It consists of a group of wave-absorbing units, and the combined material is foamed sendust. Select a foam board with a mesh aperture of 2 mm, a particle size of 80 μm, and a thickness of 200 mm, with a thickness of 20 mm; process it into a square foam block of 30 × 30 × 15 mm, and cover each small block with a polyimide film with a thickness of 5 μm For wrapping, glue the foam blocks to the bottom plate with epoxy resin, the distance between the foam blocks is 5mm, and put them into the mold. The weight percentage is 80wt%: 2wt%: 18wt% phenolic resin, p-toluenesulfonic acid and hollow glass microspheres with a particle size of 5-10 μm are mixed, and the mixture is filled in the gaps between the foams, and the mixture is combined with the above foam Completion of hot-compression lamination in the mold, the lamination conditions are temperature control 70 ℃, 7MPa pressure for 6 hours.

[0042] On the Agilent-N5230A network analyzer, the time domain test method is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com