Ankle exercising device

An exercise device and ankle technology, applied in sports accessories, muscle training equipment, gymnastics equipment, etc., can solve problems such as time-consuming and labor-consuming, excessive wear of components, and failure to achieve exercise effects, etc., to reduce wear and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

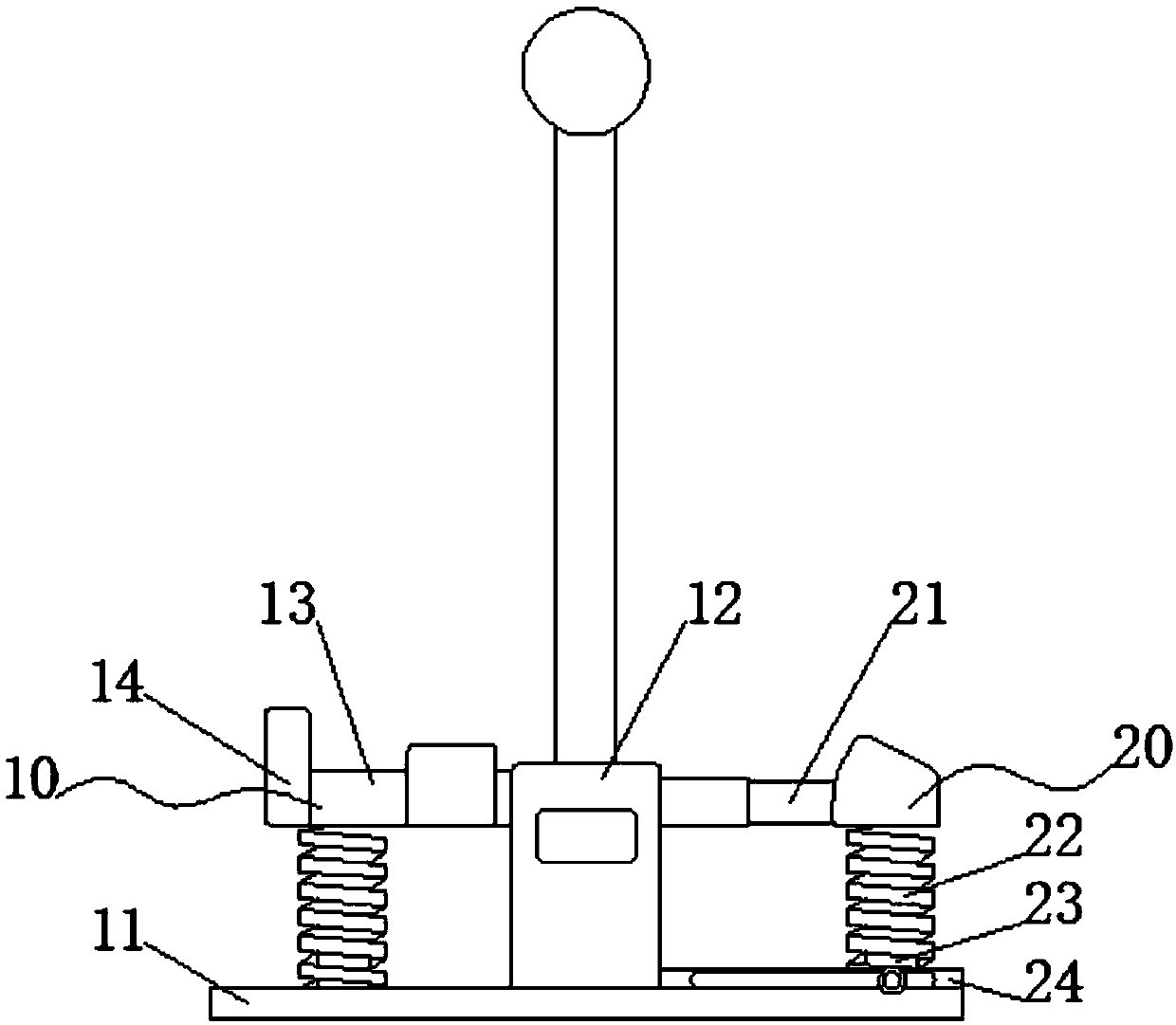

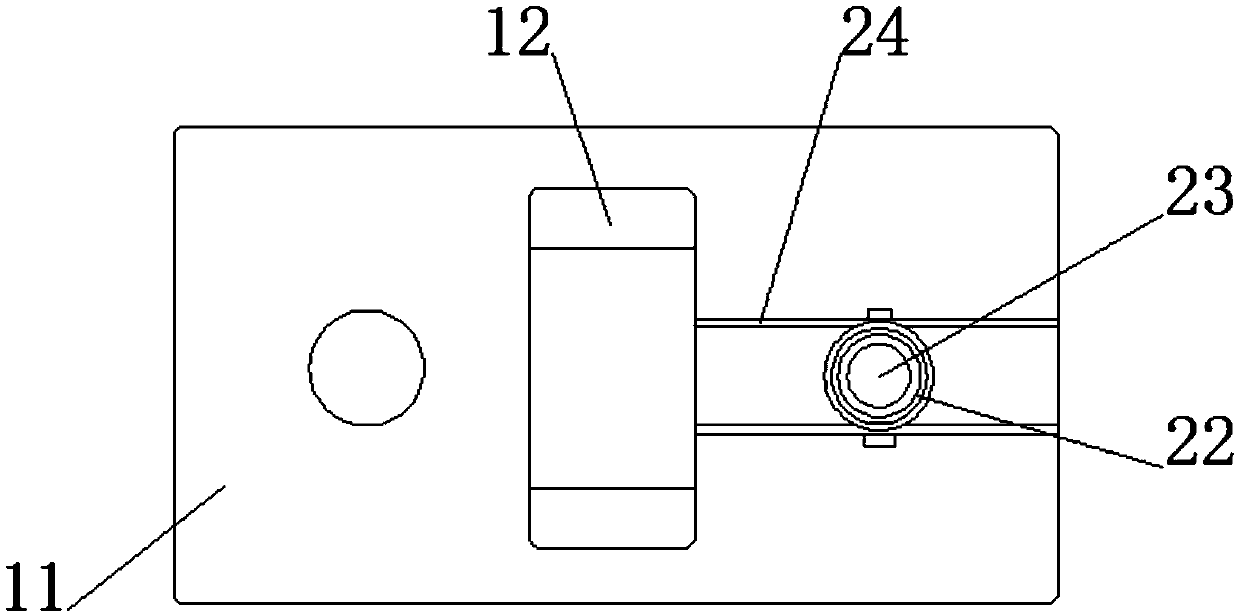

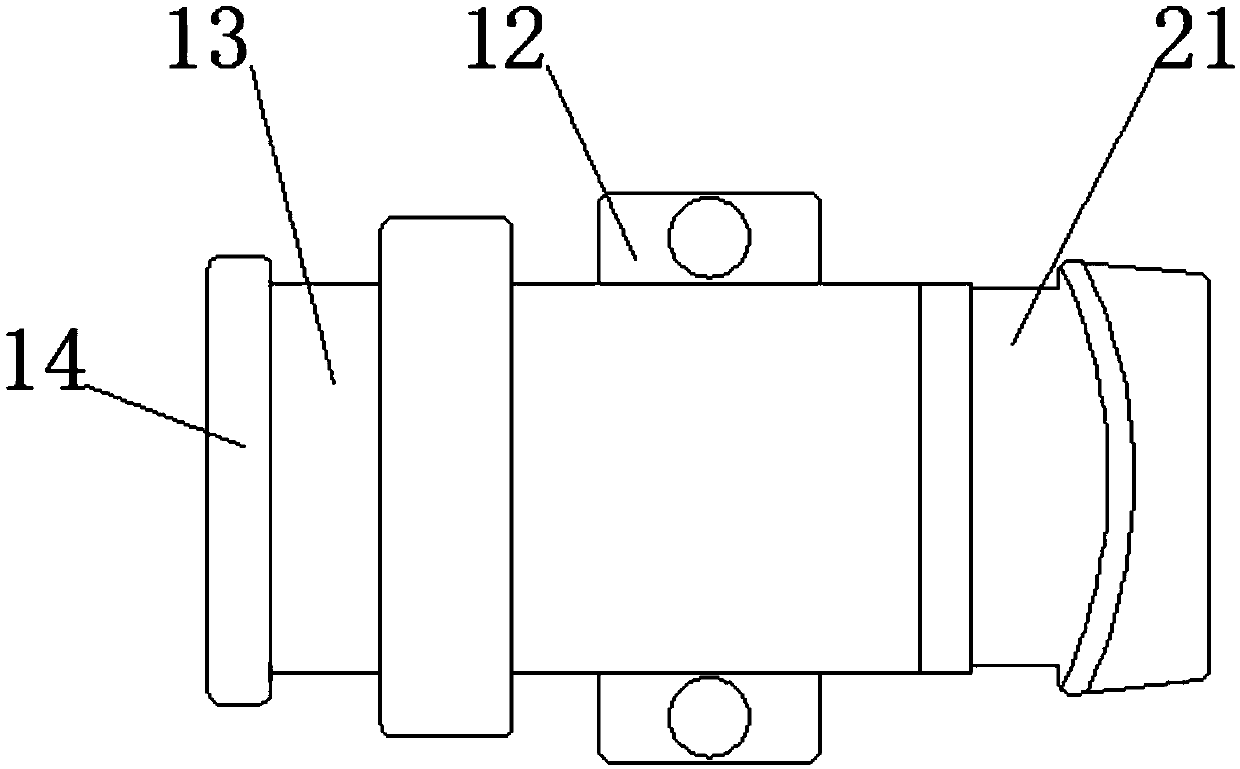

[0026] see Figure 1-4 , the present invention provides a technical solution: an ankle exercise device, including a support assembly 10 and a sliding assembly 20, the support assembly 10 includes a base 11, a connecting plate 12, a first pedal 13 and a fixing part 14, the upper surface of the base 11 is provided with There is a connection plate 12, the connection plate 12 is fixedly connected with the base 11, the inner side wall of the connection plate 12 is provided with a first pedal 13, the first pedal 13 is fixedly connected with the connection plate 12, the fixed part 14 is located at the left end of the first pedal 13, and Fixedly connected with the first pedal 13, the sliding assembly 20 includes a second pedal 21, a spring 22, a mounting block 23 and a sliding part 24, the second pedal 21 is located on the inner side wall of the first pedal 13, and is slidably connected with the first pedal 13, The spring 22 is located at the bottom of the second pedal 21 and is fixed...

Embodiment 2

[0039] The difference from Example 1 is that the surface of the sliding assembly 20 is coated with a wear-resistant layer, and the preparation method of the wear-resistant layer is as follows:

[0040] Get the following components by weight for subsequent use: 20 parts of vinyl ester resin, 3 parts of calcium carbonate, 5 parts of deionized water, 3 parts of epoxy soybean oil, 10 parts of acetylcholine, 1.4 parts of hydroxyethyl cellulose, diatom 15 parts of soil, 7 parts of aluminum hydroxide, 9 parts of acrylic emulsion.

[0041] S1. Prefabricated organic solvent: mix vinyl ester resin, epoxidized soybean oil, and acrylic acid emulsion, heat to 58°C, stir evenly, and keep warm for 3 hours;

[0042]S2. Preparation of wear-resistant coating: Add aluminum hydroxide, hydroxyethyl cellulose, calcium carbonate, diatomaceous earth, acetylcholine, and deionized water to the organic solvent in S1 in sequence, and after stirring evenly, heat the temperature to 72°C Post-insulation fo...

Embodiment 3

[0048] The difference from Example 2 is that the formula specific gravity of the wear-resistant layer is modified and recoated on the sliding assembly 20:

[0049] Get the following components by weight for subsequent use: 30 parts of vinyl ester resin, 5 parts of calcium carbonate, 9 parts of deionized water, 7 parts of epoxy soybean oil, 15 parts of acetylcholine, 1.6 parts of hydroxyethyl cellulose, diatom 20 parts of soil, 10 parts of aluminum hydroxide, 13 parts of acrylic emulsion.

[0050] S1. Prefabricated organic solvent: mix vinyl ester resin, epoxidized soybean oil, and acrylic acid emulsion, heat to 58°C, stir evenly, and keep warm for 3 hours;

[0051] S2. Preparation of wear-resistant coating: Add aluminum hydroxide, hydroxyethyl cellulose, calcium carbonate, diatomaceous earth, acetylcholine, and deionized water to the organic solvent in S1 in sequence, and after stirring evenly, heat the temperature to 72°C Post-insulation for 1h;

[0052] S3, processing: ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com