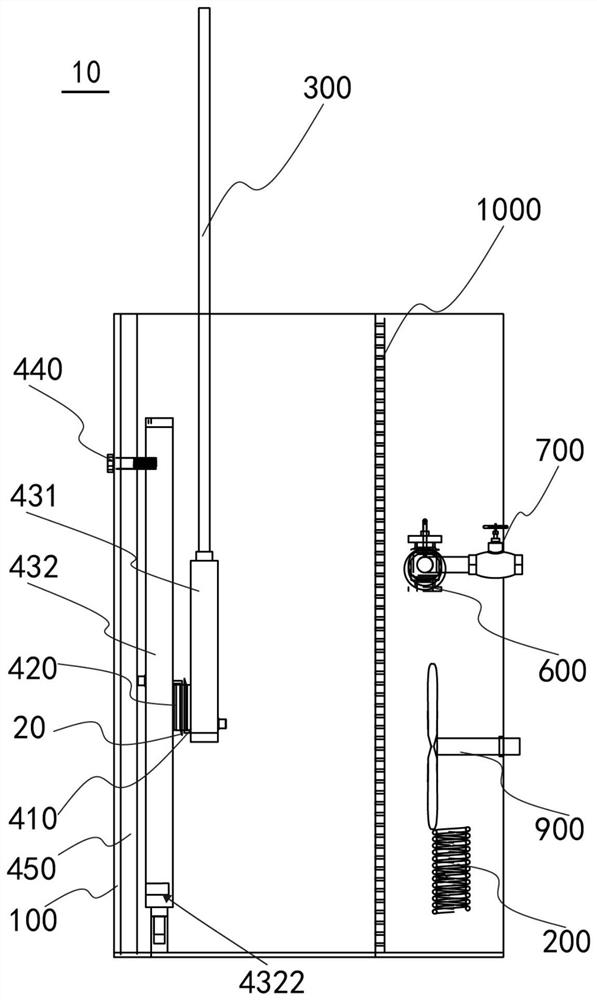

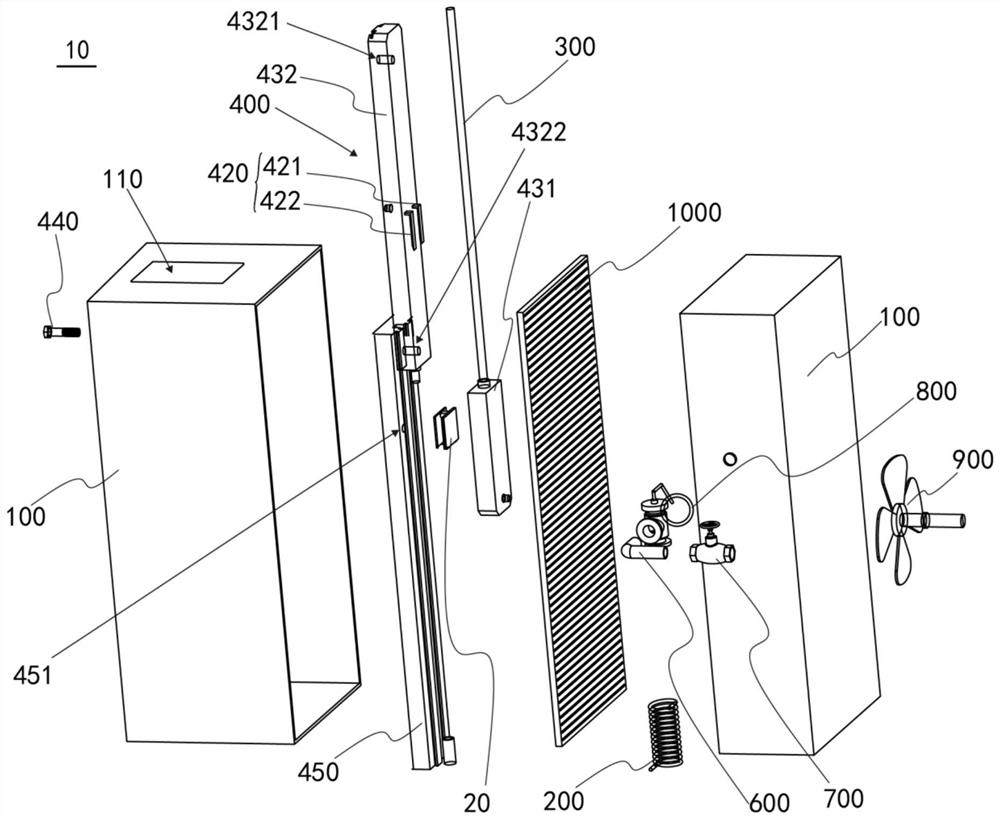

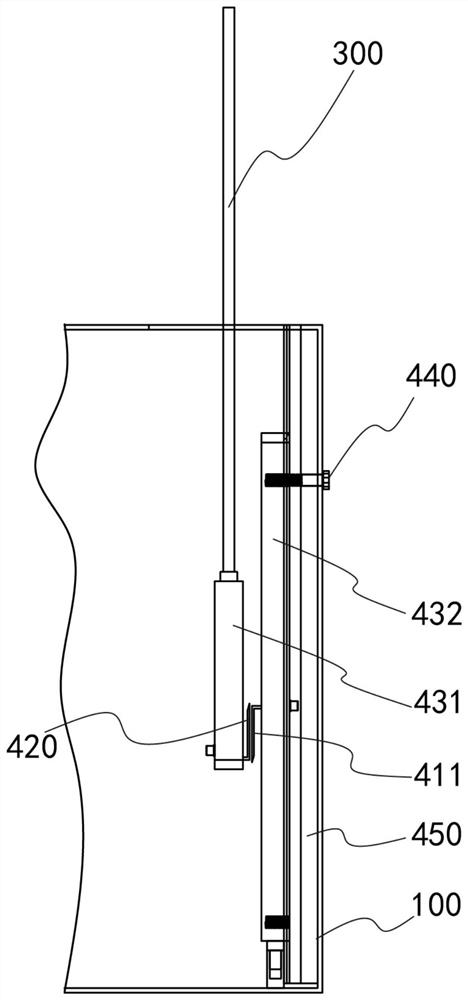

Artificial accelerated aging system for sealant and artificial accelerated aging method for sealant

An accelerated aging and sealant technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, using mechanical devices, instruments, etc., can solve the problems that the detection performance of silicone structural sealants cannot be achieved, and achieve wide applicability, The effect of improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This embodiment provides an artificial accelerated aging method for sealant using the above-mentioned artificial accelerated aging system 10 for sealant. This embodiment simulates the environment of a rainy area with a large temperature difference between day and night.

[0079] The structure of the test piece 20 includes a first substrate 21 , a second substrate 23 and a sealant 22 , the first substrate 21 is a glass plate, the sealant 22 is a silicone structural sealant, and the second substrate 23 is an aluminum plate. The sealant 22 is located between the first substrate 21 and the second substrate 23 , and the first substrate 21 , the second substrate 23 and the sealant 22 form an "I" shape. It is not difficult to understand that the first substrate 21 and the second substrate 23 in the test piece 20 can also be other plate materials. At the same time, the positions of the first substrate 21 and the second substrate 23 can be reversed, and they can also be both the ...

Embodiment 2

[0082] This embodiment provides an artificial accelerated aging method for sealant using the above-mentioned artificial accelerated aging system 10 for sealant. This embodiment simulates the environment in an acid rainy and windy area.

[0083] The structure of the test piece 20 includes a first substrate 21 , a second substrate 23 and a sealant 22 , the first substrate 21 is a glass plate, the sealant 22 is a silicone structural sealant, and the second substrate 23 is an aluminum plate. The sealant 22 is located between the first substrate 21 and the second substrate 23 , and the first substrate 21 , the second substrate 23 and the sealant 22 form an "I" shape. It is not difficult to understand that the first substrate 21 and the second substrate 23 in the test piece 20 can also be other plate materials. At the same time, the positions of the first substrate 21 and the second substrate 23 can be reversed, and they can also be both the first substrate 21 or the second substrate...

Embodiment 3

[0086] This embodiment provides an artificial accelerated aging method for sealant using the above-mentioned artificial accelerated aging system 10 for sealant. This embodiment simulates the environment of a seaside windy and humid area.

[0087] The structure of the test piece 20 includes a first substrate 21 , a second substrate 23 and a sealant 22 , the first substrate 21 is a glass plate, the sealant 22 is a silicone structural sealant, and the second substrate 23 is an aluminum plate. The sealant 22 is located between the first substrate 21 and the second substrate 23 , and the first substrate 21 , the second substrate 23 and the sealant 22 form an "I" shape. It is not difficult to understand that the first substrate 21 and the second substrate 23 in the test piece 20 can also be other plate materials. At the same time, the positions of the first substrate 21 and the second substrate 23 can be reversed, and they can also be both the first substrate 21 or the second substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com