A bio-ink with uniform cell distribution based on 3D printing and its assembly method

A bio-ink, 3D printing technology, applied in prosthesis, additive processing, medical science and other directions, can solve the problem of uneven cell distribution, achieve the effect of slowing down cell deposition, facilitating printing and maintaining biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

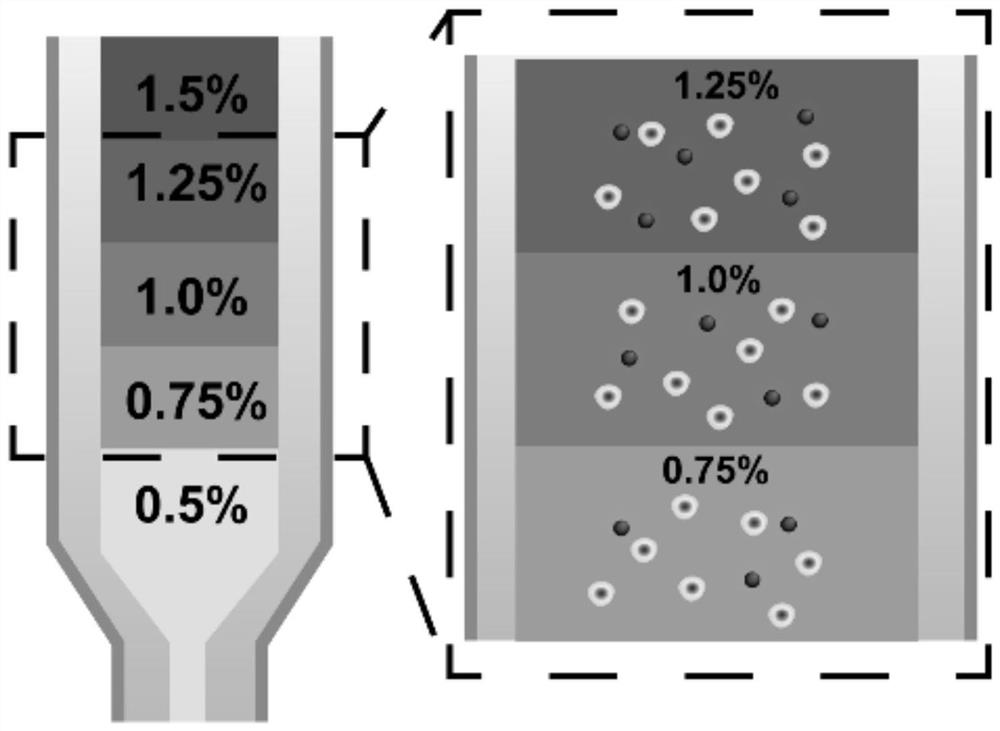

[0051] The bioink body A of the embodiment of the present invention is made up of the following mass fraction components:

[0052] Methacrylated Gelatin 7%;

[0053] Silk protein microspheres 0.5%, particle size 0.1mm;

[0054] Fetal bovine serum 1%;

[0055] Photoinitiator 2959 0.1%;

[0056] HEPES Equilibrium Buffer 91.6%, pH=7.2.

[0057] The preparation method of the bio-ink body A of the embodiment of the present invention is as follows: dissolve the methacrylic anhydride gelatin in the HEPES equilibrium buffer solution according to the above ratio, add photoinitiator 2959, and stir at 50°C to obtain a uniformly mixed solution. Filter and sterilize with PES membrane filter, then cool down to 37°C, finally add silk protein and fetal bovine serum, and mix evenly by ultrasonic.

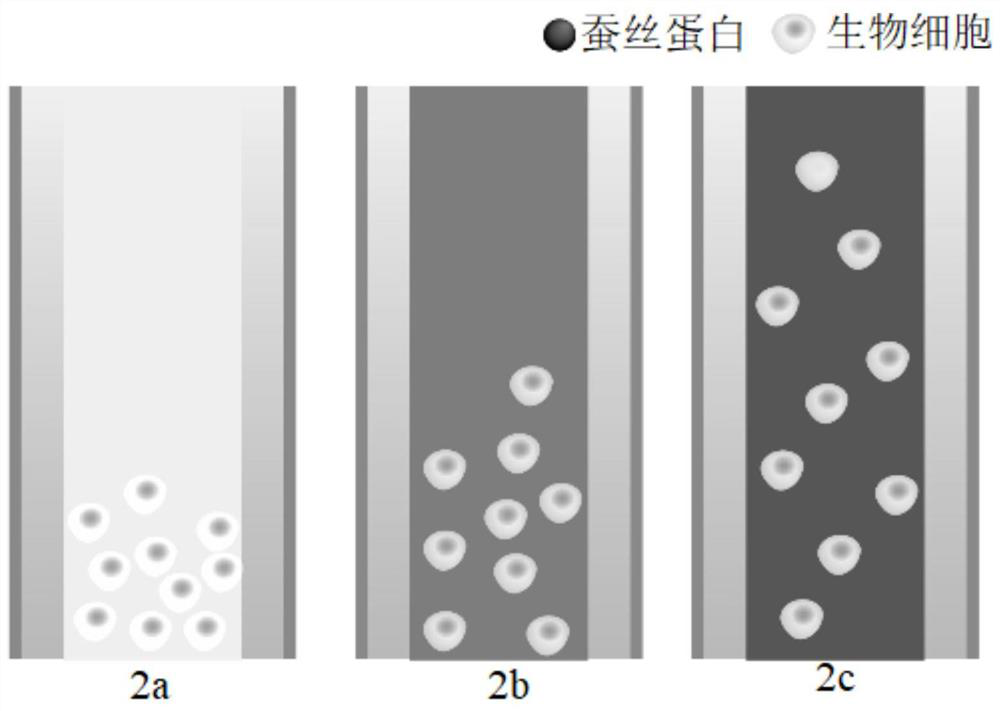

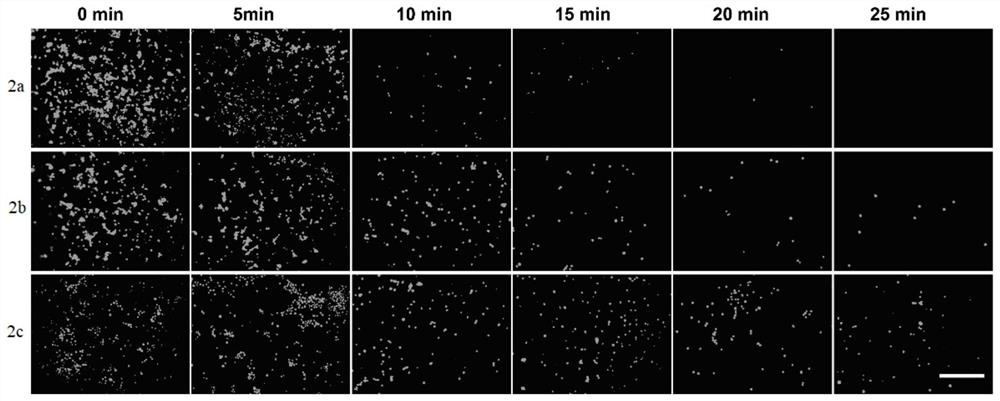

[0058] Will 1╳10 6 A bioactive cell was added to the prepared bio-ink body A and mixed evenly to obtain bio-ink A.

Embodiment 2

[0060] The bioink body B of the embodiment of the present invention is made up of the following mass fraction components:

[0061] Methacrylated Gelatin 7%;

[0062] Silk protein microspheres 0.75%, particle size 0.1mm;

[0063] Fetal bovine serum 1%;

[0064] Photoinitiator 2959 0.1%;

[0065] HEPES Equilibrium Buffer 91.15%, pH=7.2.

[0066] The preparation method of the bio-ink body B of the embodiment of the present invention is the same as that of embodiment 1.

[0067] Will 1╳10 6 A bioactive cell was added to the prepared bio-ink body B and mixed evenly to obtain bio-ink B.

Embodiment 3

[0069] The bioink body C of the embodiment of the present invention is made up of the following mass fraction components:

[0070] Methacrylated Gelatin 7%;

[0071] Silk protein microspheres 1%, particle size 0.1mm;

[0072] Fetal bovine serum 1%;

[0073] Photoinitiator 2959 0.1%;

[0074] HEPES Equilibrium Buffer 90.9%, pH=7.2.

[0075] The preparation method of the bio-ink body C of the embodiment of the present invention is the same as that of the embodiment 1.

[0076] Will 1╳10 6 A bioactive cell is added to the prepared bio-ink body C and mixed evenly to obtain bio-ink C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com