Low-fat fruit and vegetable crispy chips and processing method thereof

A technology for fruit and vegetable chips and a processing method, applied in the field of food processing, can solve the problems of rancidity, loss of nutrients and the like, and achieve the effects of good quality, crisp taste and unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The processing method of low-fat fruit and vegetable chips includes the following steps:

[0071] Step a: Selection of raw materials: choose fresh carrots as raw materials;

[0072] Step b ripening: cut the carrots into slices with a thickness of 2 cm, and bake them in a microwave oven with a power of 1200W for 15 minutes to ripen;

[0073] Step c crushing into puree: crushing the matured carrots into puree to obtain carrot puree;

[0074] Step d: Adding auxiliary materials: adding β-cyclodextrin, whey powder and wheat cellulose to the carrot puree, and mixing uniformly to obtain a mixture; the carrot puree, β-cyclodextrin, whey powder and wheat cellulose The weight ratio is 39:6:4:1;

[0075] Step e: Forming: the mixture is pressed into a composite sheet with a thickness of 5mm using a tablet press;

[0076] Step f puffing: air puffing the composite sheet;

[0077] Step g drying: infrared drying the composite sheet after the airflow expansion, the infrared drying temperature is 8...

Embodiment 2

[0079] The processing method of low-fat fruit and vegetable chips includes the following steps:

[0080] Step a: Selection of raw materials: choose fresh carrots as raw materials;

[0081] Step b Ethanol fumigation: Put the carrots in a closed room and fumigate them with 400μL / L ethanol aqueous solution at 25℃ for 6 hours; then take the carrots out and place them in a ventilated environment for 2 hours to obtain ethanol fumigation Carrots

[0082] Step c ripening: cut the carrots fumigated with ethanol into thin slices with a thickness of 2 cm, and bake them in a microwave oven with a power of 1200W for 15 minutes to ripen them;

[0083] Step d crushing into puree: crushing the matured carrots into puree to obtain carrot puree;

[0084] Step e: Adding auxiliary materials: adding β-cyclodextrin, whey powder and wheat cellulose to the carrot puree, and mixing uniformly to obtain a mixture; the carrot puree, β-cyclodextrin, whey powder and wheat cellulose The weight ratio is 39:6:4:1;

[...

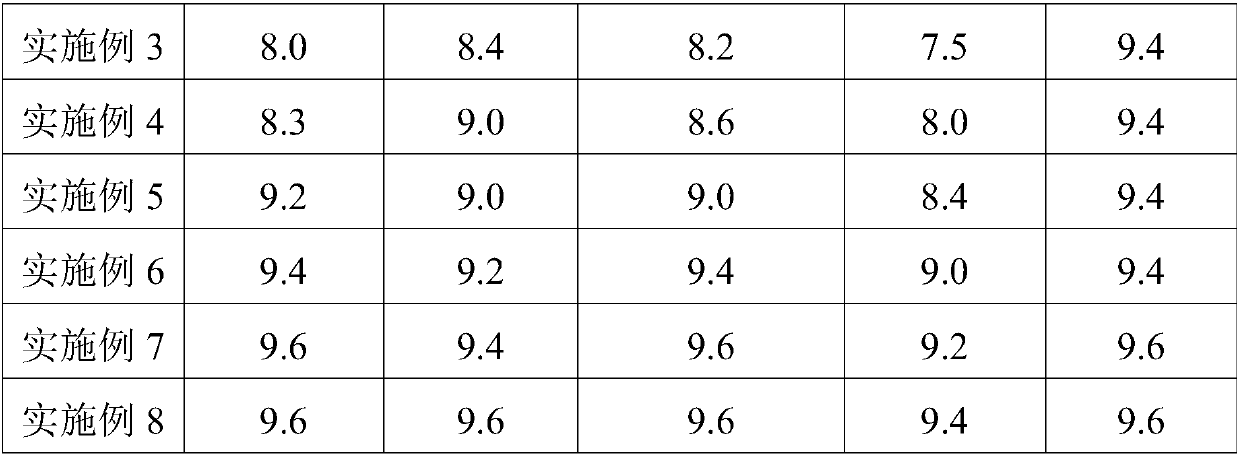

Embodiment 3

[0089] The processing method of low-fat fruit and vegetable chips includes the following steps:

[0090] Step a: Selection of raw materials: choose fresh carrots as raw materials;

[0091] Step b Ethanol fumigation: Put the carrots in a closed room and fumigate them with 400μL / L ethanol aqueous solution at 25℃ for 6 hours; then take the carrots out and place them in a ventilated environment for 2 hours to obtain ethanol fumigation Carrots

[0092] Step c color protection and enzyme inhibition treatment: the carrots fumigated with ethanol are immersed in the color protection and enzyme inhibition treatment solution for 30 seconds, taken out, and drained to obtain color protection and enzyme inhibition carrots;

[0093] Step d Maturation: Cut the color-protected and enzyme-protected carrots into slices with a thickness of 2 cm, and roast them in a microwave oven with a power of 1200W for 15 minutes to mature;

[0094] Step e: crushing into puree: crushing the matured carrots into puree t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com