Vertical anti-dewatering cutting machine of asbestos cement plate

A cement board and cutting machine technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of large impact force, unusable, temperature rise, etc., to reduce impact force, avoid cracks, and reduce fractures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

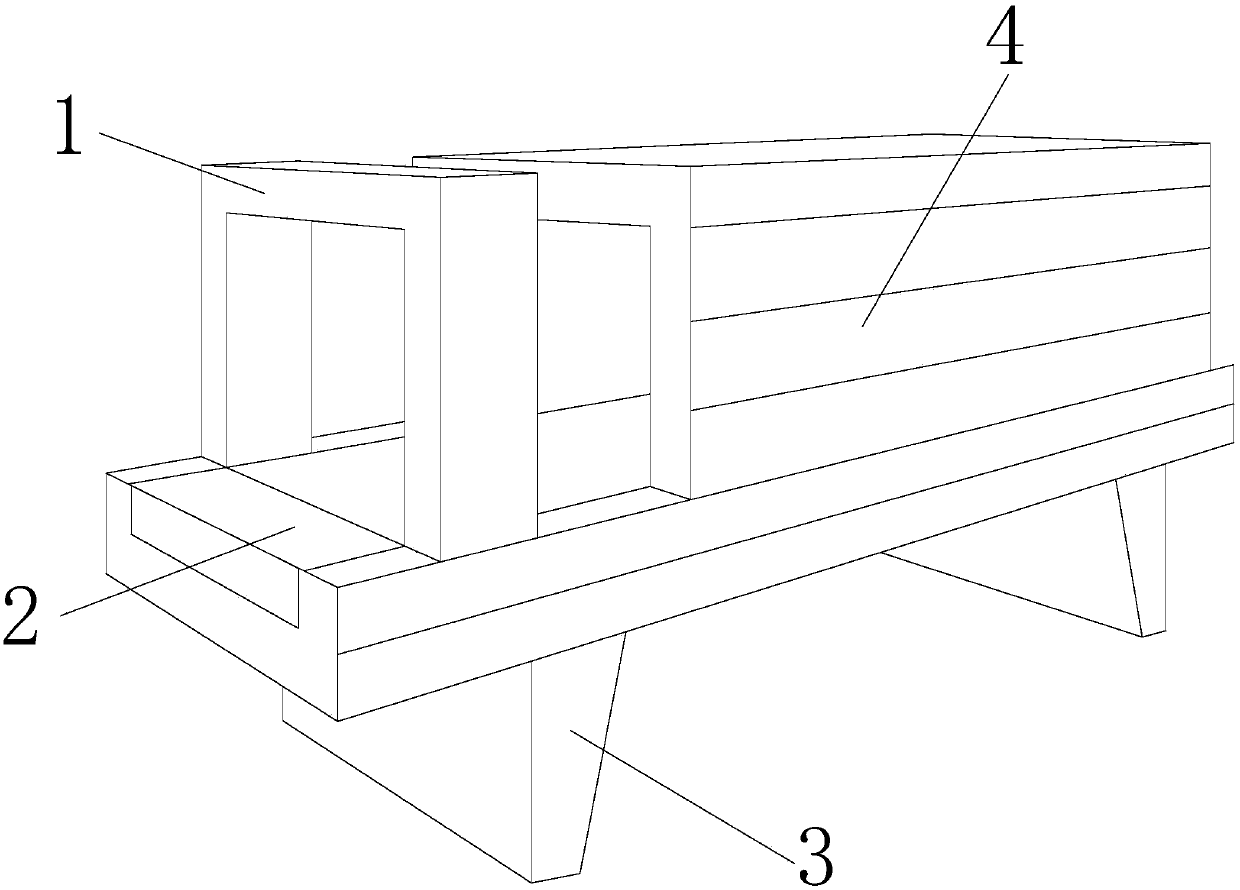

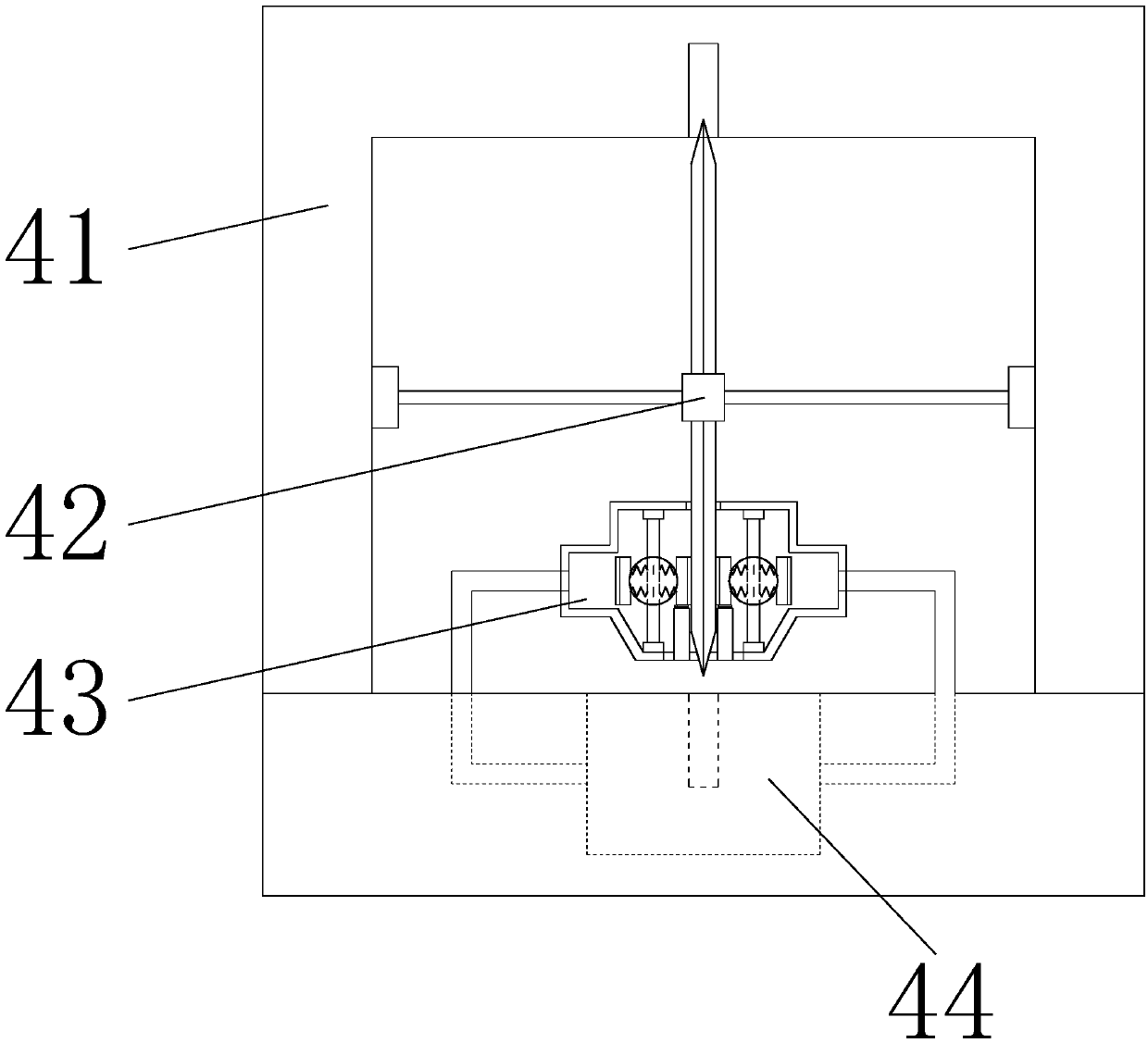

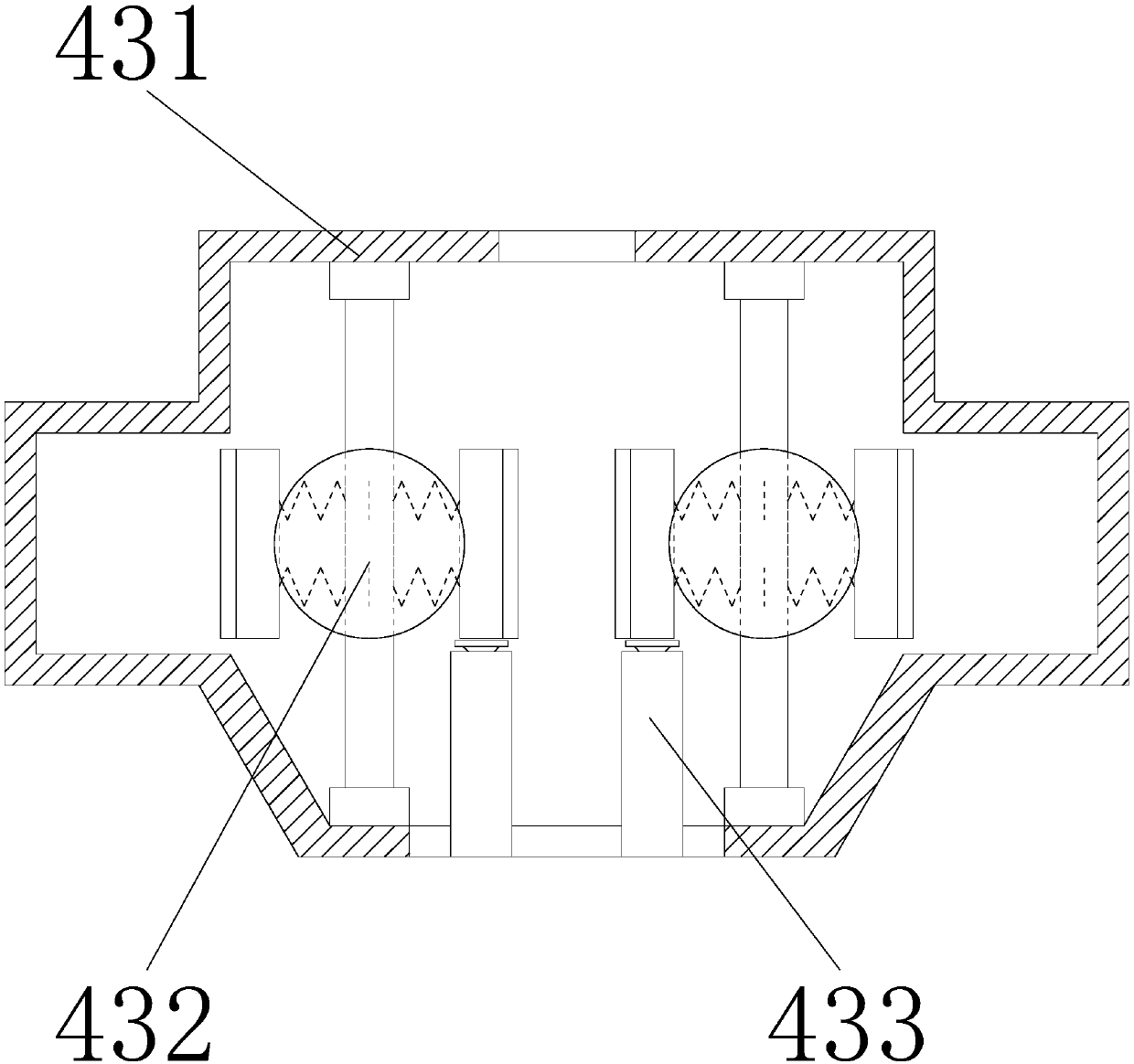

[0021] see Figure 1-Figure 7 , a vertical anti-dehydration cutting machine for asbestos cement board according to the present invention, its structure includes a cement board limit frame 1, a cement board transmission machine 2, a support foot 3, an asbestos cement board cutting machine 4, the cement board limit frame 1 It is fixedly installed at the head end of the cement board transmission machine 2. There are two support feet 3 and they are fixedly welded to the front and rear ends of the cement board transmission machine 2. The asbestos cement board cutting machine 4 is fixedly installed on the cement board transmission machine 2. At the end, the asbestos cement board cutting machine 4 and the cement board limit frame 1 are parallel to each other, and the asbestos cement board cutting machine 4 includes a dustproof outer frame 41, a high-speed cutting tool 42, an anti-crack protection mechanism 43, and an anti-breakage of the cutting edge. Mechanism 44, a high-speed cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com