Novel taper-free pumped optical fiber combiner structure

A technology of pumping optical fiber and beam combiner, which is applied in the direction of laser, optical waveguide coupling, laser components, etc., can solve the problems of difficult fiber pump source beam combining, poor mechanical stability of optical fiber, and easy breakage, etc., to improve pumping Brightness, High Manufacturability, Efficiency Avoided Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and example, specific embodiment of the present invention is described in further detail, and following example is used to illustrate the present invention, but is not intended to limit the scope of the present invention.

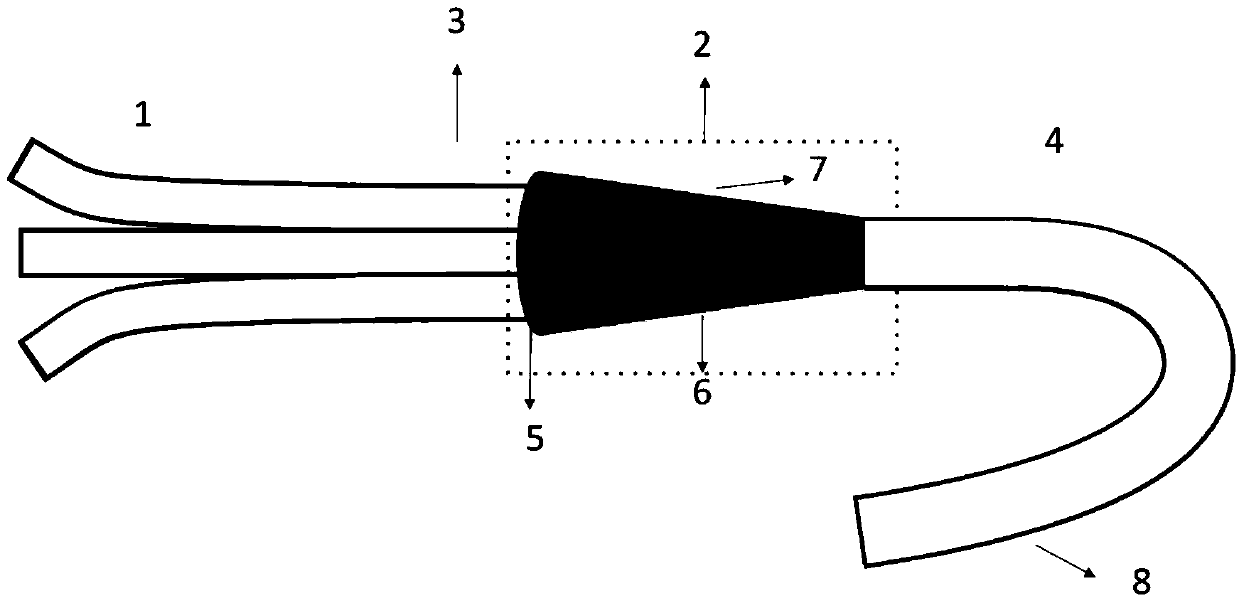

[0018] Such as figure 1 As shown, a new type of pump fiber combiner structure without taper, the fiber pump combiner is composed of at least one pump fiber 1, beam combining coupling device 2, fiber fixing device 3 and output device 4 combined.

[0019] The number of pumping optical fibers 1 is 1, 3, 7, 19 or 61 optical fibers with the same size, structure, numerical aperture and other characteristic parameters, which are the input ports of optical signals and are used for inputting optical signals. Specifically, each pumping fiber can be coupled with a semiconductor pumping laser.

[0020] The beam-combining coupling device 2 includes two parts, a convex mirror 5 and a tapered cylinder 6. The convex mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com