Systems and methods for treating a metal substrate

A metal substrate and system technology, applied in metal material coating process, coating, lithium carbonate; layers and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

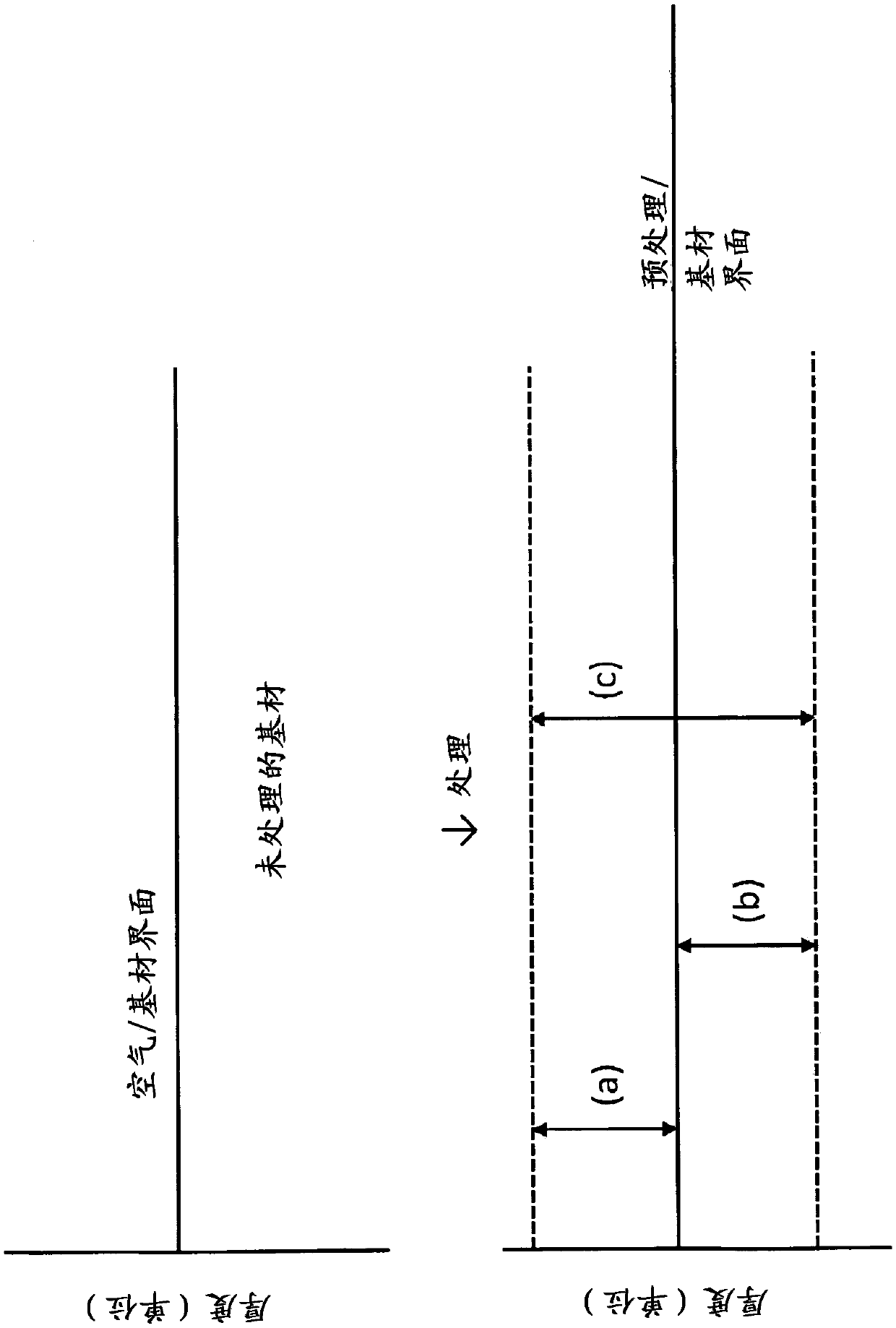

Method used

Image

Examples

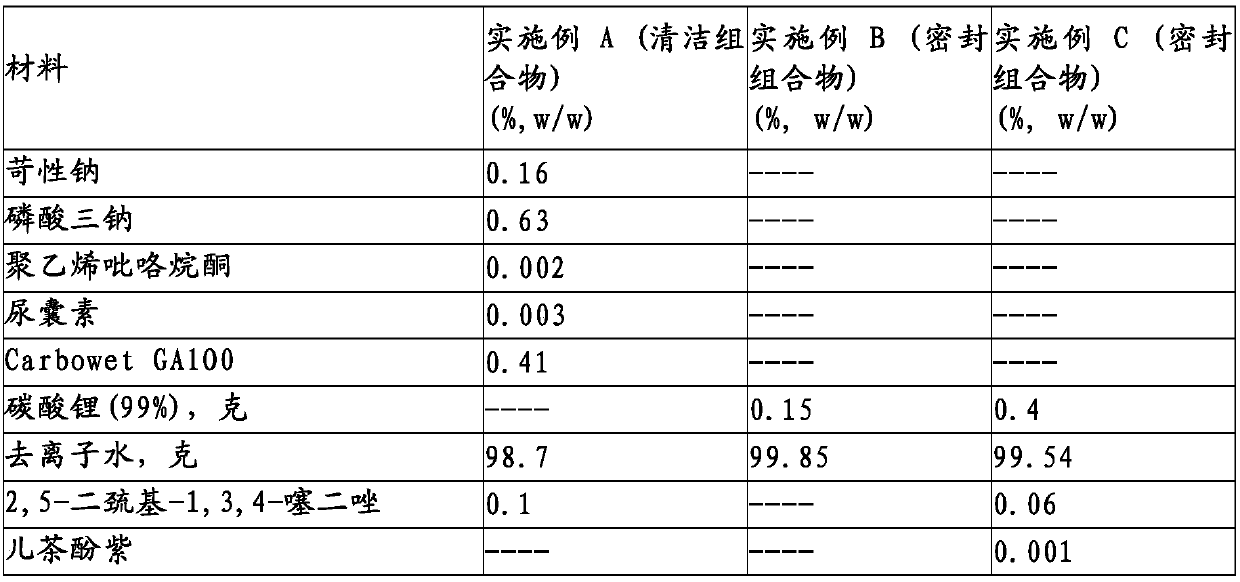

Embodiment 1

[0201] Three aluminum 2024T3 bare substrates (Priority Metals, Orange County, CA), each measuring 3" x 10" x 0.032", were hand wiped with methyl ethyl ketone (100%) and a disposable cloth, and air dried, This was followed by chemical cleaning. Each plate was immersed in a bath containing SOCOCLEAN A3432 (a commercially available cleaning composition from Socomore, prepared according to the manufacturer's instructions) for 10 minutes at 55° C. under agitation. Then rinse with deionized water Each panel was spray rinsed for 30 seconds, followed immediately by immersion in deionized water rinse for 2 minutes. After immersion rinse, each panel was immersed in SOCOSURF Al858-Al806 containing SOCOSURF Al858-Al806 (commercially available from Socomore) with agitation. agent, prepared according to the manufacturer's instructions) for 5 minutes. Each panel was then spray rinsed with deionized water for 30 seconds and immediately immersed in a deionized water rinse for 2 minutes. After t...

Embodiment 2

[0203] Three aluminum 2024T3 bare substrates (Priority Metals, Orange County, CA), each measuring 3" x 10" x 0.032", were hand wiped with methyl ethyl ketone (100%) and a disposable cloth, and air dried, This was followed by chemical cleaning. Each plate was immersed in a bath containing SOCOCLEAN A3432 (a commercially available cleaning composition from Socomore, prepared according to the manufacturer's instructions) for 10 minutes at 55° C. under agitation. Then rinse with deionized water Each panel was spray rinsed for 30 seconds, followed immediately by immersion in deionized water rinse for 2 minutes. After immersion rinse, each panel was immersed in SOCOSURF Al858-Al806 containing SOCOSURF Al858-Al806 (commercially available from Socomore) with agitation. agent, prepared according to the manufacturer's instructions) for 5 minutes. Each panel was then spray rinsed with deionized water for 30 seconds and immediately immersed in a deionized water rinse for 2 minutes. After i...

Embodiment 3

[0205] Three aluminum 2024T3 bare substrates (Priority Metals, Orange County, CA), each measuring 3" x 10" x 0.032", were hand wiped with methyl ethyl ketone (100%) and a disposable cloth, and air dried, This was followed by chemical cleaning. Each plate was immersed in a bath containing SOCOCLEAN A3432 (a commercially available cleaning composition from Socomore, prepared according to the manufacturer's instructions) for 10 minutes at 55° C. under agitation. Then rinse with deionized water Each panel was spray rinsed for 30 seconds, followed immediately by immersion in deionized water rinse for 2 minutes. After immersion rinse, each panel was immersed in SOCOSURF Al858-Al806 containing SOCOSURF Al858-Al806 (commercially available from Socomore) with agitation. agent, prepared according to the manufacturer's instructions) for 5 minutes. Each panel was then spray rinsed with deionized water for 30 seconds and immediately immersed in a deionized water rinse for 2 minutes. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com