Processing process of anchovy protein milk

A processing technology, anchovy technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of waste, not being able to be processed and utilized well, and achieve the effect of expanding utilization channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment relates to a processing technology of anchovy protein milk, comprising the following steps:

[0025] (1) Wash and divide the anchovies, remove the head, tail, fish bones, fish scales, keep the fish meat and viscera, mix the fish meat and viscera in a mass ratio of 5:1, grind them into surimi, add 2 times the weight of pure water , cook for 50 minutes, then keep the material temperature at 30°C, inoculate microorganisms, the microorganisms are Bifidobacterium and Lactobacillus casei, mix well, then add raw milk, the mass ratio of raw milk and anchovy fish meat is 3:10; 30°C , fermented for 5 days.

[0026] (2) Warm up the fermented material in step (1) to 65°C, keep it for 3 hours, cool to 45°C, add compound enzyme for enzymolysis; the dosage of compound enzyme is 1200U per milliliter of fermented material, and use malic acid or lemon for fermented material Acid to adjust the pH to 5, compound enzymes are cathepsin and pepsin; enzymatic hydrolysis for 6h...

Embodiment 2

[0034] This embodiment relates to a processing technology of anchovy protein milk, comprising the following steps:

[0035] (1) Wash and divide the anchovies, remove the head, tail, fish bones and fish scales, keep the fish meat and viscera, mix the fish meat and viscera in a mass ratio of 2:1, grind them into surimi, and add 2 times the weight of pure water , cook for 30 minutes, then keep the material temperature at 25°C, inoculate microorganisms, the microorganisms are Bifidobacterium and Lactobacillus casei, mix well, then add raw milk, the mass ratio of raw milk and anchovy fish meat is 1:10; 25°C , fermented for 3 days.

[0036] (2) Warm up the fermentation material in step (1) to 50°C, maintain it for 1 hour, cool to 42°C, add compound enzyme for enzymolysis; the dosage of compound enzyme is 500U per milliliter of fermentation material, and use malic acid or lemon for fermentation material Acid to adjust the pH to 3.5, compound enzymes are cathepsin and pepsin; enzymat...

Embodiment 3

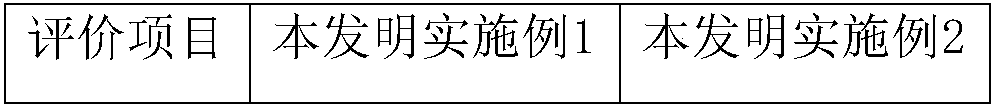

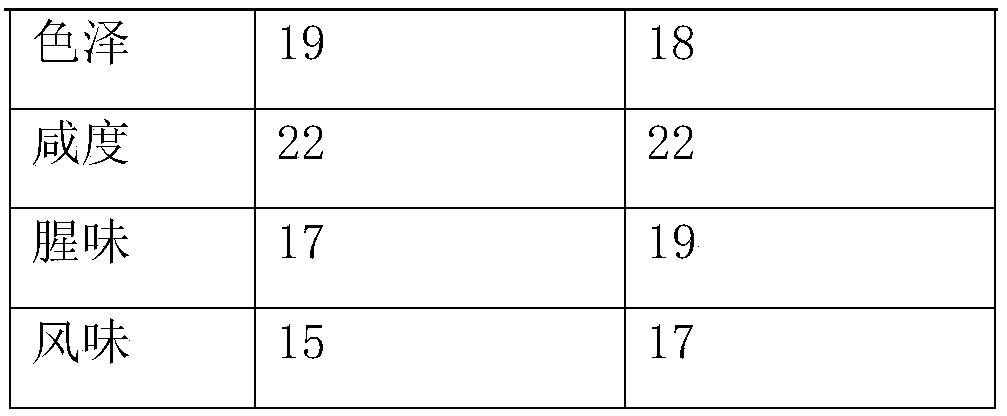

[0044] The sensory identification of the filtrate of embodiment 3 steps (4)

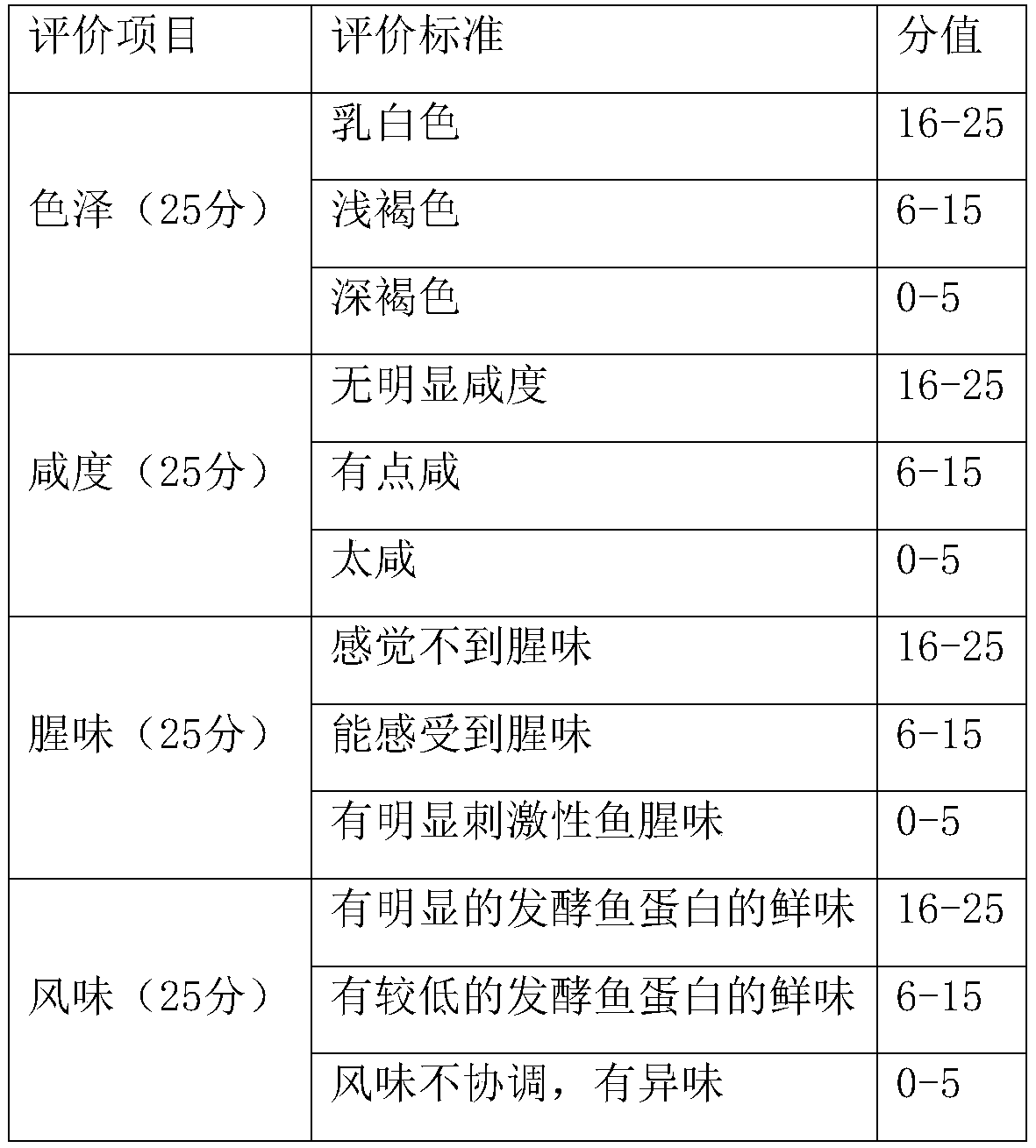

[0045] The mouthfeel of the anchovy hydrolyzed protein liquid of the present invention was evaluated by sensory. The higher the score, the better the effect. The specific evaluation criteria are shown in the table below, and the sum of the scores is the average value.

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com