Amphiphilic hydroxyl magnetic bead, and preparation method and application thereof

An amphiphilic and hydroxyl technology, applied in the field of materials, can solve the problems of difficult to precisely control the hydrophobicity strength and hydrophobicity density, difficult to control the surface characteristics of magnetic beads, etc., to achieve less damage, mild reaction conditions, and particle size distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

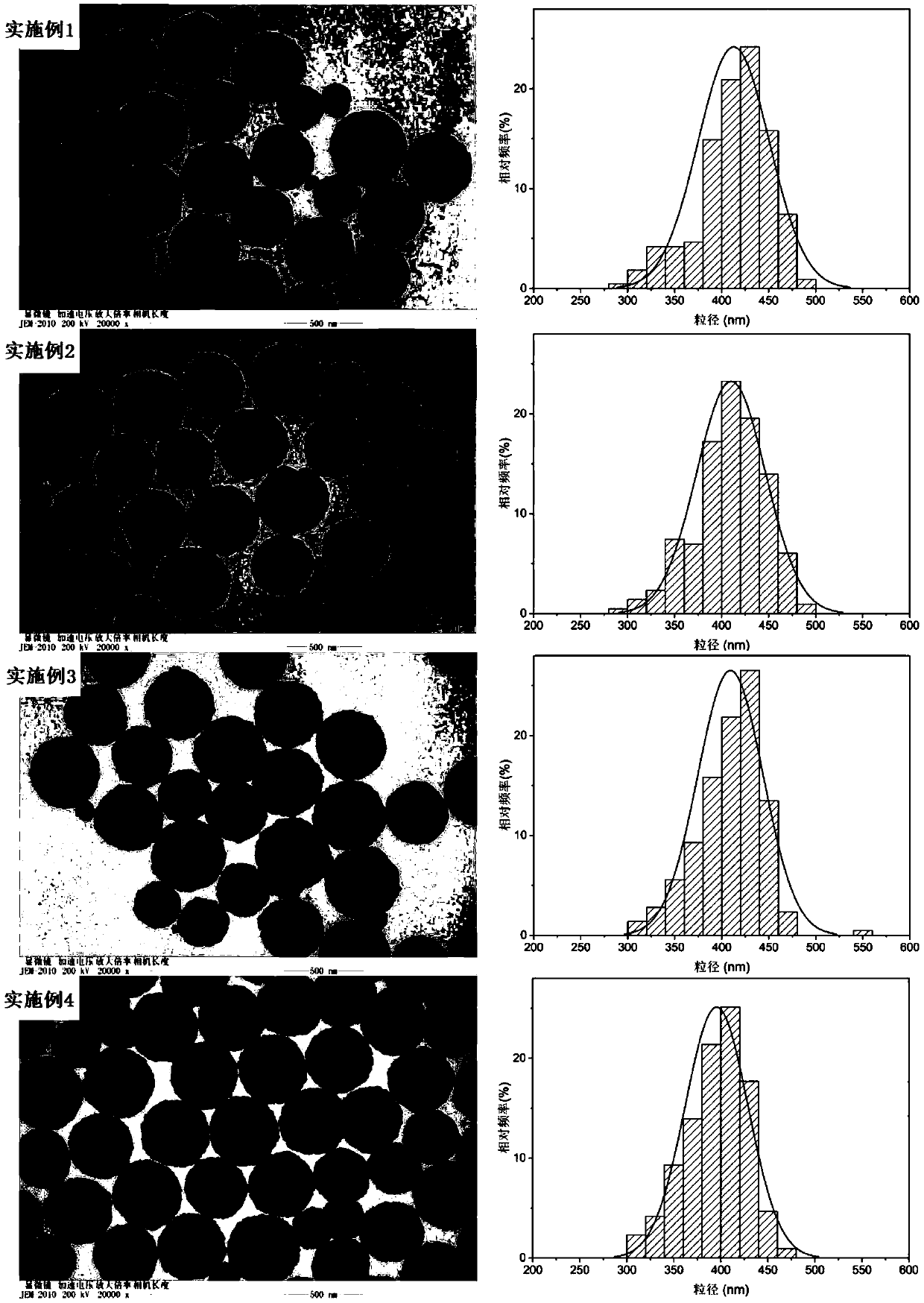

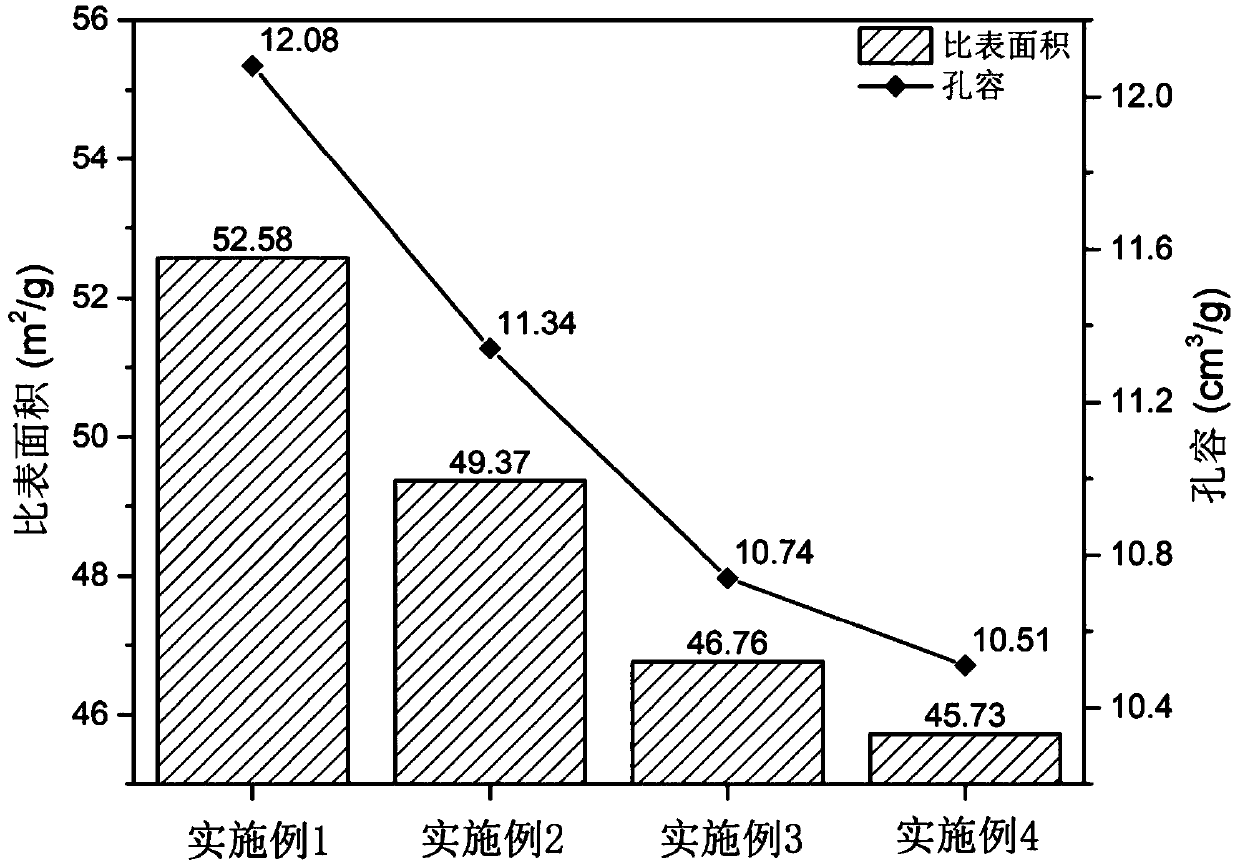

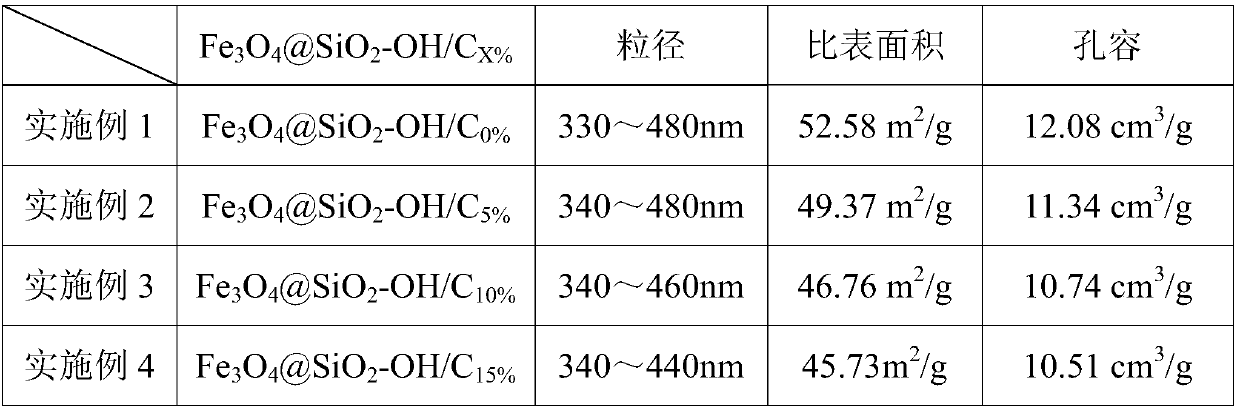

Embodiment 1

[0036] Controllable amphiphilic silanol magnetic beads Fe 3 o 4 @SiO 2 -OH / C 0% preparation method

[0037] First weigh 1g Fe 3 o 4Bare magnetic beads (made according to Li Yadong’s method) were put into a 2000mL three-neck flask, and 1000mL of ethanol, 250mL of water, 10mL of ammonia water, 8mL of tetraethoxysilane and 0mL of methyltrimethoxysilane were added to the three-necked flask, and ultrasonically dispersed for 30 minutes. uniform. The three-neck flask was heated in a water bath at 25°C, and mechanically stirred at a rate of 500 rpm for 24 hours. After the reaction was completed, it was lowered to room temperature to obtain a black magnetic bead suspension solution. After the above reaction solution was attracted by a strong magnet until the supernatant was colorless, the supernatant was discarded, the black precipitate was washed repeatedly with a mixture of water and ethanol, and the sample was placed in a drying oven at 70°C for 24 hours to obtain the controll...

Embodiment 2

[0040] Controllable amphiphilic silanol magnetic beads Fe 3 o 4 @SiO 2 -OH / C 5% preparation method

[0041] First weigh 1g Fe 3 o 4 Bare magnetic beads (self-made according to Li Yadong's method) were put into a 2000mL three-necked flask, and 1000mL of ethanol, 250mL of water, 10mL of ammonia water, 7.6mL of tetraethoxysilane and 0.4mL of methyltrimethoxysilane were added to the three-necked flask, and ultrasonically 30 minutes to disperse evenly. The three-neck flask was heated in a water bath at 25°C, and mechanically stirred at a rate of 500 rpm for 24 hours. After the reaction was completed, it was lowered to room temperature to obtain a black magnetic bead suspension solution. After the above reaction solution was attracted by a strong magnet until the supernatant was colorless, the supernatant was discarded, the black precipitate was washed repeatedly with a mixture of water and ethanol, and the sample was placed in a drying oven at 70°C for 24 hours to obtain the ...

Embodiment 3

[0044] Controllable amphiphilic silanol magnetic beads Fe 3 o 4 @SiO 2 -OH / C 10% preparation method

[0045] First weigh 1g Fe 3 o 4 Bare magnetic beads (self-made according to Li Yadong's method) were put into a 2000mL three-necked flask, and 1000mL of ethanol, 250mL of water, 10mL of ammonia water, 7.2mL of tetraethoxysilane and 0.8mL of methyltrimethoxysilane were added to the three-necked flask, and ultrasonically 30 minutes to disperse evenly. The three-neck flask was heated in a water bath at 25°C, and mechanically stirred at a rate of 500 rpm for 24 hours. After the reaction was completed, it was lowered to room temperature to obtain a black magnetic bead suspension solution. After the above reaction solution was attracted by a strong magnet until the supernatant was colorless, the supernatant was discarded, the black precipitate was washed repeatedly with a mixture of water and ethanol, and the sample was placed in a drying oven at 70°C for 24 hours to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com