Transparent flexible electrode thin film, manufacturing method thereof and transparent flexible electrode

A flexible electrode, transparent technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low substrate adhesion, high process cost, cumbersome process, etc., achieve high transmittance, simplify manufacturing process, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

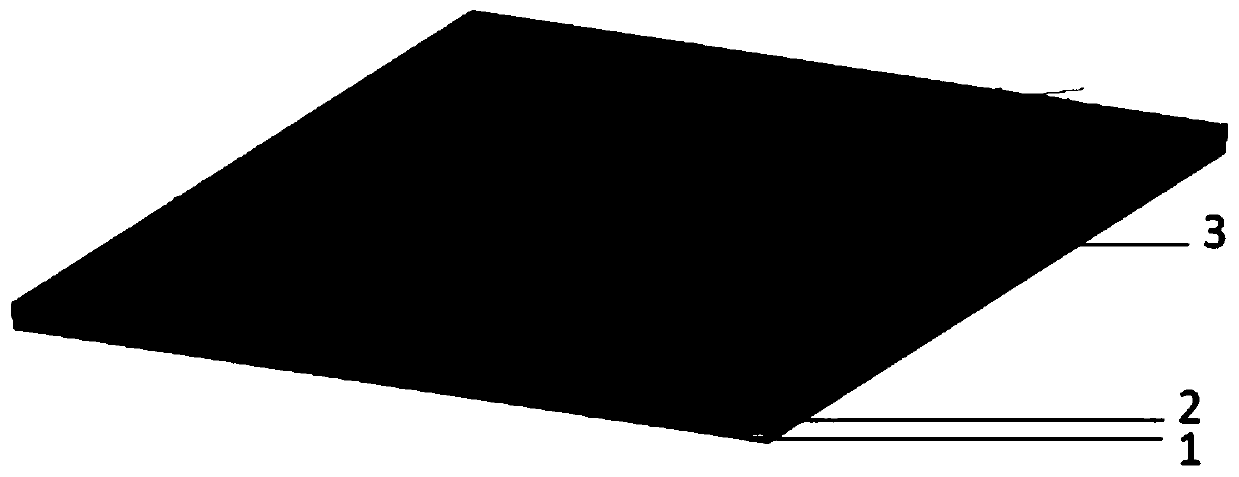

[0038] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

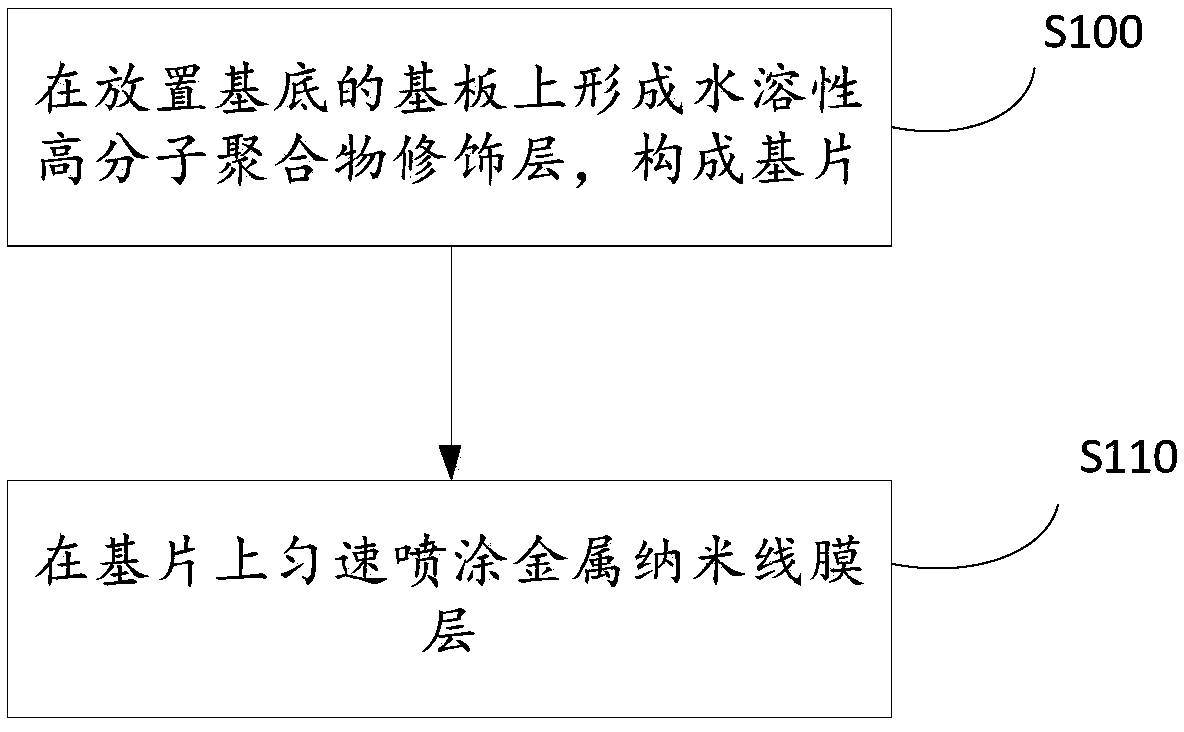

[0039] figure 1 A flowchart showing a method for manufacturing a transparent flexible electrode film according to an embodiment of the present invention. Preparation methods include:

[0040] Step S100: forming a polymer compound modification layer on the substrate on which the base is placed to form a substrate.

[0041] According to the specific implementation mode, various forming methods such as spin coating, drop coating, and scraping coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com