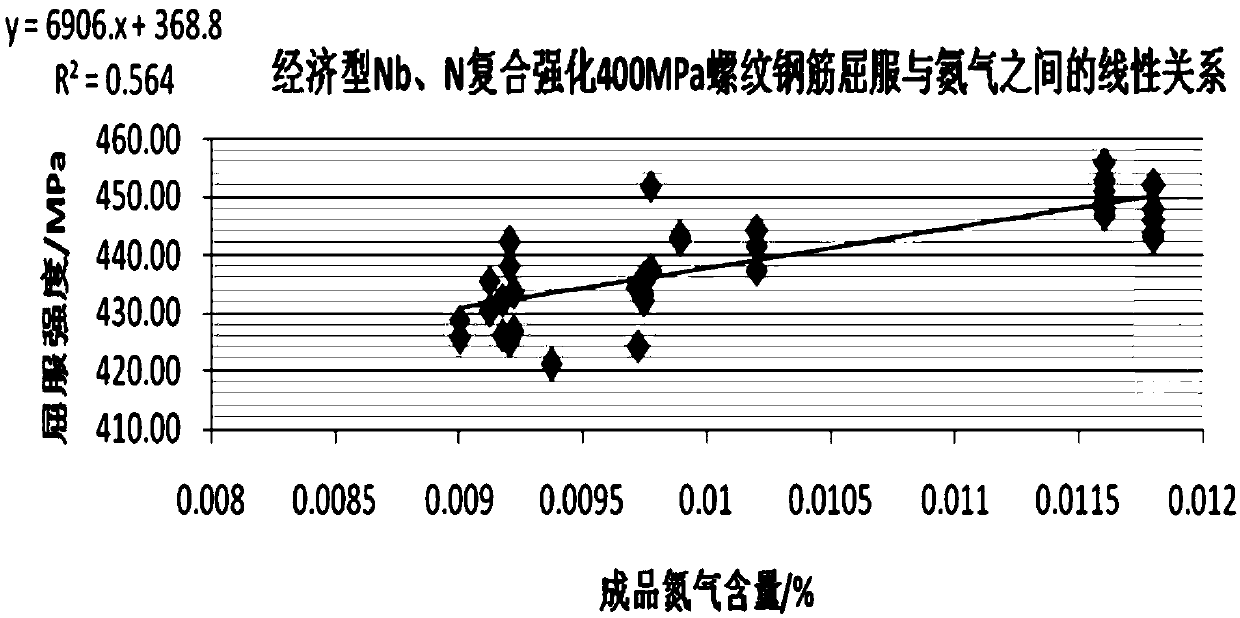

Nb and N composite reinforced 400 MPa grade steel bar and manufacturing method thereof

A manufacturing method and a technology for graded steel bars, which are applied in the field of hot-rolled ribbed steel bar rolling, can solve problems such as low production efficiency and slow rolling speed, and achieve the effect of ensuring high efficiency and economical manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

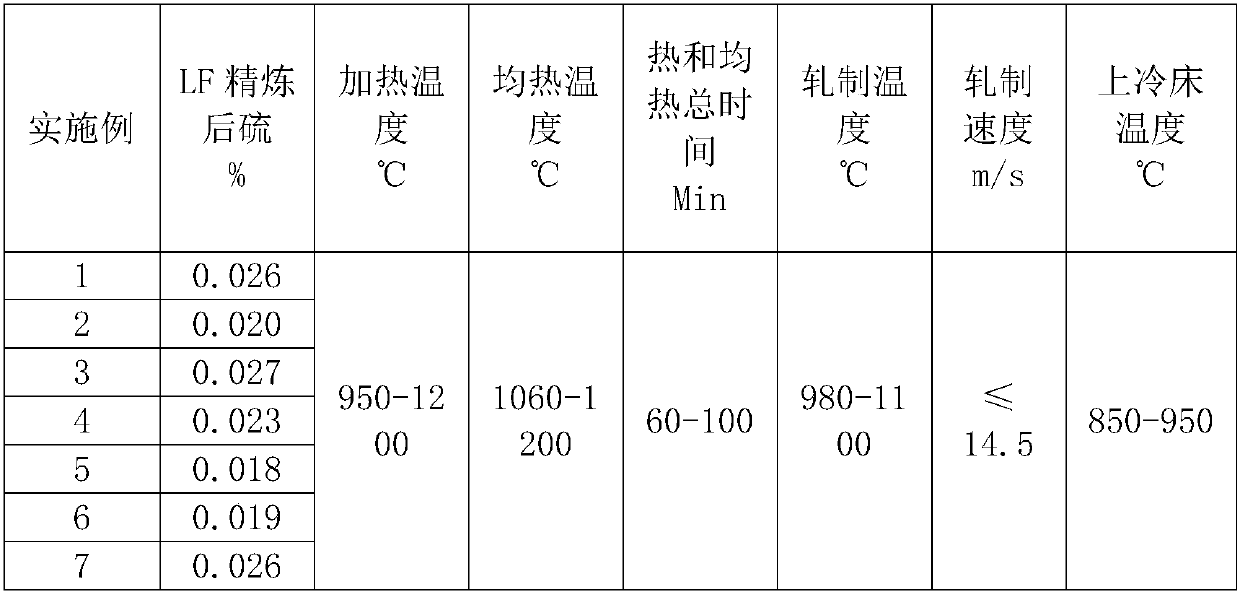

Embodiment 1-7

[0036] The production procedure that present embodiment adopts is:

[0037] After adding steel scrap into the converter, it is mixed into the molten iron of the blast furnace. The proportion of steel scrap added is 15-25%. During the process, slag is added and smelted by top-bottom double blowing. The tapping temperature of the converter is ≥1650°C; At the same time, add silicon-manganese alloy, ferroniobium, ferrosilicon nitride and common recarburizer in order, control C: 0.20-0.25wt%, Mn: 1.25-1.60wt%, Nb: 0.008-0.04wt%, N: 0.006 ~0.012%; the whole process from tapping to continuous casting adopts inert gas bottom blowing and stirring, the superheat of the continuous casting casting is controlled at 30-50 ℃, the cross-section of the billet is 150mm×150mm / 140mm×140mm billet, continuous casting The speed is 2.0-5.0m / min, and the continuous casting adopts enhanced water cooling operation; the billet heating temperature is controlled at 950-1200°C, the soaking temperature is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com